10 Costly Installation Mistakes and How We Prevent Them

Intruduction: Why Precision in Installation Matters

When it comes to custom cabinetry, stonework, or architectural panels, installation is not just the final step, it’s the make-or-break moment. At Medalco, we’ve spent years perfecting our craft, from waterjet cutting to custom fabrication, ensuring that every piece we produce fits like a glove and performs beautifully for decades.

However, we’ve seen how even the best materials can be compromised by poor installation practices. Whether it’s a luxury kitchen countertop, a marble fireplace surround, or glass inlays for commercial interiors, the way it’s installed will determine not only how it looks on day one but also how it stands the test of time.

That’s why we’ve put together this list of the 10 most common installation mistakes, and how Medalco’s approach eliminates them. We’ll share real-world case studies from our projects, highlight the behavior of materials like stone, metal, wood, and glass, and show why precision, patience, and planning matter.

Mistake 1: Inaccurate Measurements

If you’ve ever tried to fit a custom-made countertop only to find it’s a quarter-inch too short, you know how heartbreaking it can be. Measurement errors are the number one cause of costly delays and rework in the installation world.

Why it Happens:

- Using old or inconsistent measuring tools.

- Not accounting for wall irregularities or out-of-square corners.

- Forgetting to factor in trim, expansion gaps, or hardware placement.

Material Behavior:

- Stone: Can’t be “stretched” to fit; adjustments often mean expensive recutting.

- Wood: May swell or shrink with humidity, so allowances are essential.

- Glass: Fragile; overcutting means a complete remake.

Medalco’s Solution:

At Medalco, we combine laser-guided measuring tools with on-site verification before fabrication begins. We create digital templates for every custom piece, which are then directly fed into our CNC and waterjet systems, ensuring flawless precision.

Case Study:

A client in San Jose wanted a custom quartzite island top with a unique waterjet-cut edge profile. The space was slightly irregular due to an older home’s construction. By using our 3D laser scanning process, we identified a subtle 3/8-inch deviation in one wall. This early detection meant we could adjust the cut before fabrication, saving the client a two-week delay and the cost of remaking the entire slab.

Mistake 2: Ignoring Material Expansion and Contraction

Different materials respond differently to temperature and humidity changes. Ignoring this fact can lead to cracks, warping, or buckling.

Why it Happens:

- Installers assume all materials behave the same.

- Lack of climate control awareness during installation.

Material Behavior:

- Wood: Expands in humidity, contracts in dry air — especially relevant for cabinet doors and panels.

- Metal: Expands with heat; stainless steel countertops in sunny areas can shift slightly.

- Stone: Stable, but large spans may still move slightly with temperature changes.

Medalco’s Solution:

We design with micro-gaps and flexible adhesives where needed. Our waterjet precision allows us to create parts that look seamless but still have built-in tolerance for expansion.

Case Study:

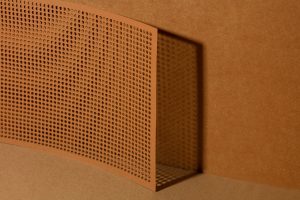

In a Silicon Valley tech office, we installed an intricate waterjet-cut metal feature wall. Because the wall received direct sunlight for several hours a day, we engineered tiny expansion gaps that were invisible to the eye but prevented warping over time.

Mistake 3: Improper Substrate Preparation

Even the most beautiful marble slab will fail if the surface underneath is uneven or unstable.

Why it Happens:

- Rushing to meet deadlines.

- Assuming the existing substrate is flat and secure.

Material Behavior:

- Stone & Tile: Require a stable, level surface to avoid cracking.

- Wood: Can adapt slightly but will show alignment issues if substrate is uneven.

- Glass Panels: Demand perfect flatness to prevent stress points.

Medalco’s Solution:

We perform a full substrate inspection before any installation begins. If we detect unevenness, we level and reinforce the base before continuing.

Case Study:

For a high-end kitchen renovation in Los Gatos, we were tasked with installing a solid marble backsplash with waterjet-cut floral patterns. The wall behind was uneven due to previous tile removal. We spent a full day preparing the wall to a laser-verified flatness before setting the marble. The result? Perfect alignment across the entire design, with no visible seams.

