10 Major Benefits of CNC for Interior Design

Introduction

The world of interior design is no longer defined only by the creativity of the designer or the skill of the craftsman. Today, technology is equally influential, especially CNC (Computer Numerical Control) machining. From shaping intricate wood panels to cutting stone with flawless precision, CNC has become the cornerstone of modern fabrication.

At Medalco, we have seen firsthand how CNC transforms ideas into tangible works of art. By combining CNC with advanced waterjet cutting and traditional craftsmanship, our team delivers interiors that are functional, sustainable, and breathtaking. This article explores ten major benefits of CNC for interior design, supported by real-world case studies, material insights, and practical applications.

Table of contents

- 10 Major Benefits of CNC for Interior Design

- Introduction

- 1. Unmatched Precision in Design Execution

- 2. Customization Without Limits

- 3. Time Efficiency and Faster Project Delivery

- 4. Complex Geometries and Creative Freedom

- 5. Material Versatility

- 6. Consistency Across Multiple Units

- 7. Cost-Effectiveness Through Reduced Waste

- 8. Sustainability and Eco-Friendly Practices

- 7- Birch: Affordable and Sustainable Utility

- 9. Faster Installation with Better Fit

- 10. Blending Technology with Artistry

- CNC and Material Versatility

- Medalco Project Highlights

- 10 Frequently Asked Questions (With Answers)

1. Unmatched Precision in Design Execution

One of the strongest advantages of CNC in interior design is precision. Unlike manual cutting or fabrication, CNC machines translate digital models into exact cuts with tolerances measured in fractions of a millimeter.

Example from Medalco:

Recently, a client requested a custom feature wall made of walnut panels with flowing, organic curves. Using CNC technology, our team translated a digital 3D sketch into a real-world installation where every curve aligned perfectly with the design vision.

Materials and Behavior:

- Wood: CNC routers excel at carving complex joinery and intricate shapes without splintering.

- Stone: When combined with waterjet cutting, CNC achieves flawless edges in marble, granite, and quartz.

- Glass and Metal: CNC ensures uniform cuts without stress fractures.

Precision is not just about aesthetics. It saves material, reduces waste, and makes installation smoother.

2. Customization Without Limits

CNC allows designers to create customized elements that would be impossible or impractical by hand. Whether it is a one-of-a-kind cabinet door pattern, a carved stone countertop edge, or a branded metal inlay, CNC makes personalization accessible at scale.

Case Study:

For a boutique hotel in San Jose, Medalco fabricated custom closet doors with CNC-carved motifs inspired by local art. Each room had its own variation, proving that CNC can deliver individuality even in multi-unit projects.

Why This Matters:

CNC enables truly personalized interiors, from bespoke furniture to tailored wall panels.

Interior design is moving away from cookie-cutter solutions.

3. Time Efficiency and Faster Project Delivery

In the fast-paced construction and design industry, time is as valuable as creativity. CNC machines significantly reduce the time required for fabrication by automating repetitive and detailed tasks.

Example:

What might take days for a craftsman to carve manually can be achieved in hours with CNC, without sacrificing accuracy. Medalco uses CNC not just to speed up production but to synchronize timelines with waterjet cutting and edge banding for faster, more efficient delivery.

Materials Impact:

- Stone: CNC waterjet cutting avoids tool wear, which traditionally slows down manual stonework.

- Wood: Automated cutting and joinery reduces manual labor hours.

- Metal/Glass: CNC reduces polishing time by delivering cleaner cuts.

4. Complex Geometries and Creative Freedom

CNC opens the door to geometries that traditional fabrication cannot achieve. Curved, interlocking, or tessellated patterns are executed with ease, enabling designers to push creative boundaries.

Medalco in Action:

In a recent residential project, our team created a geometric stone wall with repeating triangular patterns, all precisely cut via CNC waterjet. The client described it as “functional sculpture.”

Why It Matters for Interior Design:

- CNC gives designers the freedom to think beyond straight lines and flat planes.

- Complex geometries add artistic depth, architectural value, and client appeal.

5. Material Versatility

One of CNC’s strongest features is its ability to work with multiple materials. Designers are no longer limited to wood or stone, they can combine various textures and finishes in one project.

How Materials Respond:

- Wood: Softwoods and hardwoods cut cleanly, ideal for cabinets and furniture.

