10 Tools and Equipment We Use in Our Cabinet Installations

Introduction: The Art and Precision Behind Every Cabinet Installation

Cabinet installation is far more than simply fitting boxes into walls. At Medalco, we view every installation as an architectural composition, a harmony between material, space, and human use. Behind the smooth lines, elegant finishes, and precise alignments lies a symphony of tools and equipment engineered for accuracy, efficiency, and aesthetic finesse.

Whether it is a sleek kitchen remodel, a luxury vanity, or custom commercial cabinetry, every Medalco project is backed by a deep respect for materials and craftsmanship. While our waterjet cutting and custom fabrication services are often associated with architectural metalwork, stone inlays, and artistic panels, they also play an integral role in precision cabinetmaking.

In this article, we explore 10 essential tools and pieces of equipment that our teams rely on during cabinet installations. From advanced leveling lasers to diamond-tipped cutting systems, each instrument contributes to the signature quality Medalco is known for.

Table of contents

- 10 Tools and Equipment We Use in Our Cabinet Installations

- Introduction : The Art and Precision Behind Every Cabinet Installation

- 1. Laser Levels: Setting the Foundation of Precision

- 2. Waterjet Cutting Systems: Precision Beyond the Workshop

- 3. Cordless Drills and Drivers: The Backbone of Every Installation

- 4. Cabinet Jacks and Leveling Systems: The Hidden Hands of Stability

- 5. Clamps and Fastening Systems: Holding Perfection in Place

- 6. Track Saws and Table Saws: The Heart of Precision Cutting

- 7. Routers and Edge Profiling Tools: Shaping the Character of Craft

- 8. Sanders and Surface Finishers: Perfecting Every Touchpoint

- 9. Nailers and Pneumatic Fastening Tools: Speed with Precision

- 10. Measuring Tapes, Squares, and Digital Calipers: The Language of Accuracy

- 11. Material Handling Equipment: Lifting Precision, Protecting Integrity

- 12. On-Site Dust Collection and Air Filtration Systems

- 13. Adhesive and Bonding Systems: Strength You Can’t See

- 14. Finishing Systems and Sprayers: The Art of Surface Perfection

- 15. Quality Assurance and Digital Calibration Tools

- Conclusion: Precision Tools, Timeless Craftsmanship

- 10 Frequently Asked Questions

1. Laser Levels: Setting the Foundation of Precision

Nothing defines professional cabinet installation more than precision alignment. Even a few millimeters off can alter door swings, disrupt countertop fits, or create unwanted gaps. Medalco relies heavily on rotary and cross-line laser levels to ensure every horizontal and vertical surface is perfectly aligned.

These lasers create a continuous line across walls and floors, guiding our team in real time as we install base and upper cabinets. Unlike traditional bubble levels, laser systems allow for multi-surface reference points, especially vital in complex spaces like open-plan kitchens or office suites.

Example from Medalco’s Work:

In a high-end penthouse project in Toronto, our installers used a self-leveling rotary laser to map a curved kitchen wall that integrated marble counters, metal trims, and custom glass shelving. This technology allowed us to synchronize the cabinet installation with the pre-cut stone panels fabricated in our shop using waterjet technology, ensuring a seamless visual flow.

Why It Matters:

Laser levels not only improve accuracy but also save installation time, reduce rework, and ensure that aesthetic details like shadow lines and surface transitions remain flawless.

2. Waterjet Cutting Systems: Precision Beyond the Workshop

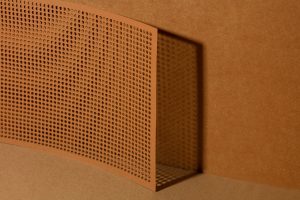

While not a tool used directly on-site, waterjet cutting plays a critical behind-the-scenes role in our cabinet installations. Medalco’s state-of-the-art waterjet systems enable us to fabricate custom components that integrate perfectly with cabinetry, such as metal trim inlays, stone backsplashes, or decorative panels.

