10 Important Tips for Choosing the Right MDF Thickness

Introduction

Medium Density Fiberboard, better known as MDF, has become one of the most trusted materials in modern furniture and cabinetry design. Its smooth surface, flexibility, and affordability make it a go-to choice for everything from closets to decorative wall panels. But there’s a critical factor that often gets overlooked: choosing the right MDF thickness. The thickness you select doesn’t just impact strength and stability, it affects aesthetics, functionality, and long-term durability.

At Medalco, where we specialize in custom fabrication and waterjet cutting, selecting the right MDF thickness is part of every design consultation. From closets and cabinetry to detailed stone-wood combinations, we help clients make choices that stand the test of time. This article explores 10 essential tips to guide you in selecting the right MDF thickness for your project, with insights from Medalco’s real-world case studies.

Table of contents

- 10 Important Tips for Choosing the Right MDF Thickness

- Introduction

- Why MDF Thickness Matters

- Tip 1: Match Thickness to Function

- Tip 2: Consider Long-Term Durability

- Tip 3: Balance Aesthetics with Practicality

- Tip 4: Think About Edge Banding

- Tip 5: Adapt Thickness to Material Combinations

- Tip 6: Account for Waterjet and CNC Cutting Behavior

- Tip 7: Factor in Installation Method

- Tip 8: Be Aware of Environmental Conditions

- Tip 9: Calculate Cost Efficiency

- Tip 10: Test Samples Before Committing

- Real-World Applications and Material Insights

- MDF and Glass: Lightness Meets Support

- MDF and Metal: Strength with a Modern Edge

- MDF and Wood: Harmony in Layers

- MDF in Decorative Waterjet Art Panels

- Case Study: Retail Space Transformation

- Case Study: Residential Custom Closet

- Engineering Precision in MDF Thickness

- Sustainability and Responsible MDF Choices

- Fabrication Techniques that Maximize MDF Performance

- MDF Thickness and Structural Load Capacity

- Fire Resistance and Safety Considerations

- Acoustics and MDF Thickness

- 10 Important Tips for Choosing the Right MDF Thickness

- Conclusion

- Frequently Asked Questions (FAQs)

Why MDF Thickness Matters

MDF may look uniform, but not all sheets are created equal. A sheet that is too thin can warp, bend, or fail under pressure. A sheet that is too thick may add unnecessary weight, cost, or restrict design flexibility. Precision is everything in fabrication, and thickness selection is at the heart of it.

For example, when Medalco worked on a boutique retail store’s display shelving, the client initially requested thin MDF panels for a minimalist appearance. After analysis, our team recommended a slightly thicker option. The result was shelving that looked sleek but could also handle heavy merchandise without sagging.

The key takeaway: MDF thickness is more than just a measurement. It is a design decision that shapes performance, beauty, and practicality.

Tip 1: Match Thickness to Function

Ask yourself: what will this panel need to do? A closet drawer bottom has very different needs compared to a decorative wall panel.

- Closets and shelving: Require stronger thickness, often 18mm or more, to handle load.

- Wall panels or decorative trims: Can work with thinner MDF, usually 6–12mm, since they aren’t load-bearing.

- Cabinet doors: Often between 15–18mm, balancing strength with maneuverability.

At Medalco, our CNC and waterjet systems allow us to fine-tune cut-outs regardless of thickness, but the project’s purpose always leads the recommendation.

Tip 2: Consider Long-Term Durability

Thicker MDF generally withstands stress better over time. For furniture expected to last years, thicker boards are worth the investment.

A real-world example: Medalco fabricated a luxury wardrobe system with sliding doors in San Jose. The client wanted ultra-thin panels to keep the doors lightweight. Instead, we used reinforced 18mm MDF paired with custom waterjet-cut handles in stone. The result: smooth operation, resilience, and a design that combined wood and stone without compromising durability.

Tip 3: Balance Aesthetics with Practicality

Thin MDF looks sleek but can be fragile. Thick MDF feels substantial but may appear bulky. Finding balance is key.

For instance, a modern floating shelf may look elegant with 12mm MDF, but it risks bowing if too much weight is added. The Medalco team often layers MDF or combines it with metal brackets to achieve both beauty and strength.