- Stone: Marble, granite, and engineered quartz respond beautifully to CNC waterjet cutting.

- Glass: Intricate shapes without cracking.

- Metal: Precise inlays and decorative trims are achievable.

Medalco Example:

For a modern kitchen project, Medalco integrated CNC-carved wooden cabinet doors with waterjet-cut stone countertops and brushed steel accents. The result was a seamless blend of materials, elevating both durability and design.

6. Consistency Across Multiple Units

For large-scale projects like hotels, office complexes, or multi-unit residences, consistency is everything. A slight deviation in one cabinet door or wall panel can disrupt the harmony of an entire space. CNC ensures that every piece fabricated is an exact replica of the digital model.

Medalco Case Example:

A commercial office renovation in San Jose required 80 identical walnut veneer panels with inlaid stone strips. With CNC precision, Medalco produced all panels with perfect consistency. The waterjet-cut stone inserts fit seamlessly into every slot without manual adjustments.

Why It Matters:

- Avoids inconsistencies caused by human error.

- Guarantees a unified aesthetic across multiple rooms or floors.

- Enhances client satisfaction, especially in high-end or luxury projects.

7. Cost-Effectiveness Through Reduced Waste

While CNC technology is advanced, it is also surprisingly cost-effective in the long run. Manual fabrication often leads to waste from measurement errors or trial-and-error processes. CNC machines optimize material usage by following digital layouts with surgical precision.

Material Impact:

- Many suppliers now focus on replanting walnut trees.

- FSC-certified walnut ensures eco-friendly practices.

- Durability makes it a long-term investment.

Example from Medalco:

In a custom closet project using high-end mahogany, CNC helped us maximize material yield. By nesting digital patterns efficiently, we reduced waste by nearly 18 percent compared to manual methods. That saving was passed directly to the client.

Why Clients Value This:

- Lower costs.

- Eco-friendly fabrication (less waste sent to landfills).

- Faster project timelines.

8. Sustainability and Eco-Friendly Practices

A recent project in Palo Alto showcases how sustainable wood can transform interiors. The client requested a modern kitchen with eco-friendly materials. Medalco proposed a combination of FSC-certified oak for cabinetry, bamboo for shelving, and walnut for the island base.

Key highlights:

- Waterjet precision: Stone countertops were cut with our waterjet machine, ensuring minimal waste.

- CNC optimization: Cabinet parts were nested digitally to reduce material loss.

- Eco-finishes: All woods were treated with water-based, low-VOC sealants.

The result was a kitchen that looked luxurious, performed flawlessly, and aligned with the client’s environmental values.

7- Birch: Affordable and Sustainable Utility

CNC technology aligns with the global movement toward sustainable design. By optimizing cuts and reducing material waste, it contributes directly to eco-friendly practices in fabrication.

Sustainable Advantages of CNC:

- Precise cutting reduces energy use during finishing processes.

- Less wasted material means fewer natural resources consumed.

- Digital design files minimize the need for physical prototypes.

At Medalco, sustainability is central to our ethos. For example, we recently used CNC waterjet cutting to fabricate stone wall panels for a client’s eco-friendly home in Palo Alto. The precision cuts allowed us to repurpose offcuts as decorative side tables and smaller design accents.

External Insight:

The United States Green Building Council (USGBC) highlights material efficiency and waste reduction as core principles of sustainable building. CNC directly supports these standards.

9. Faster Installation with Better Fit

When fabrication is precise, installation becomes much smoother. Poorly cut pieces require adjustments onsite, leading to delays and potential compromise of the final design. CNC ensures parts fit together like puzzle pieces.

Medalco Example:

A luxury kitchen in Los Gatos featured CNC-cut stone countertops paired with wood cabinetry. Because every cutout for sinks and appliances was digitally templated and CNC-executed, installation took two days less than originally scheduled.

Why This Matters for Clients:

- Less disruption in their homes or businesses.

- Faster project completion leads to quicker occupancy.

- Reduced labor costs on installation.

Tip: CNC precision also reduces the need for filler strips, sanding, or patching, common in manual fabrication.

10. Blending Technology with Artistry

Perhaps the most exciting aspect of CNC is how it bridges the gap between technology and artistry. While machines handle precision, artistry comes alive in design, finishing, and material pairing.

