10 The Fabrication Phase of Building Closets That Fit

Introduction

The Evolution of Closets: From Storage to Lifestyle Statement

Closets are no longer just storage spaces. In modern homes, they have become a reflection of personality, lifestyle, and organization. Whether you are talking about a walk-in closet with elegant cabinetry, a compact reach-in system, or a custom wardrobe solution, the fabrication phase is where design ideas transform into tangible structures. It is where precision, craftsmanship, and technology merge to create closets that not only fit perfectly but also elevate the aesthetics of the space.

Medalco’s Expertise: Custom Fabrication and Material Innovation

At Medalco, our expertise in waterjet cutting, custom fabrication, and cabinetry design has positioned us as a trusted partner for homeowners, designers, and architects looking for one-of-a-kind closet solutions. By working with a combination of materials such as wood, stone, metal, and even glass, we ensure that every closet fabrication project meets the highest standard of function and beauty.

Key Fabrication Considerations: Technology, Precision, and Design

In this article, we will explore ten critical aspects of the fabrication phase for building closets that fit seamlessly into your space. Along the way, we will highlight case studies from Medalco’s portfolio, review the role of materials, and discuss how advanced technologies like CNC and waterjet cutting contribute to flawless execution.

Table of contents

- 10 The Fabrication Phase of Building Closets That Fit

- Introduction

- Why the Fabrication Phase Matters

- Step 1: Precision Measurement Before Fabrication

- Step 2: Material Selection and Its Impact on Fabrication

- Step 3: CNC and Waterjet Cutting in Closet Fabrication

- Step 4: Edge Banding for Professional Finishes

- Step 5: Structural Reinforcement and Assembly

- Step 6: Integrating Hardware During Fabrication

- Step 7: Customization and Personalization

- Step 8: Finishing and Surface Treatments

- Step 9: Quality Control in Fabrication

- Step 10: Preparing for Installation

- The Role of Technology in Modern Fabrication

- Real-World Example: A Medalco Luxury Closet

- The Artistic Value of Fabrication

- The Architectural Dimension of Closet Fabrication

- Material Behavior in Fabrication

- The Practical Value of Waterjet in Fabrication

- Medalco’s Integrated Process

- Why Precision Matters in Closets

- Conclusion: Why Medalco is the Choice for Custom Closet Fabrication

- Frequently Asked Questions (FAQs)

Why the Fabrication Phase Matters

The fabrication stage is often underestimated in home improvement projects. Many clients focus heavily on design or material selection without fully understanding that fabrication is the bridge between vision and reality. It is here that measurements become cuts, raw materials transform into panels, and design lines emerge as tangible cabinetry.

Closets that fail to fit properly often share a common issue: poor fabrication practices. These mistakes can result in gaps, misaligned doors, or wasted space. By contrast, precise fabrication ensures a flawless fit, maximizes storage, and preserves the intended design.

At Medalco, our fabrication process includes a combination of CNC machining, waterjet technology, and artisan finishing. This balance allows us to execute at the level of both engineering accuracy and design artistry.

Step 1: Precision Measurement Before Fabrication

The first stage in fabrication begins long before a saw or waterjet blade touches the material. It starts with precision measurement. In closet systems, every millimeter counts. A minor miscalculation can translate into doors that do not close correctly or shelving that wobbles.

Case Example from Medalco: In a San Jose custom walk-in project, our team measured the client’s space multiple times with both digital laser tools and traditional manual methods. The closet had unusual angles and a slightly sloped ceiling. By capturing every nuance in measurement, we avoided costly reworks and ensured a perfect installation on the first attempt.

Why Measurement Matters:

- Prevents material waste

- Ensures alignment of panels and doors

- Maximizes usable space

Step 2: Material Selection and Its Impact on Fabrication

Closets can be built from a wide range of materials, each behaving differently during fabrication.

- Wood (Solid and MDF): Classic and versatile, wood requires careful cutting and edge banding. MDF is excellent for painted finishes but needs reinforcement to avoid sagging.