Tip 4: Think About Edge Banding

Edge banding hides raw MDF edges and adds style. However, the thickness of MDF affects how the banding adheres and performs.

- Thin boards: More prone to chipping during banding.

- Thicker boards: Provide stronger bonding and allow for creative beveled or rounded edges.

At Medalco, our edge banding services are enhanced with CNC-guided precision, ensuring smooth finishes regardless of the thickness chosen.

Tip 5: Adapt Thickness to Material Combinations

MDF rarely exists alone in high-end projects. It often pairs with stone, metal, wood, or glass. Thickness must complement these materials.

- Stone inlays: Require thicker MDF (18–25mm) to provide enough depth and stability.

- Glass overlays: Work best with medium thickness MDF to reduce weight but maintain rigidity.

- Metal frames: Can support thinner MDF panels for a lightweight, modern look.

Medalco excels at combining materials using waterjet cutting. For example, when designing a custom closet with stone-accented drawer fronts, we used 20mm MDF to balance the heavy stone face, ensuring both durability and beauty.

Tip 6: Account for Waterjet and CNC Cutting Behavior

Different materials react uniquely to waterjet and CNC machining. MDF generally handles both well, but thickness influences cutting precision.

- Thin MDF: Cuts faster but can chip more easily.

- Thicker MDF: Requires slower cutting but yields smoother edges and deeper design options.

This is why Medalco often recommends medium to thick MDF when clients want detailed CNC patterns, as it provides depth for engraving and a more polished final result.

Tip 7: Factor in Installation Method

How the MDF will be mounted matters. Wall-mounted panels require different strength than floor-standing cabinetry.

- Wall-mounted designs: Often better with medium thickness (12–18mm) to avoid excess weight.

- Freestanding furniture: Benefits from thicker MDF for sturdiness.

For one San Jose office project, Medalco used 16mm MDF panels for wall-mounted acoustic boards. The panels were lightweight yet strong enough to stay flat and stable over time.

Tip 8: Be Aware of Environmental Conditions

Moisture and humidity can impact MDF. While moisture-resistant MDF exists, thickness still plays a role.

- Thin boards: More vulnerable to warping in damp spaces.

- Thicker boards: Offer more resistance but must still be sealed.

Medalco often applies protective coatings during fabrication, especially for closets or cabinetry intended for kitchens and bathrooms.

Tip 9: Calculate Cost Efficiency

Thicker MDF costs more, but it might save money in the long run by reducing replacements or repairs. Still, overbuilding can inflate budgets unnecessarily.

Our team helps clients balance cost by recommending the “sweet spot” thickness. For example, in a commercial display case project, 15mm MDF proved both cost-effective and strong enough to endure heavy daily use.

Tip 10: Test Samples Before Committing

Whenever possible, test MDF samples before committing to large-scale fabrication. This allows you to check weight, feel, and compatibility with finishes.

Medalco provides clients with mockups and prototypes, letting them physically see and touch different MDF thicknesses before production. This eliminates guesswork and ensures satisfaction with the final product.

Real-World Applications and Material Insights

How Medalco Brings MDF to Life

At Medalco, MDF is never just a sheet of engineered wood. It is a canvas that we combine with stone, glass, and metal through advanced CNC and waterjet cutting techniques. Our work shows that choosing the right MDF thickness directly shapes how these materials interact in the final design.

One client in San Jose approached us to design a luxury kitchen with a stone island featuring hidden MDF support. By using 25mm MDF panels, we created an invisible frame strong enough to hold natural stone countertops. The thicker MDF served as a backbone, while precise CNC cuts allowed for seamless integration with stone and steel brackets.

MDF and Stone: The Power Duo

Stone, whether marble, granite, or quartz, is beautiful but heavy. Pairing it with MDF requires careful thickness selection.

- Thin MDF (≤12mm): Not strong enough for stone overlays, risks bowing.

- Medium MDF (15–18mm): Adequate for light stone veneer panels.

- Thick MDF (20–25mm): Best for structural support under countertops or stone inlays.

At Medalco, waterjet cutting enables us to cut stone with precision and then match those cuts with MDF bases of exact thickness. This fusion creates decorative wall panels, custom fireplaces, and even furniture that combine strength with artistic elegance.