How Medalco Does It:

- CNC and waterjet deliver the framework with accuracy.

- Our skilled artisans finish edges, apply stains, or integrate hand-carved details.

- The result is a product that embodies both technical perfection and artistic soul.

Case Study:

In a modern interior renovation, Medalco designed a feature staircase with CNC-cut wooden steps and waterjet-cut metal side panels engraved with organic leaf patterns. The combination of CNC precision and artistic vision transformed a functional staircase into a centerpiece of the home.

Why It Resonates:

Clients increasingly want interiors that feel unique, human, and artistic. CNC empowers artisans to focus on creativity instead of repetitive manual labor, delivering interiors that truly inspire.

CNC and Material Versatility

One of the most transformative aspects of CNC in interior design is its ability to work with a wide variety of materials. Unlike traditional hand tools that may be limited in scope, CNC machines are adaptable, ensuring each cut is precise regardless of density, hardness, or brittleness.

At Medalco, we often pair CNC machining with waterjet cutting to expand design possibilities further. This hybrid approach allows us to transition seamlessly between wood, stone, metal, and even glass, all within the same project.

Let’s explore how CNC interacts with these core materials:

1- Wood

Wood remains the foundation of most interior design projects, whether for cabinetry, paneling, or furniture. CNC excels at handling both solid woods and engineered boards like MDF, plywood, or veneer-laminated panels.

- Applications: Custom cabinetry, intricate engravings, furniture joints.

- Advantages: Cleaner cuts, accurate joinery, minimal splintering.