Mistake 4: Using the Wrong Adhesives or Fasteners

The bonding method is just as critical as the material itself. Using the wrong adhesive or fastener can lead to premature failure, staining, or structural issues.

Why it Happens:

- Assuming “one glue fits all.”

- Using cheaper, general-purpose adhesives instead of stone-specific or wood-specific products.

- Not accounting for environmental exposure like moisture, heat, or UV light.

Material Behavior:

- Stone: Needs non-staining adhesives to avoid discoloration on porous surfaces like marble.

- Wood: Requires adhesives that move with seasonal expansion.

- Glass: Needs flexible, transparent adhesives to maintain aesthetics.

Medalco’s Solution:

We match every project with the right adhesive or mechanical fastener based on the material, location, and environmental conditions. For instance, our epoxy resins for stone are UV-stable and our wood glues remain flexible to avoid joint cracking.

Case Study:

A client in Palo Alto needed an outdoor kitchen with a granite countertop. We used a marine-grade adhesive resistant to heat and moisture, ensuring the joints stayed flawless even after two years of exposure to California’s sun and winter rains.

Mistake 5: Poor Alignment and Leveling

Even if every piece is cut perfectly, poor alignment during installation can ruin the overall look and function.

Why it Happens:

- Skipping laser-leveling tools in favor of “eyeballing” it.

- Working too fast without checking alignment at each stage.

Material Behavior:

- Stone slabs: Once glued, adjustments are difficult or impossible.

- Cabinetry: Misalignment can cause doors to swing open or not close properly.

- Tile patterns: Even 1–2 mm of misalignment can disrupt the visual flow.

Medalco’s Solution:

We use digital laser levels and check alignment multiple times during installation. Our teams work in pairs — one places, one verifies, so there’s no “oops” moment at the end.

Case Study:

For a waterjet-cut mosaic backsplash in Cupertino, the pattern was geometric with extremely thin grout lines. We took the extra time to adjust each panel with precision, resulting in a seamless flow that looked like a single continuous piece.

Mistake 6: Ignoring Sealing and Finishing Needs

Many beautiful installations deteriorate quickly because the surfaces were not properly sealed or finished at the end.

Why it Happens:

- Assumption that factory finishes are permanent.

- Rushing to complete the project without protective measures.

Material Behavior:

- Natural stone: Can absorb liquids and stain without sealing.

- Wood: Requires protective coatings to prevent scratches and warping.

- Metal: May oxidize or tarnish without a protective layer.

Medalco’s Solution:

We always perform final sealing on-site after installation, using premium products matched to each material. For stone, we apply penetrating sealers; for wood, we use UV-resistant finishes; for metals, we add protective clear coats.

Case Study:

In a Menlo Park luxury spa, we installed a travertine steam room. Without sealing, travertine would have absorbed moisture and minerals. Our sealing process keeps it looking pristine even after thousands of hours of use.

Mistake 7: Overlooking Material Expansion and Contraction

Different materials expand and contract at different rates depending on temperature and humidity. Ignoring this can cause cracks, warping, or separation over time.

Why it Happens:

- Assuming rigid installations are always better.

- Not leaving expansion joints in stone or wood projects.

Material Behavior:

- Wood: Expands in humidity, contracts in dryness.

- Stone: Very minimal movement, but still affected by temperature extremes.

- Glass & Metal: React differently to heat, often expanding more than stone.

Medalco’s Solution:

We calculate thermal expansion allowances for every multi-material installation. Expansion joints, flexible adhesives, and hidden gap allowances ensure materials can “breathe” without damage.

Case Study:

We fabricated a waterjet-cut marble and brass floor medallion for a lobby in San Jose. Because metal expands more than marble, we allowed for hidden micro-gaps. Even after four years of seasonal temperature changes, there’s no visible shifting or cracking.

Mistake 8: Choosing the Wrong Material for the Environment

Not all materials perform equally in all conditions — the wrong choice can mean higher maintenance and shorter lifespan.

Why it Happens:

- Prioritizing aesthetics over durability.

- Not understanding how materials weather outdoors or in high-traffic areas.

Material Behavior:

- Marble: Luxurious indoors, but prone to etching outdoors.

- Granite: Extremely durable for both indoor and outdoor use.

- Wood: Needs careful selection and treatment for outdoor use.

Medalco’s Solution:

We advise clients on material suitability based on their exact conditions. Our team often presents side-by-side performance comparisons so clients can make informed decisions without surprises later.