Authoritative Resource: Architectural Digest on stone and wood design explores how mixing natural and engineered materials elevates interiors.

MDF and Glass: Lightness Meets Support

Glass brings transparency and light into cabinetry and furniture. MDF, when paired at the right thickness, provides the stability glass needs without overshadowing its delicacy.

- 12–15mm MDF: Works well for glass cabinet doors and shelving frames.

- 18mm MDF: Recommended for glass-inlaid panels to prevent warping.

In a Medalco custom project for a boutique display cabinet, 15mm MDF frames were paired with tempered glass. Waterjet precision ensured snug glass placement, while the chosen MDF thickness prevented bending over time.

Authoritative Resource: Glass Magazine highlights how glass and wood composites are shaping modern furniture and displays.

MDF and Metal: Strength with a Modern Edge

Metal pairs beautifully with MDF in modern designs, but thickness plays a crucial role in achieving balance.

- Thin MDF (≤12mm): Works with steel or aluminum frames for a lightweight, industrial look.

- Medium MDF (15–18mm): Ideal for decorative wall panels with metallic overlays.

- Thick MDF (20mm+): Supports heavy-duty metal inserts or exposed hardware.

Medalco’s edge banding and CNC machining make MDF-metal designs seamless. In one project, we combined 18mm MDF with brushed aluminum edges for a tech-inspired office reception desk. The result was durable, sleek, and instantly memorable.

Authoritative Resource: Dezeen regularly covers innovative MDF-metal integrations in furniture and architectural interiors.

MDF and Wood: Harmony in Layers

Although MDF is an engineered wood product, it complements natural woods beautifully. Many high-end projects layer MDF with walnut, oak, or maple veneers.

- Thin MDF (6–12mm): Great as a base for veneers or layered wood panels.

- Medium MDF (15–18mm): Works well for veneered cabinet doors.

- Thick MDF (20mm+): Allows deeper routed details before veneering.

For a residential project, Medalco created an accent wall with oak veneer over 18mm MDF panels. CNC grooves added depth, while the MDF provided stability to prevent cracking that solid oak alone might suffer.

Authoritative Resource: Woodworking Network explains why MDF is often chosen as a substrate for natural wood veneers in cabinetry and furniture.

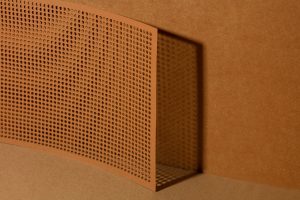

MDF in Decorative Waterjet Art Panels

One of Medalco’s specialties is decorative art panels made from MDF, cut with waterjet for intricate geometric or floral patterns. Thickness dramatically changes the visual effect:

- Thin MDF (6–9mm): Produces lightweight panels ideal for wall décor or ceilings.

- Medium MDF (12–15mm): Offers depth for more pronounced patterns.

- Thick MDF (18–25mm): Creates dramatic, layered panels that can be backlit or combined with stone.

For a corporate lobby, Medalco produced 20mm MDF panels with CNC-carved patterns layered against LED backlighting. The effect was architectural, transforming plain MDF into a premium design element.

Authoritative Resource: ArchDaily showcases global architectural trends where MDF panels play a major role in decorative design.

Case Study: Retail Space Transformation

A retail clothing store in downtown San Jose needed durable but stylish wall and shelving solutions. Initially, the owners wanted to use plywood to reduce costs. Medalco advised 18mm MDF with a matte laminate finish instead.

Why? MDF provided smoother edges for CNC-cut branding logos, and the chosen thickness gave the shelves durability without excessive weight. The outcome was a modern, functional retail environment where every detail, from signage to shelving, was cut with precision.

Case Study: Residential Custom Closet

A homeowner wanted a high-end walk-in closet with glass doors, stone drawer fronts, and wood veneer accents. The design called for balancing multiple materials. Medalco used:

- 20mm MDF for the structural panels.

- 18mm MDF veneered with walnut for the cabinetry.

- 15mm MDF for glass-inlaid door frames.

The result was a luxurious closet system where MDF thickness choices directly impacted functionality, stability, and elegance.

Engineering Precision in MDF Thickness

Precision is everything in fabrication. At Medalco, we often remind clients that choosing MDF thickness is not just about aesthetics, it’s about engineering. A millimeter too thin can mean warping or structural failure. A millimeter too thick can mean excess weight or difficulty integrating with glass, stone, or hardware.