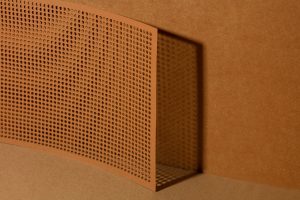

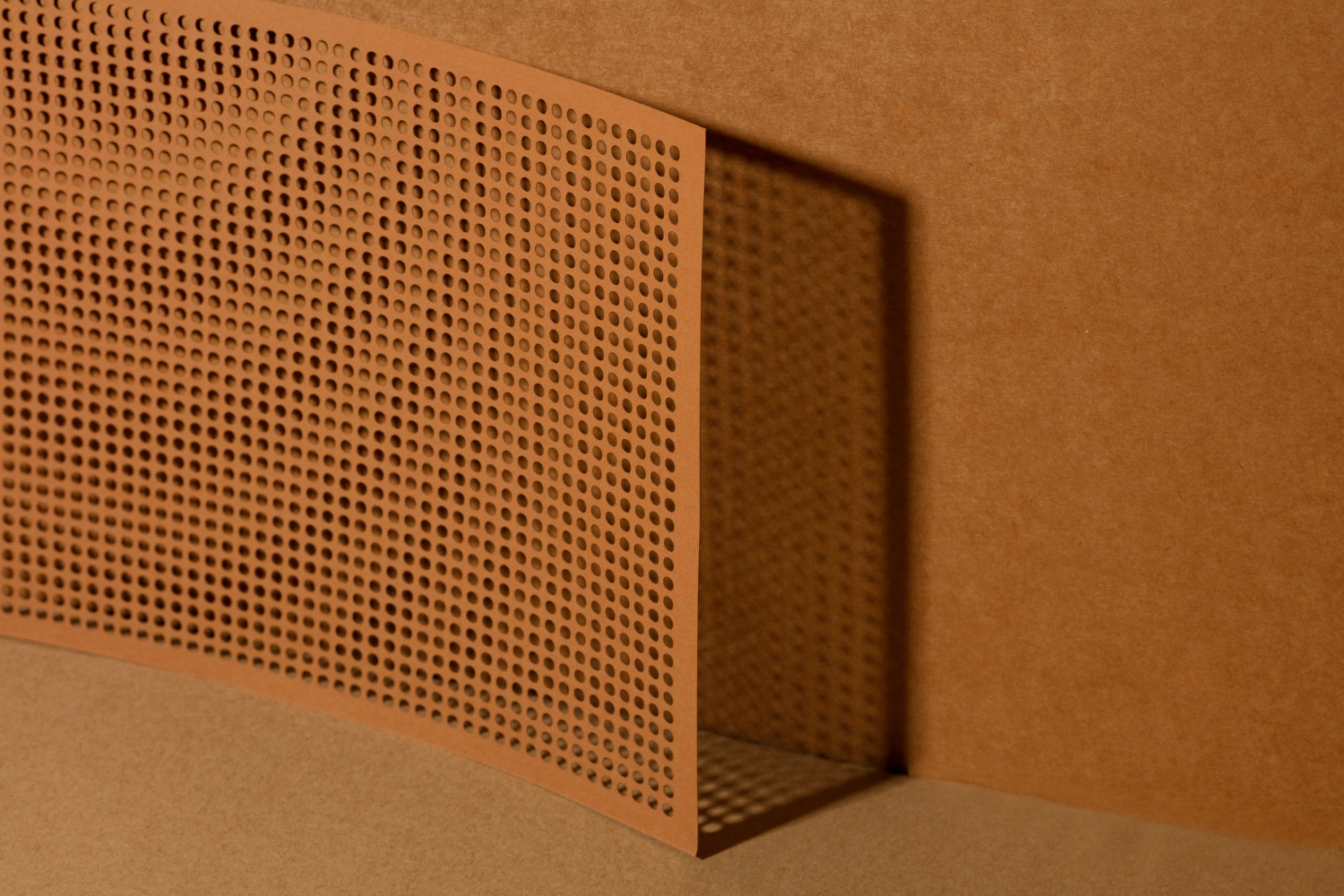

- Medalco Example: For a boutique kitchen in Mountain View, CNC was used to mill walnut cabinet doors with a geometric lattice pattern. The precision ensured all doors aligned perfectly when closed, creating a seamless effect.

2- Stone

Stone is notoriously challenging to work with, especially for detailed designs. Medalco frequently combines CNC routing with waterjet cutting to achieve results that are both structural and artistic.

- Applications: Countertops, decorative wall panels, flooring inlays.

- Advantages: Precision cutouts for sinks, faucets, and integrated lighting.

- Medalco Example: In a Los Altos luxury bathroom, CNC and waterjet technology were used to craft a marble vanity top with delicate inlays of black granite. The accuracy eliminated the need for manual adjustments during installation.

3- Metal

Metals such as aluminum, brass, and stainless steel add a sleek, modern touch to interiors. CNC machining allows for millimeter-perfect fabrication of both structural and decorative components.

- Applications: Stair railings, decorative trims, furniture frames.

- Advantages: Uniformity across parts, compatibility with welding or modular assembly.

- Medalco Example: Medalco fabricated brushed brass screens for a high-end retail store in San Jose. The CNC machine handled repetitive geometric cutouts with absolute consistency, making the installation flawless.

4- Glass

Glass, though fragile, is increasingly being used for interior partitions, tabletops, and artistic installations. CNC combined with waterjet is ideal for creating customized shapes, cutouts, or etched designs.

- Applications: Shower enclosures, tabletops, illuminated wall features.

- Advantages: Smooth, chip-free edges and complex patterns.

- Medalco Example: In a Palo Alto residence, Medalco fabricated etched glass panels with organic wave patterns for a staircase railing. CNC precision ensured each panel matched perfectly from floor to floor.

5- Hybrid Materials

Today’s interiors often mix materials for a multilayered aesthetic. CNC makes it possible to integrate wood, stone, and metal into cohesive designs.

- Medalco Example: In one of our signature projects, a living room wall feature combined CNC-milled oak panels, waterjet-cut stone tiles, and brushed aluminum inlays. This combination created a focal point that was both artistic and modern.

Medalco Project Highlights

The Boutique Hotel Lobby, San Jose

For this project, Medalco used CNC to fabricate decorative wall panels in maple veneer, complemented by waterjet-cut stone accents. Each panel carried a subtle floral motif, designed digitally and then executed flawlessly. Guests entering the lobby are immediately struck by the harmony of technology and artistry.

Luxury Kitchen Renovation, Los Gatos

Medalco created CNC-cut cabinetry, with stone countertops precision-fitted using waterjet technology. The result was a kitchen where wood and stone worked together seamlessly, with no visible seams or awkward joints. This project exemplifies how CNC streamlines both design vision and practical execution.