- Plywood: Stronger than MDF and ideal for load-bearing shelving.

- Stone: Rare in closet interiors but increasingly used for luxury countertops or accent surfaces. Waterjet cutting is the only way to achieve precise shapes without cracks.

- Metal: Often integrated for modern aesthetics or support elements. Needs precision cutting and finishing to prevent sharp edges.

- Glass: Popular for closet doors and inserts, requiring accurate waterjet or CNC cutting to fit hardware securely.

Medalco’s Expertise: Our waterjet technology allows us to handle even delicate materials like glass or intricate metal inserts for closet doors. For wood, CNC cutting ensures clean edges and exact sizing, especially in complex layouts.

Step 3: CNC and Waterjet Cutting in Closet Fabrication

Traditional woodworking relies heavily on manual cutting and joining. While skilled carpentry remains essential, advanced tools like CNC routers and waterjet machines redefine what is possible in closet fabrication.

- CNC Cutting: Perfect for wood and MDF panels, CNC ensures precise sizing and flawless edge preparation for edge banding.

- Waterjet Cutting: Useful when incorporating stone countertops, glass panels, or decorative metal accents into closet systems. The technology cuts with a stream of water and abrasive particles, leaving smooth, chip-free edges.

Case Example from Medalco: In one of our luxury closet projects, the client requested frosted glass panels with geometric patterns. Using waterjet cutting, we were able to etch and shape glass panels that fit seamlessly into wooden doors, achieving both durability and design flair.

Step 4: Edge Banding for Professional Finishes

Edge banding may seem like a minor detail, but it plays a pivotal role in closet fabrication. Properly banded edges give closet panels a clean, professional look while protecting them from moisture and wear.

CNC-controlled edge banding machines have improved the precision and consistency of this process. At Medalco, we integrate both CNC and manual craftsmanship for high-touch quality.

Benefits of Edge Banding:

- Enhances durability

- Provides a sleek and seamless finish

- Protects panels from moisture damage

Fabrication Tip: Always match the banding color and texture with the core material to achieve a cohesive appearance.

Step 5: Structural Reinforcement and Assembly

Even the most beautiful closets are useless if they cannot bear weight. Reinforcement is a critical step in fabrication, ensuring shelving can support clothing, shoes, and accessories without sagging.

Techniques Used:

- Reinforced plywood back panels for stability

- Hidden brackets for floating shelves

- Integrated lighting channels fabricated with CNC precision

Medalco Case Study: In one project, a client wanted long-span floating shelves for handbags. Instead of using traditional brackets, we designed CNC-milled supports embedded directly into the wall panels. The result was both visually clean and structurally sound.

Step 6: Integrating Hardware During Fabrication

Hardware is the silent hero of closet systems. Hinges, drawer slides, handles, and pull-out racks all play a role in functionality. Poorly chosen or incorrectly installed hardware can make even the most beautiful closet frustrating to use.

At Medalco, hardware integration happens during the fabrication phase, not as an afterthought. By planning cutouts, drilling holes, and embedding hardware channels using CNC precision, we avoid alignment issues during installation.

Examples of Hardware Considerations:

- Soft-close hinges: Require precise drilling depth and alignment.

- Drawer slides: Must be leveled perfectly for smooth operation.

- Pull-out racks and organizers: Benefit from CNC-cut slots for secure mounting.

- Lighting strips: Often routed into panels with CNC machines for a sleek, built-in look.

Case Study: A client wanted hidden LED lighting in every drawer. Medalco’s fabrication team routed narrow channels into drawer sides, embedding LED strips flush with the wood. The wiring was concealed during assembly, creating a clean, modern effect.

Step 7: Customization and Personalization

Closets are highly personal spaces. Unlike kitchen cabinetry, closets often hold items of sentimental or high personal value. During fabrication, customization is the difference between a generic system and a dream closet.