Our CNC machines allow us to work within tolerances as fine as 0.1mm. This level of accuracy ensures that cabinet doors align perfectly, shelves sit flush, and decorative panels interlock seamlessly. Whether it’s a 12mm MDF panel for a glass-inlaid cabinet or a 25mm base for a stone overlay, CNC precision ensures no room for error.

Example: For a San Jose office renovation, Medalco installed MDF partitions with integrated acoustic panels. Using 18mm MDF cut with CNC, we maintained consistent thickness across 40+ partitions, achieving exact fit for soundproofing without gaps.

Sustainability and Responsible MDF Choices

Today’s clients are increasingly concerned with sustainability. MDF, as an engineered wood product, already helps reduce waste by using recycled wood fibers. But thickness also plays a role in environmental impact.

- Thinner MDF (≤12mm): Uses fewer raw fibers, lighter shipping weight, but limited strength.

- Medium MDF (15–18mm): Balanced option for furniture and cabinetry.

- Thicker MDF (20mm+): Requires more material but often lasts longer, reducing replacement waste.

At Medalco, we guide clients toward FSC-certified MDF and water-based adhesives that minimize harmful emissions. We also optimize cutting layouts with CNC and waterjet technology, ensuring minimal offcuts and waste.

Authoritative Resource: Forest Stewardship Council (FSC) provides global guidelines for sustainable wood sourcing, including MDF production.

Fabrication Techniques that Maximize MDF Performance

1- Edge Banding with Precision

Edge banding protects MDF edges from moisture and gives a polished finish. With CNC guidance, Medalco applies edge banding that matches MDF thickness exactly, preventing peeling and ensuring long-lasting durability.

2- Lamination and Veneering

The right MDF thickness enhances the bond between laminate or veneer and the substrate. For example, 18mm MDF is ideal for high-pressure laminates used in kitchen cabinetry, while 12mm MDF works well for lightweight decorative laminates.

3- Waterjet for Complex Designs

Although MDF is softer than stone or metal, waterjet cutting is often used for hybrid panels where MDF is combined with harder materials. By carefully controlling pressure, Medalco achieves clean cuts without swelling or tearing the MDF surface.

Example: For a hospitality project, Medalco combined 16mm MDF with brass inlays cut using waterjet. The result was a stunning lobby wall panel that looked hand-crafted but was engineered with modern precision.

MDF Thickness and Structural Load Capacity

Thickness directly affects how much weight MDF can support. Medalco engineers test designs against expected loads before fabrication.

- 12mm MDF shelves: Suitable for light items like décor or books up to 5kg.

- 18mm MDF shelves: Can hold moderate loads like kitchenware or electronics up to 15kg.

- 25mm MDF shelves: Ideal for heavy-duty storage or retail displays holding 25kg or more.

Example: In a luxury retail boutique, Medalco used 25mm MDF shelving with veneer finishes to safely display heavy stone sculptures.

Fire Resistance and Safety Considerations

Another overlooked factor is fire resistance. Thicker MDF panels naturally resist flames longer than thinner panels, and fire-rated MDF is available for projects that require higher safety standards. Medalco often recommends 18mm or thicker fire-rated MDF for commercial spaces such as hotels or offices.

Authoritative Resource: UL Solutions provides guidelines on MDF fire resistance ratings for architectural applications.

Acoustics and MDF Thickness

MDF is also widely used in acoustic paneling. Thicker panels absorb more sound, making them ideal for theaters, studios, or offices.

- 12mm MDF: Limited acoustic performance, best for decorative use.

- 18mm MDF: Provides noticeable noise reduction.

- 25mm MDF: Excellent for soundproofing applications when combined with acoustic foam.

Example: Medalco produced custom 20mm MDF acoustic panels with geometric CNC cuts for a recording studio. The thickness not only reduced sound reflection but also gave the space a modern, artistic identity.

10 Important Tips for Choosing the Right MDF Thickness

1- Match Thickness to Application

Use 12mm MDF for lightweight wall panels, 18mm for cabinetry, and 25mm for heavy-duty shelves. Medalco helps clients analyze usage before selecting.