Corporate Office Panels, San Francisco

A large tech office required consistent wall and ceiling panels across multiple floors. Medalco employed CNC to fabricate lightweight MDF panels laminated in natural oak veneer. Because of CNC’s precision, every panel was uniform, and installation times were cut in half compared to manual fabrication

Residential Artistic Staircase, Palo Alto

This project showcased CNC’s role in turning a staircase into a functional sculpture. Medalco fabricated CNC-milled wood steps, combined with laser-like waterjet-cut metal side panels. The result was a staircase that doubled as a statement piece, blending strength with artistry.

CNC’s Role in Architectural Innovation

CNC is not only about interior design elements but also about reshaping architectural possibilities. Architects and designers now rely on CNC to create structural features that would have been nearly impossible with manual methods.

- Parametric Designs: CNC enables organic and flowing forms once limited to concept drawings.

- Precision Joinery: Complex connections can now be fabricated digitally, allowing for stronger and more elegant structures.

- Integration with BIM: CNC files often stem directly from architectural software, ensuring a seamless transition from design to fabrication.

External Resource: The American Institute of Architects (AIA) has emphasized how digital fabrication technologies like CNC are redefining the design-to-build process in modern architecture.

Conclusion

CNC technology is not just a tool. It is a revolution in the way interior design and fabrication are approached. From wood cabinetry to stone countertops, from glass panels to hybrid materials, CNC opens possibilities that were once limited by hand tools and time-consuming craftsmanship.

At Medalco, we have seen firsthand how CNC, when combined with waterjet cutting and custom fabrication, transforms both small residential projects and large-scale architectural ventures. Our clients consistently appreciate the precision, efficiency, and artistry that CNC brings into their homes, offices, and commercial spaces.

Whether you are an architect designing a futuristic office, a homeowner upgrading a kitchen, or a developer looking to bring sustainability and accuracy into your projects, CNC has benefits that extend far beyond simple cutting. It ensures design intent translates into flawless execution.

10 Frequently Asked Questions (With Answers)

1. What is CNC in interior design?

CNC, or computer numerical control, refers to machines that follow digital design files to cut, shape, or engrave materials with precision. In interior design, CNC is used for cabinetry, furniture, wall panels, and custom architectural features.

2. How does CNC improve precision compared to manual methods?

CNC machines follow exact digital instructions, reducing human error. This results in consistent accuracy across multiple components, ensuring seamless installation.

3. Which materials can CNC machines handle for interiors?

CNC works with wood, stone, metal, and glass. At Medalco, we often combine CNC with waterjet cutting to expand possibilities for hybrid or intricate designs.

4. Is CNC useful only for large projects?

No. CNC is equally valuable for small projects like a custom closet as it is for large-scale office or hospitality interiors. The scalability of CNC makes it highly versatile.

5. Can CNC help with eco-friendly design?

Yes. CNC reduces waste by optimizing cuts and ensuring maximum material efficiency. It also enables the use of sustainable woods and composites in interiors.

6. How does Medalco use CNC in its projects?

Medalco integrates CNC into cabinetry, stonework, and decorative panels. By combining CNC with waterjet, we create designs that balance strength, elegance, and functionality.

7. Is CNC cost-effective for homeowners?

While CNC might have higher initial setup costs, it saves money long term by reducing material waste, lowering labor costs, and ensuring faster installations.

8. Can CNC create artistic designs, or is it only functional?

CNC is both functional and artistic. From organic patterns in wood panels to intricate inlays in stone floors, CNC allows designers to bring creative visions to life.

9. Does CNC require special design software?

Yes. Designers typically use CAD (computer-aided design) software to create files for CNC machines. Medalco’s team can work directly with architects or generate designs in-house.

10. How do I get started with a CNC-based project at Medalco?

It’s simple. Contact Medalco with your design ideas or plans. Our team will guide you through design, material selection, and fabrication to bring your project to reality.

Are you ready to elevate your interiors with CNC precision and Medalco’s craftsmanship? Whether you need custom cabinetry, stonework, or artistic panels, our team is here to make your vision a reality.

Contact Medalco today to discuss your next project and discover how CNC and waterjet technology can transform your interior design into timeless artistry.

Trusted External Resources

- Insights on trends and best practices in custom cabinetry and wood fabrication.

- Leading source for stone cutting and finishing technologies.

- Covers innovations in metal cutting and forming.

- Authority on glass processing and architectural integration.

- Technical resource on CNC, waterjet, and other precision fabrication tools.