10 Game-Changing Lessons We Learned from Real Waterjet Cutting Challenges

Instead of hiding those struggles, we’re proud to share them. Why? Because every challenge has taught us something invaluable about quality, craftsmanship, technology and, most importantly, about delivering excellence to our clients.

In this article, we’ll share the top 10 lessons we’ve learned from real-world waterjet cutting challenges. These are hard-earned insights that now shape how Medalco approaches every project, from luxury interiors to intricate stone decor.

1. Precision Starts with Preparation

When we first started working with complex cabinet and stone designs, we learned quickly that accuracy isn’t just about the machine it’s about what you feed into it.

Waterjet machines require perfectly prepared design files (usually DXF or DWG). One minor flaw in the vector file—a gap, an unjoined path, or an open curve can derail an entire cut. Early on, this cost us time and materials.

Lesson: Invest in clean CAD drawings, double-check for open contours, and collaborate closely with designers before the job hits the machine.

2. Different Materials Behave Differently Under Pressure

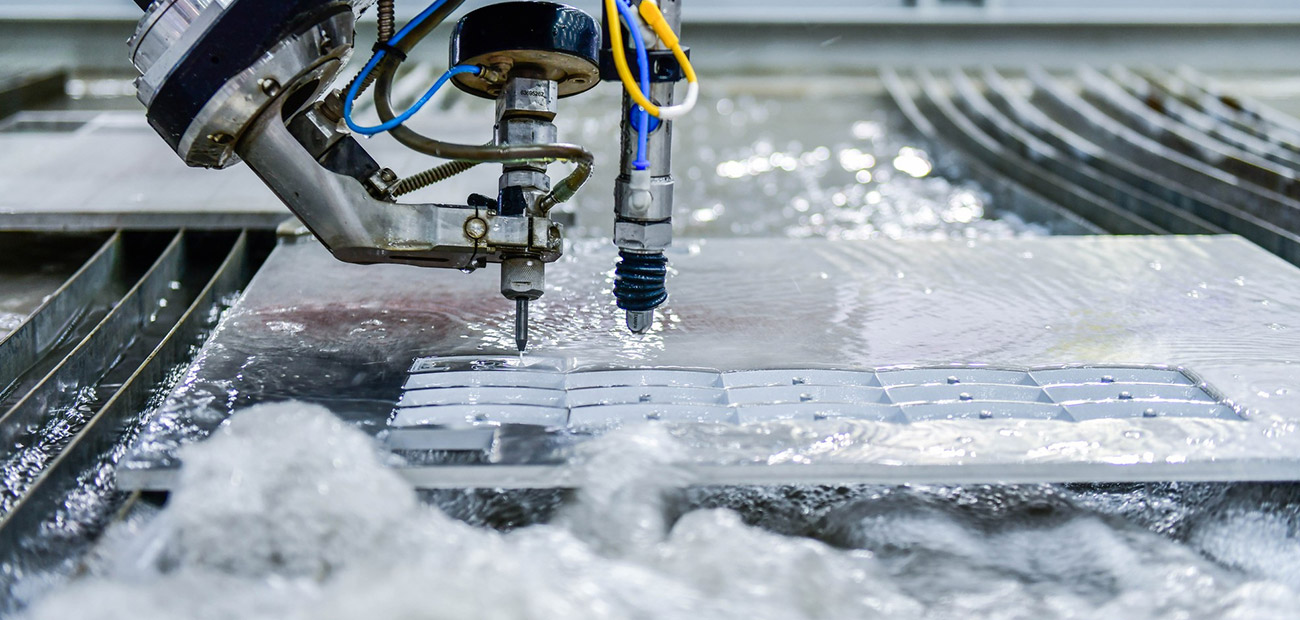

Waterjet cutting is non-thermal, meaning it doesn’t create heat distortion. That’s a big plus—but it doesn’t mean all materials react the same.

- Stone, for example, can chip at the edges if the jet is too aggressive.

- Wood may swell slightly from moisture if not sealed or treated properly.

- Glass demands specific speeds and abrasives to avoid cracking.

- Metals like aluminum or brass cut beautifully, but require tighter tolerance management.

Lesson: Adjust pressure, speed, and abrasive levels based on material. One size doesn’t fit all.

3. Tolerances Are Everything in Multi-Part Projects

Medalco often creates intricate multi-piece inlays, especially for fireplaces, floor medallions, or backsplashes. If just one piece is off by even half a millimeter, the final installation won’t align.

Lesson: Don’t just cut for shape cut for fit. Know your material’s behavior post-cutting, especially for natural stone which can be brittle or inconsistent.

4. Maintenance Prevents Mid-Project Downtime

In one high-stakes hospitality project, our machine’s orifice wore out mid-run, causing a 2-day delay. We learned that regular maintenance—like replacing garnet feed tubes and checking water pressure valves—isn’t optional.

Lesson: Preventive maintenance beats emergency fixes. Schedule it religiously

5. Complex Designs Require Layered Thinking

One of our most challenging waterjet projects involved a floral-patterned marble inlay for a luxury villa. Each petal had to nest precisely into its counterpart.

Instead of one monolithic drawing, we created separate layers by material type and depth of cut. This not only made the file easier to process but also allowed us to troubleshoot each part before final assembly.

Lesson: For detailed artistry, think in layers. Build a modular design plan.

6. Customer Communication Avoids Costly Redos

Clients sometimes underestimate how detailed waterjet work can be. In one case, a client wanted a metal sign with ultra-fine script, but the font wasn’t readable after cutting—it needed thicker strokes.

Lesson: Educate clients early. Provide digital previews, material samples, or even a small test cut before committing.

7. Every Drop of Water Counts Literally

Yes, waterjet is eco-friendly in many ways. But it still uses thousands of gallons of water per job. We learned to recycle water wherever possible and monitor consumption to remain sustainable.