2- Consider Structural Load

Estimate the weight the MDF will carry. Undersized panels risk sagging. Medalco engineers run load simulations to ensure safety.

3- Balance Aesthetics with Function

Thicker MDF gives a bold, luxurious appearance, while thinner panels look sleek and minimal. Medalco integrates both depending on design intent.

4- Account for Edge Banding

Edge banding must match MDF thickness. A mismatch can lead to peeling. CNC precision at Medalco eliminates this risk.

5- Evaluate Moisture Exposure

Kitchens, bathrooms, or laundry rooms require thicker MDF or special moisture-resistant grades.

6- Check for Fire Resistance Needs

Public and commercial spaces often require fire-rated MDF. Medalco sources certified materials that meet safety codes.

7- Optimize for Finishing Techniques

Veneering and lamination bond best to medium-thickness MDF. Medalco uses 18mm as the golden balance for luxury cabinets.

8- Factor in Weight and Handling

Heavier MDF is harder to transport and install. Medalco uses CNC layouts to optimize material usage and minimize waste.

9- Incorporate Hybrid Materials

If combining MDF with stone, glass, or metal, adjust thickness accordingly. Medalco’s waterjet cutting allows seamless integration of multiple materials.

10- Think Long-Term Durability

Invest in thickness that supports not only today’s design but also future use. Medalco emphasizes longevity, especially in high-traffic spaces.

Conclusion

Choosing the right MDF thickness is both an art and a science. From structural load and moisture resistance to aesthetics and sustainability, every millimeter matters. Medalco’s expertise in CNC machining, waterjet cutting, and custom fabrication ensures that each project gets a tailored solution with precision and durability at its core.

Whether you are designing a luxury closet, a modern kitchen, or a commercial interior, the right MDF thickness defines both the beauty and strength of the final product.

Frequently Asked Questions (FAQs)

| 1. What is the most common MDF thickness for cabinets? A1: The most common is 18mm, offering an ideal balance between durability and workability. Medalco uses this thickness for most custom cabinetry. |

| 2. Can thinner MDF save costs without compromising quality? A2: Yes, but only in low-stress applications like wall panels. For load-bearing designs, thinner MDF risks warping or sagging. |

| 3. Is thicker MDF always better? A3: Not necessarily. While thicker MDF is stronger, it’s also heavier and more costly. The right choice depends on the specific project. |

| 4. How does moisture affect MDF thickness selection? A4: In humid environments, moisture-resistant MDF in 18–25mm thickness is recommended. Medalco sources materials built for these conditions. |

| 5.Can MDF be combined with stone or glass? A5: Yes, with proper engineering. Medalco often combines MDF with waterjet-cut stone or glass for hybrid decorative panels. |

| 6. What thickness is best for shelving? A6: 18mm for light to medium loads and 25mm for heavy-duty storage. Medalco tests load capacity before fabrication. |

| 7. Is fire-rated MDF available in multiple thicknesses? A7: Yes, ranging from 12mm to 25mm. Medalco typically recommends 18mm+ for safety in commercial applications. |

| 8. Does CNC cutting improve MDF performance? A8: Absolutely. CNC ensures perfect edges, consistent dimensions, and accurate fitting, which enhances both strength and appearance. |

| 9. What thickness is ideal for acoustic panels? A9: 20–25mm provides the best sound absorption, especially in studios and theaters. Medalco has produced multiple acoustic solutions using MDF. |

| 10. How can I be sure I’m choosing the right MDF thickness? A10: Partner with a specialist. Medalco evaluates your project’s function, style, and environment to recommend the best thickness for lasting performance. |

Ready to bring your design vision to life with the perfect MDF solution? Medalco is here to guide you from material selection to final installation. With expertise in CNC machining, waterjet cutting, and custom fabrication, we deliver precision-crafted solutions that balance beauty, strength, and sustainability.

Contact Medalco today to discuss your project and discover how the right MDF thickness can elevate your design.

Trusted External Resources

- Insights on trends and best practices in custom cabinetry and wood fabrication.

- Leading source for stone cutting and finishing technologies.

- Covers innovations in metal cutting and forming.

- Authority on glass processing and architectural integration.

- Technical resource on CNC, waterjet, and other precision fabrication tools.