Case Study:

A homeowner in Los Gatos wanted white marble steps leading to a garden. We recommended honed granite instead, same elegance, but far better resistance to outdoor staining and wear.

Mistake 9: Underestimating Structural Support

Heavy materials like stone and metal require proper substructure planning. Skipping this step risks sagging, cracking, or collapse.

Why it Happens:

- Assuming existing cabinetry or flooring can handle added weight.

- Not accounting for dynamic loads (e.g., people walking, doors opening).

Material Behavior:

- Granite slabs: Can weigh hundreds of pounds, need reinforced support.

- Glass panels: Require load distribution to prevent point stress cracks.

Medalco’s Solution:

We evaluate load capacity and design support systems before fabrication begins. For example, we might reinforce cabinets with hidden steel frames before installing a thick stone countertop.

Case Study:

In a Cupertino kitchen remodel, the client requested a 3-inch-thick quartzite island top. We built a custom steel support frame hidden inside the cabinetry, allowing for a dramatic overhang without risk.

Mistake 10: Rushing the Installation Timeline

Speed often compromises precision. While everyone wants fast results, hurrying an install can mean missed checks, improper curing, or unsafe shortcuts.

Why it Happens:

- Tight project deadlines.

- Misjudging curing/drying times for adhesives and sealants.

Material Behavior:

- Stone adhesives: Need proper curing to reach full strength.

- Wood finishes: Require drying time to avoid fingerprints, dust settling, or dull spots.

Medalco’s Solution:

We set realistic timelines and communicate them clearly to clients. Medalco never cuts curing times or skips final checks, because a perfect result is worth the wait.

Case Study:

A commercial lobby in Sunnyvale needed large-format porcelain slabs installed on a wall before a grand opening. We refused to rush curing times, instead staging the install over two phases. The opening went ahead, and the wall still looks flawless today.

Frequently Asked Questions (FAQs)

| 1. What makes Medalco’s installation process different from others? At Medalco, we don’t just install, we engineer every project. From assessing material behavior to allowing for thermal expansion, our process ensures that every installation is both visually stunning and structurally sound. |

| 2. How does Medalco prevent common installation mistakes? We use detailed project planning, precision waterjet cutting, and on-site quality checks. Every step is backed by our experience with stone, wood, glass, and metal, ensuring flawless results that last. |

| 3. Why is waterjet cutting important for precision installations? Waterjet cutting allows Medalco to create intricate designs without heat damage. This ensures perfect edge quality for materials like marble, granite, glass, and metal, making installation faster and more accurate. |

| 4. Can Medalco handle projects with multiple materials like wood, stone, and glass? Yes. Our team specializes in mixed-material fabrication. We understand how each material reacts to temperature, weight, and stress, and design our installations to accommodate these differences. |

| 5. How does Medalco ensure materials don’t warp or crack over time? We account for expansion and contraction, use the right adhesives, and incorporate hidden allowances in our designs. This proactive approach prevents future damage and keeps installations looking perfect. |

| 6. Does Medalco offer installation for outdoor projects? Absolutely. We carefully select materials suitable for the environment, such as weather-resistant granite or treated wood, ensuring long-term performance even in harsh outdoor conditions. |

| 7. How does Medalco reinforce heavy stone or metal installations? We assess structural support before fabrication. When necessary, we integrate hidden steel frames or reinforced bases so the final piece is both safe and beautiful. |

| 8. What’s the biggest mistake people make when choosing materials? Many choose based on looks alone. Medalco helps clients balance beauty and durability by showing real-world examples of how materials perform in specific environments. |

| 9. How long does a typical Medalco installation take? It depends on the complexity, but we never rush. We follow proper curing and setting times to ensure the work meets our high standards, quality always comes before speed. |

| 10. How can I start a project with Medalco? It’s easy, just contact us through our website or visit our showroom. We’ll discuss your vision, provide material and design options, and give you a transparent, step-by-step project plan. |

Trusted External Resources

- What Are 12 Common Cabinet Installation Mistakes to Avoid?

- Top 5 Issues With Kitchen Cabinet Installation

- The 7 Benefits of Precision Waterjet Cutting

- Benefits of Waterjet Technology | Waterjet Cutting Technology

- Water Jet Cutter