20 Challenges of Working with Natural Stone

Natural stone has fascinated humanity for centuries. From the marble temples of Greece to the granite countertops in modern homes, stone represents timeless beauty, strength, and endurance. Yet, behind every flawless installation lies a set of challenges that fabricators, designers, and installers must overcome. At Medalco, we know these challenges well. With years of experience in waterjet cutting, custom fabrication, and stone design, our team has seen both the struggles and the incredible rewards that come with working with natural stone.

This article explores the 20 challenges of working with natural stone, the lessons we have learned, and how Medalco continues to deliver precision, beauty, and durability in every project.

Table of contents

- 20 Challenges of Working with Natural Stone

- 1- Natural Variation in Color and Pattern

- 2- Fragility During Transport

- 3- Inconsistent Thickness

- 4- Susceptibility to Stains

- 5- Sensitivity to Acidic Substances

- 6- Difficulty of Precision Cuts

- 7- Heavy Weight of Stone

- 8- Limited Size of Slabs

- 9- High Cost of Material

- 10- Environmental Concerns

- 11- Installation Complexity

- 12- Temperature Sensitivity

- 13- Slipperiness of Polished Stone

- 14- Limited Flexibility in Design Changes

- 15- High Labor Costs

- 16- Matching Multiple Slabs

- 17- Dust and Health Hazards During Cutting

- 18- Limited Repair Options

- 19- Difficulty in Achieving Complex Shapes with Traditional Tools

- 20- Balancing Aesthetics and Functionality

- The Artistic, Architectural, and Practical Value of Waterjet Technology

- Conclusion: Turning Challenges into Masterpieces with Medalco

- Frequently Asked Questions (FAQs)

1- Natural Variation in Color and Pattern

Every slab of marble, granite, or limestone is unique. Unlike engineered materials, stone cannot be standardized. Clients often fall in love with a showroom sample, only to discover that the actual slab has different veining or color tones.

Medalco’s Approach: We help clients choose slabs in person and use waterjet cutting to highlight the most attractive sections. By mapping the grain before cutting, we ensure the final result showcases the stone’s natural beauty.

2- Fragility During Transport

Stone may be strong once installed, but it is surprisingly vulnerable during shipping. Large slabs can crack under their own weight if not handled correctly.

Example from Medalco: In one San Jose project, we transported oversized marble slabs for a luxury fireplace. Using specialized A-frames and vibration-resistant packing, we delivered the stone intact, ready for waterjet precision cuts.

3- Inconsistent Thickness

Unlike engineered boards, natural stone can have slight thickness variations. These differences complicate installation, especially when stones must align seamlessly.

Solution: Medalco uses CNC machinery to calibrate thickness where needed, ensuring smooth joints and even surfaces.

4- Susceptibility to Stains

Marble and limestone are porous, making them prone to staining from wine, oils, or even water.

Professional Tip: We recommend sealing porous stones immediately after installation. At Medalco, we guide clients in choosing the right sealants for long-lasting protection.

5- Sensitivity to Acidic Substances

Materials like marble and travertine can etch when exposed to acidic substances such as lemon juice or vinegar.

How Medalco Helps: We educate clients on maintenance and sometimes suggest engineered alternatives in high-risk areas.

6- Difficulty of Precision Cuts

Traditional tools often chip or fracture stone edges. Waterjet cutting revolutionized this challenge by allowing smooth, chip-free cuts.

Medalco’s Expertise: With waterjet technology, we cut stone, metal, glass, and wood with unparalleled precision, making it possible to craft intricate inlays and architectural features.

7- Heavy Weight of Stone

Natural stone is heavy, which complicates handling, installation, and structural planning.

Case Study: For a large kitchen island project, Medalco coordinated with structural engineers to reinforce cabinetry before installing a massive granite slab.

8- Limited Size of Slabs

Clients often want large, seamless pieces, but natural stone slabs have size limitations.

Solution: Medalco designs strategic seam placements and uses waterjet precision to make seams nearly invisible.

9- High Cost of Material

Premium stones such as Calacatta marble or exotic granites are expensive. Mistakes in cutting can be financially devastating.

Our Advantage: Waterjet and CNC technology reduce waste by optimizing cutting layouts, saving both material and cost.

10- Environmental Concerns

Stone quarrying has environmental impacts, including energy use and landscape disruption.

Reference: Natural Stone Institute emphasizes responsible sourcing. Medalco partners with suppliers who follow sustainable quarrying practices

11- Installation Complexity

Installing stone requires skill, precision, and patience. Uneven subfloors or walls can cause visible misalignments.

Medalco’s Process: Our installers perform thorough site preparation, ensuring every surface is ready for stone.

12- Temperature Sensitivity

Stone expands and contracts with temperature changes. Outdoors, this can lead to cracking if not installed with expansion joints.

Tip: Medalco’s designs account for environmental conditions, ensuring durability in both indoor and outdoor settings.

13- Slipperiness of Polished Stone

Polished marble or granite can be slippery, especially when wet.