Waterjet cutting uses a high-pressure stream of water, often with an abrasive additive like garnet, to slice through materials such as stone, metal, glass, and composite wood. The result is a clean, burr-free edge that requires minimal finishing.

How It Enhances Cabinet Installation:

- Perfect Fit Components: Custom stone or metal inserts for countertops or backsplashes are waterjet-cut to exact cabinet dimensions.

- Artistic Details: Intricate patterns or brand logos embedded in glass or stainless panels elevate the design.

- Multi-Material Compatibility: From cutting porcelain to aluminum, the process ensures dimensional consistency across materials.

Medalco Case Study:

In a boutique hotel renovation, we used waterjet-cut brass panels as cabinet door insets, complementing walnut veneer. The result was an elegant blend of warmth and luxury achieved with precision that only waterjet technology could provide.

Authoritative Resource:

Fabricators & Manufacturers Association: Waterjet Technology Overview

3. Cordless Drills and Drivers: The Backbone of Every Installation

If there is one tool that appears in every installer’s toolkit, it is the cordless drill. Medalco’s crews use professional-grade brushless motor drills and impact drivers designed for both speed and endurance.

Applications Include:

- Driving screws into hardwood frames or MDF panels

- Pre-drilling pilot holes for fasteners

- Installing cabinet handles, hinges, and drawer slides

The cordless advantage allows unrestricted movement around the site, while lithium-ion batteries ensure continuous operation. Medalco’s preference for variable-speed, torque-controlled models minimizes damage to delicate finishes, especially when working with fine hardwood veneers or painted surfaces.

Example from the Field:

During a recent residential kitchen upgrade, our installers used adjustable torque settings to prevent overtightening screws in soft maple cabinetry. This attention to detail not only preserved the integrity of the material but also maintained perfect hinge alignment.

Expert Reference:

Wood Magazine: Best Cordless Drills for Cabinetry

4. Cabinet Jacks and Leveling Systems: The Hidden Hands of Stability

Cabinet installation is a dance between gravity and geometry. Before securing upper units, our team uses cabinet jacks, adjustable lifting devices that support the weight of cabinets while we align and fasten them.

These tools are particularly critical for multi-unit installations or when working with oversized cabinets made from dense materials like stone-faced wood or stainless-clad panels.

Medalco’s Application:

In a luxury retail display project, our cabinet systems incorporated glass shelving supported by steel frames. Cabinet jacks allowed our installers to balance each section without manual strain, ensuring perfect joint alignment before final fastening.

Why It Matters:

Precision leveling ensures doors align seamlessly, drawers operate smoothly, and visual symmetry remains intact. Combined with laser measurements, these systems eliminate the guesswork from manual lifting and alignment.

Learn More:

This Old House: Tips for Installing Upper Cabinets

5. Clamps and Fastening Systems: Holding Perfection in Place

No matter how advanced the measuring tools, stability during installation is what ensures a lasting result. Medalco uses a variety of parallel clamps, corner clamps, and specialty cabinet connectors to hold units firmly in place while adhesives cure or screws are set.

For precision joinery, especially in tight spaces, these clamps act as an extension of the craftsman’s hands. In projects involving mixed materials like combining wood cabinetry with metal or stone inserts, custom jigs and adjustable clamps prevent surface marring and maintain alignment during fastening.

Example:

In a high-traffic commercial lobby project, our team installed cabinetry integrating brushed stainless steel and engineered stone fronts. Specialized rubberized clamps allowed us to maintain perfect seams without scratching the polished surfaces.

Pro Resource:

Popular Woodworking: Advanced Clamping Techniques

6. Track Saws and Table Saws: The Heart of Precision Cutting

When it comes to achieving clean, accurate cuts in cabinet components, no tools are more essential than saws. Medalco’s workshop and on-site teams rely heavily on track saws and table saws for trimming panels, adjusting cabinet sides, and fine-tuning joints.

