10 Responses to How We Use Waterjet to Create Custom Fireplace Designs

Introduction: The Magic of Custom Fireplaces with Waterjet Cutting

There’s something timeless about a beautiful fireplace. It’s more than just a place to stay warm it’s a centerpiece, a conversation starter, a statement. And when it’s custom-designed from natural stone, it becomes art. At Medalco, we bring these designs to life using precision waterjet technology. People often ask how we do it and honestly, we love that question. So here are 10 ways we use waterjet cutting to create stunning, one-of-a-kind fireplaces that combine form and function.

What Is Waterjet Cutting and Why Is It Perfect for Fireplaces?

Think of waterjet cutting as carving with water at 60,000 psi. It’s a cold, ultra-precise method of cutting through stone, metal, and other materials without using heat. That’s a big deal when working with natural materials that crack or discolor under high temperatures.

The Basics of Waterjet Cutting

Waterjet cutting uses a narrow stream of high-pressure water, sometimes mixed with abrasive garnet, to slice through even the hardest stone. It’s clean, accurate, and incredibly powerful kind of like using a laser beam made of water.

Cold Cutting Means No Heat Damage

Unlike laser or torch cutting, waterjets don’t produce heat, which is crucial when working with natural stone. No burning, no discoloration, no stress fractures just clean, cool cuts that preserve the beauty of every slab.

Designing a Custom Fireplace: Where Creativity Begins

Every great design starts with a great idea. We sit down with homeowners, designers, and builders to understand their vision. Whether it’s a rustic vibe, a modern statement, or a classic French villa style, we take that inspiration and turn it into something real.

Listening to the Client’s Vision

First, we ask questions. What kind of feeling do you want your fireplace to evoke? What kind of stone do you like? What’s your home’s aesthetic? Once we understand the story, we start sketching ideas.

Turning Sketches into CAD Blueprints

Hand-drawn concepts are turned into precise digital CAD files. These serve as the blueprint for the waterjet machine. Every curve, line, and notch is mapped out ready to be cut with surgical precision.

Response 1

We Use Waterjet to Cut Intricate Patterns in Stone

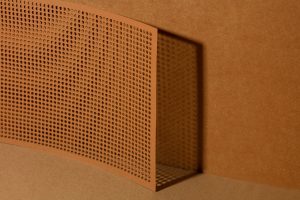

Intricate floral motifs, geometric patterns, delicate scrollwork waterjet makes it all possible. It’s like having a digital sculptor that never misses a detail.

From Classic Scrolls to Modern Geometry

Whether your taste leans toward ornate Victorian scrolls or sleek contemporary patterns, we can bring it to life. Our machines can handle micro-details that would take hours (or days) to carve by hand.

Design Freedom Without Cracks or Chips

Traditional tools risk cracking brittle stone during fine detailing. Waterjet? Not a problem. The non-invasive nature of the process protects the integrity of even delicate slabs.

Response 2

We Work with Multiple Materials

Waterjet technology doesn’t just play nice with stone it excels with it. We regularly cut marble, granite, quartzite, limestone, and more. Each material has its own vibe and story, and waterjet gives us the freedom to work across the board.

Marble, Granite, Limestone, and More

Imagine a white marble surround with intricate floral inlays. Or a matte-finished granite mantel with sharp minimalist lines. No matter your material of choice, waterjet delivers the cuts that elevate your design.

Response 3

We Keep the Details Crisp and Clean

Here’s the thing fireplaces are often focal points, and sloppy work shows. Our waterjet system creates razor-sharp edges and perfect contours, even on the most complex cuts. No grinding, no sanding, just beautifully clean results straight off the machine.

No Grinding, No Heat, Just Precision

Forget scorched edges or choppy finishes. Waterjet delivers a surface so clean you can skip most of the post-processing work. Your stone stays intact, beautiful, and unblemished.

Response 4

We Custom-Cut Mantels, Surrounds, and Hearths

Fireplace designs aren’t one-size-fits-all. We cut everything from floating mantels to decorative surrounds and hearth extensions custom sized to fit your space like a glove.

Creating Perfectly Fitting Stone Components

The beauty of digital precision is in the fit. No guesswork. No uneven gaps. Every piece is shaped exactly to the specs of your fireplace opening or wall design.

Response 5

We Replicate Historical Fireplace Designs

Have a historic home? We love those projects. Using archived photos or original fragments, we recreate ornate stonework with astonishing accuracy. Waterjet makes it possible to bring antique fireplaces back to life down to the last vine scroll or cornice detail.

Waterjet for Restoration and Reproduction

From French chateaux replicas to Victorian revival trims, we cut custom molds and parts that match historical features perfectly. Restoration doesn’t have to mean compromise it can mean perfection.

Response 6

We Incorporate Logos, Monograms, and Decorative Inlays

Want a custom crest in the center of your fireplace? Or initials worked into a stone arch? We can cut ultra-fine monograms and designs for true personalization. It’s like leaving your signature in stone

Personalizing with Art and Identity

From family crests to company logos in commercial spaces, we’ve added artistic touches that make fireplaces memorable. And with waterjet, the precision is so fine, even small fonts or icons are no challenge.

Response 7

We Handle Large Slabs Without Breaking Them

Handling heavy stone is tricky especially when it’s thin or expensive. But waterjet’s non-contact method means we can cut massive slabs without risk of cracking or heat distortion.

Waterjet for Delicate, Large-Scale Stone Cuts

We’ve worked with slabs over 8 feet wide, cutting seamless mantels and full-wall fireplace backdrops. The secret? Precision, patience, and machines built to handle the big stuff without breaking a sweat.

Response 8

We Offer Prototypes Before Final Cuts

Not sure how your design will look in stone? We offer test cuts or scaled prototypes on cheaper materials like foam or scrap stone. You get peace of mind—and the chance to tweak details—before we touch the premium slab.