Solution: We recommend honed finishes or anti-slip treatments in bathrooms and entryways.

14- Limited Flexibility in Design Changes

Once stone is cut, design modifications are difficult. Unlike wood or metal, it cannot be easily reshaped.

Our Approach: Medalco’s 3D modeling and precise waterjet programming minimize the risk of last-minute changes.

15- High Labor Costs

Working with stone requires skilled artisans, and labor costs can be higher compared to other materials.

Reality Check: While initial costs may be higher, stone offers unmatched longevity and artistic value.

16- Matching Multiple Slabs

For large projects, multiple slabs must be book-matched or vein-matched for aesthetic continuity.

Medalco Example: In a luxury lobby project, we used waterjet scanning to align book-matched marble slabs, creating a stunning mirror effect.

17- Dust and Health Hazards During Cutting

Stone cutting generates silica dust, which can be harmful if not managed properly.

Reference: OSHA Silica Standards provide guidelines for safe handling. Medalco uses waterjet cutting, which virtually eliminates airborne dust.

18- Limited Repair Options

If stone chips or cracks after installation, repair can be difficult and sometimes impossible to hide.

Medalco’s Preventive Method: Our fabrication process minimizes weak points, reducing the risk of damage.

19- Difficulty in Achieving Complex Shapes with Traditional Tools

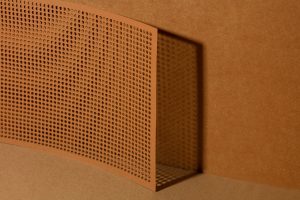

Curves, mosaics, and detailed engravings are nearly impossible with saws.

Advantage of Waterjet: Medalco’s waterjet machines handle detailed shapes effortlessly, allowing us to create artistic inlays that combine stone, glass, and metal.

20- Balancing Aesthetics and Functionality

Choosing the right stone is a balance between beauty and practicality. A highly veined marble might look spectacular but may not be suitable for a high-traffic kitchen.

Medalco’s Promise: We guide clients toward the perfect balance, ensuring designs that are not only breathtaking but also functional and durable.

The Artistic, Architectural, and Practical Value of Waterjet Technology

Waterjet cutting is more than a fabrication method. It is a bridge between nature’s raw beauty and human creativity. At Medalco, we use it to transform heavy stone slabs into works of art. From cabinet inlays to stone wall panels, the precision of waterjet cutting allows us to respect the integrity of stone while unlocking design possibilities that were once impossible.

Conclusion: Turning Challenges into Masterpieces with Medalco

Working with natural stone is not for the faint of heart. The challenges are real, ranging from material fragility to design complexity. Yet, with the right expertise and technology, those challenges transform into opportunities. At Medalco, we pride ourselves on guiding clients through these hurdles with precision waterjet cutting, expert fabrication, and a deep respect for the artistry of stone.

If you are planning a project that involves stone, metal, glass, or wood, let Medalco be your trusted partner. Our team will help you harness the beauty of natural stone while avoiding costly mistakes.

Call Medalco today to discuss your project or schedule a consultation. Let’s transform nature’s masterpiece into your masterpiece.

Frequently Asked Questions (FAQs)

| 1. What are the main challenges of working with natural stone? The main challenges include fragility, weight, staining, thickness variations, and the difficulty of achieving precise cuts without advanced technology. |

| 2. Why is transporting natural stone so difficult? Natural stone slabs are heavy and prone to cracking during transit, requiring special handling, frames, and vibration-resistant packing. |

| 3. How does waterjet cutting help with natural stone fabrication? Waterjet cutting allows for chip-free, precise cuts, making it possible to create detailed shapes and reduce waste in stone fabrication projects. |

| 4. What types of natural stone are most difficult to work with? Marble and limestone can be challenging due to their porosity and sensitivity to acids, while granite poses challenges due to its hardness. |

| 5. Can natural stone be repaired if it cracks after installation? Repairs are possible but often visible. Prevention through proper fabrication and installation is the best way to avoid costly damage. |

| 6. How does Medalco handle design changes once stone is cut? Medalco minimizes risks with 3D modeling and precise waterjet programming, but major changes after cutting are usually limited. |

| 7. Is working with natural stone more expensive than engineered materials? Yes, due to higher material and labor costs. However, natural stone offers unmatched beauty, durability, and timeless value. |

| 8. What safety concerns exist when cutting natural stone? Traditional cutting generates silica dust, which is hazardous. Medalco uses waterjet technology, eliminating airborne dust risks. |

| 9. How do environmental factors affect natural stone installations? Temperature changes can cause expansion and cracking, while outdoor settings require special installation methods for durability. |

| 10. Why choose Medalco for natural stone projects? Medalco combines waterjet cutting, expert fabrication, and custom design to transform natural stone challenges into stunning architectural results. |

Trusted External Resources

- Standards and sustainability in stone.

- Safety guidelines for stone fabrication.

- Architectural insights and case studies using stone.

- Scientific studies on stone performance.

- Technical standards for stone design.