A track saw glides along a guided rail to make straight, splinter-free cuts in sheet materials like plywood, MDF, and veneer panels. It ensures controlled motion and consistent accuracy, which is crucial when working with pre-finished surfaces. Table saws, on the other hand, handle larger or repetitive cuts and form the backbone of most cabinetry shops.

Medalco’s Approach:

We use high-precision table saws equipped with digital readouts and fine adjustment mechanisms, ensuring that every cut aligns with design specifications down to the millimeter. When a project calls for on-site modifications, our installers turn to portable track saws for reliable, dust-controlled performance.

Example from the Field:

During a custom office suite installation, Medalco’s team used a track saw system to resize engineered oak panels that formed a continuous wall of cabinetry. The precise edge quality allowed seamless integration with the stone countertop cut in our shop using waterjet technology, achieving a flawless material junction.

Pro Resource:

Woodworker’s Journal: Comparing Track Saws and Table Saws

7. Routers and Edge Profiling Tools: Shaping the Character of Craft

Beyond cutting and assembly, cabinetry is an art form defined by detail. The curves, bevels, and contours along edges give cabinets their distinct character. Medalco’s installers use routers, both handheld and table-mounted, to create professional-grade edge profiles and joinery cuts.

Applications Include:

- Creating decorative edges on door panels and trims

- Cutting dadoes or rabbets for cabinet joinery

- Smoothing sharp corners and transitions between materials

Modern routers allow interchangeable bits, enabling us to produce a range of shapes and depths tailored to each design. For projects that combine wood with metal or glass, we pair precision routing with waterjet-cut metal components, ensuring perfect fits between materials of different densities.

Medalco Example:

In a contemporary kitchen remodel, Medalco craftsmen used routers to shape walnut cabinet edges that complemented stainless steel inlays. The inlays had been precisely cut using our in-house waterjet machine, allowing an exact match between the organic wood contours and the metallic inserts.

Why It Matters:

Routing adds both tactile and visual sophistication to cabinetry, while maintaining structural integrity. The control offered by these tools helps Medalco achieve seamless transitions and premium finishes on every edge.

Authoritative Resource:

Canadian Woodworking: Router Techniques for Cabinetmakers

8. Sanders and Surface Finishers: Perfecting Every Touchpoint

Even the most precise joinery loses its appeal without a flawless surface. Sanding is where craftsmanship meets artistry. Medalco’s teams use orbital sanders, belt sanders, and finishing pads to create uniform, touch-smooth surfaces that are ready for finishing or painting.

Different Sanders for Different Jobs:

- Orbital Sanders: Ideal for finishing veneer or painted surfaces without swirl marks.

- Belt Sanders: Used for leveling uneven joins and removing large imperfections.

- Detail Sanders: Perfect for tight corners and curved moldings.

Case Study:

In a luxury condo project, our installers worked with high-gloss lacquered cabinetry. To achieve a mirror-quality surface, Medalco used multi-step sanding with micro-grit abrasives between coats. This precision ensured a flawless reflective finish, aligning perfectly with glass backsplash panels that were waterjet-cut to fit the cabinet dimensions.

Expert Tip:

The direction and progression of sanding grits matter. Medalco follows an exact sequence from coarse to ultra-fine, guaranteeing that the surface is both smooth and uniform under all lighting conditions.

Resource:

Fine Woodworking: Sanding for a Perfect Finish

9. Nailers and Pneumatic Fastening Tools: Speed with Precision

Efficiency is key in large-scale cabinet installations. Medalco incorporates pneumatic nailers, brad nailers, and finish nailers to accelerate assembly without compromising precision.

These air-powered tools are perfect for securing trim pieces, backing panels, and molding details quickly and cleanly. Adjustable depth settings prevent overdriving nails and damaging fine wood finishes.