Lesson: Be as precise in your resource use as you are in your cuts.

8. Abrasives Make or Break the Finish

Choosing the wrong garnet grit can lead to ragged edges or dull surfaces. We once used a coarse grit on a back-painted glass panel—only to see the paint scratch off from behind.

Now, we choose abrasives as carefully as our cutting paths.

Lesson: Know your grit. Finer doesn’t always mean better it depends on the job.

9. Not All Design Ideas Translate to Real-World Cuts

Some digital designs simply aren’t physically feasible, especially if they include unsupported islands, tight radii, or overlapping layers.

Medalco has developed a pre-flight review checklist that we now apply to every design. We look for weak points, impossible turns, or cuts that might cause breakage.

Lesson: Bridge the gap between design fantasy and manufacturing reality.

10. Your Team is Your Strongest Asset

Finally, we’ve learned that no machine however advanced can replace a skilled human team.

From CAD experts to machine operators and finishing technicians, everyone at Medalco brings insights that help anticipate problems before they happen.

Lesson: Invest in people. The best machines are only as good as the hands that run them.

Real-World Case Study: A Challenging Fireplace Inlay

A client approached us for a custom marble fireplace inlay featuring a compass rose pattern. The design included 22 pieces, all in different types of stone with varying hardness.

Here’s how we applied our lessons:

- Design review: We adjusted radii and spacing in CAD.

- Material prep: We tested each stone type with different pressures.

- Execution: We layered cuts and used fine abrasives.

- Teamwork: Everyone from design to installation collaborated closely.

The result? A seamless installation that delighted the client and expanded our design portfolio.

Common Materials We Work With at Medalco

- Natural Stone: Marble, granite, travertine – sensitive to chipping, requires slow and steady cuts

- Wood: Used in custom cabinets; sealed wood resists moisture better

- Glass: Needs gentle pressure and correct backing to avoid shatter

- Metal: Aluminum, brass, stainless steel – each requires different nozzle speeds and pressure

Why Waterjet Technology Matters in Design

Waterjet’s ability to cut virtually any material without heat distortion makes it ideal for both functional and artistic applications:

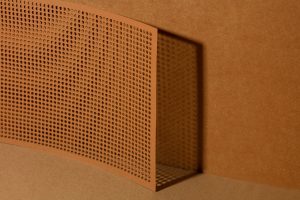

- Custom cabinetry detailing

- Intricate floor patterns

- Branded signage

- Interior stone paneling

At Medalco, we combine waterjet cutting with hand-finishing for results that are both precise and beautiful.

Conclusion: The Future Is Carved in Stone

Waterjet-cut stone art isn’t just a fleeting trend. It’s a new chapter in architectural storytelling one that fuses precision, sustainability, and awe-inspiring design.

With the rise of custom design, expect these panels to show up in more homes, hotels, and public spaces. As for what’s next? The technology will only get more refined and the designs even more breathtaking.

Final Call to Action

At Medalco, waterjet cutting is more than a service it’s an evolving craft. Our commitment to precision, design, and sustainability allows us to tackle ambitious projects across cabinetry, stonework, signage, and architectural installations.

Whether you’re a designer, contractor, or homeowner, let’s bring your boldest ideas to life.

Contact us today to discuss your next waterjet or custom fabrication project. We’re here to cut smart, cut clean, and cut beautifully.

10 Unique FAQs About Waterjet-Cut Stone Art Panels

| 1. What is waterjet cutting and how does it work? Waterjet cutting is a cold-cutting process that uses a high-pressure stream of water mixed with abrasive particles to slice through various materials with extreme precision without generating heat. |

| 2. Which materials can be cut using waterjet technology? Waterjet can cut stone, metal, wood, glass, ceramics, plastics, and even composites. Each material may require different pressures, nozzle settings, and abrasive types. |

| 3. Why choose waterjet cutting over laser or plasma cutting? Waterjet cutting doesn’t generate heat, so it avoids thermal distortion or hardening. It’s also capable of more intricate, multi-material cuts, making it ideal for detailed designs and sensitive materials. |

| 4. What are common challenges in waterjet cutting? Issues can include file preparation errors, abrasive selection problems, material behavior differences, machine maintenance needs, and unrealistic design expectations. |

| 5. How accurate is waterjet cutting for complex projects? Extremely accurate tolerances can be as tight as ±0.1 mm with the right setup. However, complex multi-piece designs require careful planning and CAD precision. |

| 6. Does waterjet cutting work well for artistic or architectural projects? Yes, it’s perfect for intricate inlays, stone murals, branded panels, and custom cabinetry details. Medalco frequently uses waterjet in high-end architectural and interior projects. |

| 7. Is waterjet cutting environmentally friendly? Relatively so. It uses water and garnet, both recyclable in many systems. Medalco employs water recycling and careful resource management in its projects. |

| 8. How does Medalco handle multi-material fabrication? We optimize speed, pressure, and abrasives for each material. Our team has developed custom workflows and pre-flight file checks to ensure precise, seamless results across different mediums. |

| 9. What should clients provide to begin a waterjet project? Ideally, a well-prepared CAD file (like .DXF or .DWG), details about materials, desired finish, and any design constraints. Medalco also assists clients in refining their files for cutting. |

| 10. Can Medalco assist with design and post-processing? Absolutely. We provide full-service support from file optimization and cutting to hand-finishing and installation, ensuring a turnkey solution for designers and builders. |

Trusted External Resources

- OMAX Waterjet: Educational Articles

- Flow Waterjet: How Waterjet Works

- The Fabricator: Waterjet Cutting Insights

- Engineering.com: Waterjet vs Laser Comparison

- Architectural Digest: Stone in Interior Design