Saving Time and Cost with Preview Runs

Prototypes help eliminate guesswork. We can spot design flaws early and make adjustments that save you money. It’s just another way we add value beyond the cut.

Response 9

We Reduce Waste and Save Material

Stone is expensive and heavy. We optimize every cut path using smart nesting software that reduces offcuts. Less waste means lower material costs and a greener footprint.

Smart Cutting Paths = Efficient Use of Stone

We digitally arrange pieces like a puzzle to use the slab efficiently. Whether you’re working with marble or onyx, that savings adds up.

Response 10

We Deliver Flawless Results, Every Time

At the end of the day, it’s about trust. Clients count on us to deliver the stone centerpiece of their home. And we don’t take that lightly. With waterjet technology and our skilled team, every cut reflects our commitment to excellence.

Technology + Craftsmanship = Medalco Quality

It’s not just about the machine. It’s the care, the experience, and the eye for detail. That’s what turns raw stone into a showpiece. At Medalco, we bring both brains and artistry to every fireplace we create.

Conclusion: Fireplace the tell a Story

A custom fireplace isn’t just a structure it’s a story carved in stone. Whether it’s the elegance of marble, the richness of granite, or the detail in a family monogram, we use waterjet cutting to turn your ideas into tangible, lasting beauty. At Medalco, our passion lies in crafting fireplaces that feel like home because they were made just for you.

Client Collaboration & Customization Process

How We Translate Vision into Blueprint

At Medalco, we believe a fireplace should reflect your taste, space, and spirit. Our collaboration starts with a conversation not a catalog. We ask questions like, “What mood do you want this room to have?” and “Is this fireplace a centerpiece or a cozy corner?” From there, we draft multiple design concepts.

Once you’re happy with the vision, we create a digital blueprint using software like Rhino, SketchUp, or AutoCAD. This ensures the fireplace proportions, cutouts, and finishes are all pixel-perfect before we even touch the stone.

Collaborating with Architects and Interior Designers

We frequently work hand-in-hand with professionals. Whether it’s interpreting an architect’s blueprint or enhancing a designer’s concept, we ensure our waterjet designs integrate seamlessly into the larger design narrative.

Medalco’s Quality Assurance Process

Inspection, Calibration, and Stress Testing

Our team runs pre-cut calibration tests for each stone slab, checking for internal fissures, mineral inconsistencies, and tension lines. After cutting, each piece undergoes a multi-point inspection for smoothness, dimension, and edge alignment.

Ensuring Long-Term Durability and Fit

We don’t just cut and ship. Our fireplaces are assembled and dry-fitted at our facility before final delivery. This means fewer surprises on-site and guaranteed fit especially for multi-component designs or those involving inlays and engravings.

Design Trends and Fireplace Innovation

The Rise of Minimalist and Geometric Fireplaces

There’s a growing trend toward minimalist fireplace designs with clean lines and strong symmetry. Waterjet is uniquely suited for these forms, delivering sleek, seamless cuts that hand tools struggle with.

Bold Inlays and Personalized Patterns

Clients are increasingly choosing bold inlays—like metallic trims, custom logos, and patterned motifs. With waterjet, we can incorporate brass, copper, or even colored stone into the primary slab with razor-sharp precision.

Fireplace Surrounds, Mantels, and Inlay Options

What’s Possible with Waterjet Precision

From wrap-around stone fireplace surrounds to intricate mantel engravings, waterjet lets us play with depth, layering, and angles like never before. We can taper edges, cut reliefs, and shape transitions between flat and curved surfaces.

Mixing Stone, Metal, and Glass

Medalco’s waterjet allows us to mix materials seamlessly. Imagine a granite surround with brass inlays or a quartzite mantel paired with a glass mosaic centerpiece this isn’t fantasy, it’s fabrication.

FAQs

| 1. Can waterjet cutting be used on delicate materials like onyx or soapstone? Yes, with the right pressure settings, we can safely cut even fragile stones without cracking. |

| 2. How long does it take to design and cut a custom fireplace? Typically 1–2 weeks depending on the complexity, material availability, and approval of the final design. |

| 3. Can I visit your workshop to see the process? Absolutely! We welcome client visits and offer walkthroughs so you can see how your fireplace is being made. |

| 4. Do you only serve clients in San Jose? While we’re based in San Jose, we’ve worked on projects across California and even out-of-state. Shipping and installation support can be arranged. |

| 5. What file types should I send for a custom design? DXF and DWG CAD files are preferred, but we can also work from hand sketches and help convert them to usable formats. |

| 6. Can I mix multiple materials in one fireplace design? Yes! We can waterjet-cut stone, glass, and metal and assemble them in a single, integrated piece |

| 7. What’s the biggest fireplace you’ve fabricated using waterjet? Our largest was a 12-foot-wide travertine unit with backlit onyx inlays, custom-cut in 14 sections and installed seamlessly. |

| 8. Can I preview the design in 3D before fabrication? Definitely. We offer 3D renderings using SketchUp or Rhino so clients can visualize scale and finish. |

| 9. Is there any maintenance needed for waterjet-cut fireplaces? Not more than usual. Our edges are sealed post-cutting, and stone finishes are treated to resist stains and thermal stress. |

| 10. What’s the lead time for a complex, multi-material fireplace? 4 to 6 weeks, depending on design complexity and material sourcing. We keep clients updated every step of the way. |

More About Waterjet Technology and Artistic Applications:

- advantages of waterjet cutting

- waterjet’s material versatility

- waterjet boosting sustainable construction

- waterjet in architectural and decorative stone cutting

- waterjet versus laser, plasma, and mechanical cutting