Medalco in Action:

During a retail interior buildout, our installation crew used pneumatic brad nailers to attach maple trims and decorative valances across multiple cabinet runs. The consistent pressure from these tools ensured uniform fastening and reduced overall installation time by nearly 30 percent.

When working with dense materials such as metal-veneered MDF or stone-clad cabinetry, Medalco often pre-drills using precision bits and applies controlled air pressure to avoid cracking or deformation.

Why It Matters:

Pneumatic tools streamline workflow, allowing for consistent, high-quality results that meet tight project deadlines. They embody the balance Medalco strives for between craftsmanship and productivity.

Reference:

Family Handyman: Choosing the Right Nailer for Woodwork

10. Measuring Tapes, Squares, and Digital Calipers: The Language of Accuracy

Behind every cabinet that fits flawlessly, there is measurement accuracy that leaves no room for error. Medalco technicians rely on a combination of traditional and digital measuring tools, including precision tapes, framing squares, and calipers.

Our Measurement Arsenal:

- Steel Measuring Tapes: Durable, flexible, and ideal for quick on-site checks.

- Combination Squares: Ensure 90-degree accuracy for joinery and alignment.

- Digital Calipers: Allow exact readings for intricate cuts and component adjustments.

Accuracy in measurement is especially vital when working with multi-material assemblies. A metal edge or stone overlay cut with a waterjet must match the wooden base cabinet perfectly. By using digital calipers in tandem with our CAD-based fabrication models, Medalco ensures that the pieces fit seamlessly during final assembly.

Example:

For a modern kitchen featuring aluminum accent strips along oak cabinetry, our team used digital calipers to confirm the precise groove depth for metal insets before installation. The components, pre-cut via waterjet, aligned within a tolerance of 0.2 millimeters, resulting in an uninterrupted visual line across multiple units.

Professional Insight:

Accurate measurement is not just about numbers. It is the language through which design intent becomes physical reality. Every Medalco project begins and ends with measurement validation to ensure both technical accuracy and visual harmony.

Pro Resource:

Architectural Digest: The Importance of Precision in Modern Craftsmanship

11. Material Handling Equipment: Lifting Precision, Protecting Integrity

Cabinetry installation often involves moving and positioning large, heavy, and fragile components. Many of the materials we work with—such as stone countertops, glass panels, or metal-framed cabinet fronts—require specialized handling tools that preserve both material and human safety.

Key Equipment Medalco Uses:

- Panel Lifts: Allow safe positioning of upper cabinets without physical strain.

- Vacuum Lifters: Ideal for glass, stone, and polished metal surfaces, ensuring no scratching or edge damage.

- Dollies and Glide Systems: Used to maneuver cabinets or countertops across finished floors without marking them.

Medalco in Practice:

In a luxury condominium kitchen where cabinets were combined with marble waterfall counters and brass accents, we used vacuum lifters to raise and align the stone-clad surfaces with millimeter precision. This method prevented micro-chipping along the edges, preserving the fine polish created by our waterjet cutting system.

Why It Matters:

Material handling is as much about artistry as it is about safety. Protecting the integrity of custom finishes and precision-cut materials ensures the long-term durability and aesthetic quality that Medalco guarantees.

Learn More:

Woodworking Network: Safe Material Handling in the Shop and On-Site

12. On-Site Dust Collection and Air Filtration Systems

Cabinet installation sites can quickly become dusty environments, especially when working with MDF, particleboard, or solid wood. For Medalco, maintaining a clean and healthy workspace is a core part of professional conduct. That is why we employ mobile dust extraction systems that connect directly to cutting and sanding tools.

Features of Medalco’s Dust Control Systems:

- HEPA Filtration: Captures micro-particles that affect air quality and finish surfaces.

- Automatic Activation: Dust extractors start and stop in sync with the connected tool.

- Anti-Static Hoses and Filters: Prevent buildup of fine dust that could damage sensitive electronic components in modern cabinetry systems.