Customization can include:

- Jewelry drawers with felt-lined compartments

- Pull-out shoe racks

- Adjustable shelving

- Mirrored panels

- Hidden safes or compartments

Medalco’s Role: Our waterjet and CNC capabilities allow us to go beyond standard box-like construction. For example, we fabricated custom inserts with intricate cutouts to hold luxury watches, ensuring both security and elegance.

Real Example: In one project, a client asked for a hidden storage compartment within their walk-in closet. Using waterjet-cut steel and CNC-milled wood, we integrated a lockable safe that blended seamlessly with the cabinetry.

Step 8: Finishing and Surface Treatments

Fabrication is not complete without proper finishing. The finish determines not just the look but also the durability of the closet.

Popular Finishing Options:

- Wood Veneer: Adds warmth and natural appeal.

- Laminates: Durable and available in endless textures and colors.

- Painted MDF: Offers a smooth, modern look with customizable colors.

- Stone Accents: Used for countertops or decorative surfaces, cut precisely with waterjet technology.

- Glass Inserts: Frosted or clear panels fabricated to size.

At Medalco, finishing is approached with the same precision as cutting. Panels are sanded, sealed, and treated to withstand daily wear. If stone is used, waterjet finishing ensures chip-free edges. For wood, CNC routing creates surfaces ready for paint or veneer application.

Case Study: A San Jose homeowner requested a closet with walnut veneer and stone accents. Medalco fabricated stone-topped shelving using waterjet precision, ensuring seamless joints with the wood veneer panels.

Step 9: Quality Control in Fabrication

Before leaving the workshop, every fabricated piece must pass a strict quality control process. This step is crucial for closets, as even small flaws become noticeable when panels are assembled in the home.

Our QC Process at Medalco:

- Dimensional Accuracy: Panels are measured against digital design files.

- Surface Inspection: Checking for chips, scratches, or uneven finishes.

- Hardware Testing: Hinges, slides, and moving parts are tested for durability.

- Mock Assembly: In complex projects, we perform partial test assemblies to confirm fit before shipping.

Example: For a recent project involving mirrored sliding doors, our team tested the rolling mechanism multiple times in-house before installation. By catching issues early, we avoided on-site complications.

Step 10: Preparing for Installation

The fabrication phase concludes with preparation for delivery and installation. This involves:

- Labeling each panel and part for easy assembly

- Packaging materials carefully to prevent damage in transit

- Pre-drilling where possible to streamline on-site work

Medalco emphasizes efficiency here. By fabricating with installation in mind, our teams can install closets faster with fewer adjustments needed on-site. This saves clients time and reduces costs associated with delays.

Case Study: For a commercial project involving multiple closet units, Medalco pre-drilled hardware holes and labeled each component with QR codes linked to assembly diagrams. This approach cut installation time by nearly 40 percent.

The Role of Technology in Modern Fabrication

Technology has transformed closet fabrication from a largely manual process into a blend of engineering and artistry. At Medalco, we use:

- CNC Routing: For cutting wood and MDF with unmatched precision.

- Waterjet Cutting: For intricate stone, glass, and metal details.

- 3D Design Software: For simulating closet layouts before fabrication begins.

- Laser Measurement: For exact room dimensions, reducing fabrication errors.

This combination ensures that what clients see in the design phase is exactly what they receive in their homes.

Real-World Example: A Medalco Luxury Closet

One of our most notable projects involved fabricating a bespoke walk-in closet for a Silicon Valley home. The client wanted a blend of modern design and natural materials.

- Materials Used: Walnut veneer, frosted glass, brushed aluminum accents, and a marble countertop for the island.

- Fabrication Process:

- CNC-cut walnut panels for exact fit.

- Waterjet-cut marble slab for the island top, with polished edges.

- Custom LED lighting channels integrated into shelves.

- Hidden safe embedded into the cabinetry.

- Outcome: A closet that fit perfectly within the space, offering both luxury and practicality.

The client later commented that the closet felt “like walking into a boutique every morning.

The Artistic Value of Fabrication

Closet fabrication is more than assembling panels and shelves. It is about crafting a space that feels intentional, tailored, and beautiful. At Medalco, our approach blends precision engineering with artistry.