Case Example:

During the installation of a boutique retail cabinetry line finished in matte lacquer, our team used synchronized vacuum systems with orbital sanders to prevent airborne dust from settling on the cured surfaces. This process maintained the flawless matte texture throughout the project.

The Benefit:

Clean air and dust-free surfaces mean superior finishes, healthier working conditions, and faster cleanup. For Medalco, dust management is not just a compliance measure; it is a reflection of care for our craft and our clients’ spaces.

Reference:

Fine Homebuilding: The Role of Dust Collection in Professional Carpentry

13. Adhesive and Bonding Systems: Strength You Can’t See

Behind every perfectly aligned cabinet joint or invisible seam lies a powerful bonding system. Medalco’s installers rely on high-performance adhesives, epoxies, and construction-grade bonding agents that ensure lasting stability.

Types of Adhesives Used:

- PVA (Polyvinyl Acetate): Common for wood-to-wood bonding with quick setup time.

- Polyurethane Adhesives: Ideal for mixed materials like wood-to-metal or wood-to-glass.

- Epoxy Systems: Used for heavy-duty applications and moisture-prone areas such as kitchens and bathrooms.

How Medalco Applies Bonding Systems:

When assembling cabinetry that incorporates metal trims or natural stone elements, we use flexible adhesives that accommodate the different expansion rates of materials. This approach prevents cracking or warping over time and maintains a seamless look.

Example from Medalco Projects:

In a modern restaurant fit-out, Medalco’s design included wooden cabinets faced with brushed aluminum and integrated LED lighting channels. The bonding was achieved through a specialized epoxy system compatible with both conductive metal and porous wood, resulting in a structure that was both strong and visually clean.

Pro Resource:

The Adhesive and Sealant Council: Material Bonding in Mixed-Material Fabrication

14. Finishing Systems and Sprayers: The Art of Surface Perfection

The final aesthetic of cabinetry depends largely on the finishing process. Medalco uses HVLP (High Volume, Low Pressure) sprayers and precision-controlled finishing booths to achieve surfaces that are smooth, even, and durable.

Why We Prefer HVLP Sprayers:

- They produce fine atomization, reducing overspray and material waste.

- They create consistent coatings, ensuring color and texture uniformity.

- They allow precise control in confined spaces or intricate cabinetry shapes.

Material Compatibility:

From oil-based stains and waterborne lacquers to high-gloss polyurethane finishes, Medalco tailors its approach to the specific needs of each project. For example, when finishing wooden cabinetry adjacent to waterjet-cut glass or metal components, we apply additional masking and airflow control to protect reflective materials from micro-particle overspray.

Real-World Example:

In a series of luxury kitchen installations, our finishing team achieved a flawless satin sheen on walnut cabinetry by layering three coats of polyurethane with controlled curing times. The same kitchens featured marble backsplashes and aluminum trims cut via Medalco’s waterjet systems, and the consistent finish tied all materials together visually.

Learn More:

Architectural Woodwork Institute: Finishing Standards for Professional Woodwork

15. Quality Assurance and Digital Calibration Tools

Before any Medalco project reaches completion, it undergoes a rigorous quality assurance process involving both digital and manual verification.

Our Quality Tools Include:

- Digital Angle Finders: Ensure corner alignments and miters meet design tolerances.

- Moisture Meters: Verify that wood materials are conditioned for the environment before and after installation.

- Surface Calibrators: Measure cabinet faces and seams for uniformity and balance.

How It Works:

Using these instruments, our team confirms that every cabinet aligns perfectly within the design layout, functions smoothly, and meets Medalco’s strict standards of precision.

Example:

During a custom library installation featuring cherry wood cabinetry and glass shelving, Medalco’s team used digital angle meters to align miters between glass and wood sections, maintaining consistent geometry throughout the room.

Why It Matters:

Quality assurance transforms craftsmanship into excellence. By verifying every angle, joint, and dimension, Medalco ensures that what is built matches the architect’s vision and endures daily use for years to come.

Authoritative Resource:

Woodworking Network: Precision Measuring and Calibration Tools for Installers

Conclusion: Precision Tools, Timeless Craftsmanship

Every Medalco installation represents more than assembly; it is the art of transforming raw materials into enduring design. From the first measurement to the final polish, each step is guided by precision, experience, and the right tools.

The tools and systems we use, lasers, saws, routers, clamps, and waterjet technology—are not just instruments; they are extensions of our commitment to quality. They ensure that every cabinet, no matter how complex, fits its space flawlessly, functions perfectly, and stands the test of time.

By integrating cutting-edge fabrication and artistic craftsmanship, Medalco continues to elevate cabinetry to architectural excellence. Our waterjet-cut stone inlays, metal trims, and custom glass details demonstrate how technology can merge seamlessly with human creativity.

For clients and designers alike, this approach means more than a beautiful finish, it guarantees reliability, precision, and pride in every installation.

At Medalco, we build cabinetry not just to fit spaces, but to define them.

10 Frequently Asked Questions

1. What makes Medalco’s cabinet installations different from standard contractors?

Medalco integrates advanced fabrication technologies like waterjet cutting with traditional craftsmanship. This combination ensures not only aesthetic precision but also long-term durability. Each project is customized to the client’s design vision and material specifications.

2. How does waterjet cutting contribute to cabinet installations?

Waterjet cutting allows us to create perfectly sized components, inlays, and decorative accents from materials such as stone, metal, glass, and engineered composites. These pieces are integrated into cabinetry with exact tolerances, producing sleek and consistent results without heat distortion or surface damage.

3. What materials does Medalco commonly work with in cabinetry projects?

We frequently work with solid wood, MDF, plywood, engineered veneers, natural stone, metals like stainless steel and brass, and architectural glass. Our multi-material expertise allows for sophisticated designs where materials complement one another seamlessly.

4. How do you ensure perfect alignment and leveling during installation?

Medalco uses laser levels, digital measuring tools, and cabinet jacks to achieve precision alignment. These systems eliminate manual error and ensure consistent spacing, level surfaces, and visual balance across every installation.

5. Are Medalco’s installation tools suitable for both residential and commercial projects?

Yes. Our toolset and systems are designed to scale. Whether it is a high-end residential kitchen or a large commercial installation, Medalco’s approach remains consistent: precision, safety, and unmatched finish quality.

6. How do you protect surfaces during the installation process?

We use vacuum lifters, soft-edge clamps, and non-marring pads to handle delicate materials like polished stone and metal veneers. Additionally, on-site dust collection systems prevent fine particles from settling on finished surfaces.

7. Can Medalco fabricate custom elements that integrate with cabinetry?

Absolutely. Our custom fabrication services allow us to design and produce unique pieces such as waterjet-cut stone backsplashes, decorative metal trims, or glass inserts that fit perfectly within the cabinetry structure.

8. What role does finishing play in your cabinetry projects?

Finishing is one of the most important stages. Using HVLP sprayers and controlled finishing environments, we apply uniform coatings that protect and highlight the material’s natural beauty. Each finish is chosen to match the design intent and performance requirements.

9. How do you maintain quality control throughout the project?

Medalco follows a multi-stage inspection process. Using digital calibration tools such as angle meters and moisture sensors, our team ensures that every element meets exact tolerances before final approval. We also test cabinet functionality on-site to guarantee smooth operation.

10. How can clients begin a project with Medalco?

The process begins with a consultation to understand the client’s vision, space requirements, and preferred materials. From there, we create detailed CAD drawings and prototypes. Once approved, fabrication begins in our facility, followed by on-site installation with full project oversight.

Trusted External Resources

- Insights on trends and best practices in custom cabinetry and wood fabrication.

- Leading source for stone cutting and finishing technologies.

- Covers innovations in metal cutting and forming.

- Authority on glass processing and architectural integration.

- Technical resource on CNC, waterjet, and other precision fabrication tools.