Think of a closet as a stage. Every drawer is a supporting character, every finish a costume, and every detail contributes to the performance. When fabricated with care, a closet becomes a luxurious experience rather than just a storage area.

How Medalco Elevates Closet Design:

- Custom Waterjet-Cut Accents: Decorative stone or metal inlays in shelving or doors.

- Unique Drawer Faces: CNC-carved patterns that create a boutique-like aesthetic.

- Architectural Integration: Aligning closets with existing trim, flooring, and lighting schemes.

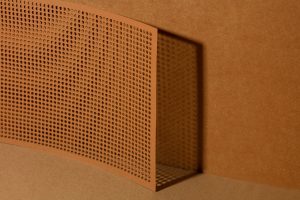

Case Example: A client requested doors with geometric cutouts that allowed airflow while keeping clothes dust-free. Medalco used waterjet-cut aluminum panels with a powder-coated finish, blending art and function.

The Architectural Dimension of Closet Fabrication

Closets are architectural elements, not isolated furniture pieces. Properly fabricated closets should integrate seamlessly into the home’s structure.

Key Architectural Considerations:

- Proportions: Ensuring shelves and panels match ceiling height and room dimensions.

- Symmetry vs. Asymmetry: Creating balance while leaving room for creative design.

- Transitions: Smooth connections between closet systems and adjacent walls or flooring.

- Lighting: Embedding lighting into architectural elements rather than attaching it later.

Real Example: For a modern townhouse project, Medalco fabricated a floor-to-ceiling wardrobe wall. Using waterjet-cut glass and CNC-milled wood, we created sliding panels that aligned perfectly with the home’s wall lines, making the closet feel built-in and integral to the space.

Material Behavior in Fabrication

Every material behaves differently during fabrication. Understanding these behaviors is crucial for closets that last. Medalco’s workshop handles a variety of materials, often combining them for unique results.

Wood

- Strengths: Warm, versatile, customizable with veneers.

- Challenges: Can warp if not sealed; requires CNC precision for joints.

- Medalco Approach: We select kiln-dried hardwoods and apply precision routing to prevent warping and misalignment.

Stone

- Strengths: Durable, luxurious, perfect for countertops and accents.

- Challenges: Prone to chipping with traditional tools.

- Medalco Advantage: Waterjet cutting creates clean, chip-free edges on marble, granite, or quartz.

Metal

- Strengths: Adds strength and modern elegance.

- Challenges: Requires specialized cutting to avoid heat distortion.

- Medalco Advantage: Waterjet technology cuts metal without heat, preserving structural integrity.

Glass

- Strengths: Light-enhancing, creates openness.

- Challenges: Breaks easily with mechanical saws.

- Medalco Advantage: Our waterjet system handles glass delicately, achieving smooth curves and edges.

Case Study: A luxury closet project required a floating glass shelf supported by steel brackets. Medalco fabricated waterjet-cut steel frames and glass panels, ensuring both strength and visual lightness.

The Practical Value of Waterjet in Fabrication

Why does waterjet matter so much in closet fabrication? The answer lies in precision and versatility.

- Non-Heat Cutting: Unlike lasers or saws, waterjet cutting does not burn, crack, or warp materials.

- Versatility: Cuts stone, metal, glass, and wood with equal ease.

- Intricate Design Capability: Allows decorative cutouts, ventilation grilles, and artistic detailing.

- Durability: Creates flawless edges that are less prone to wear.

Example: A San Jose homeowner wanted closet shelves with integrated ventilation patterns. Medalco used waterjet cutting to create repeating motifs in wooden panels, both functional and decorative.

Medalco’s Integrated Process

At Medalco, fabrication is never isolated from design or installation. Our process is holistic:

- Consultation and Design: Listening to client needs, visualizing layouts.

- Material Selection: Advising on wood, stone, glass, or hybrid solutions.

- Precision Fabrication: Using CNC and waterjet systems for accuracy.

- Finishing Touches: Custom finishes, hardware, and detailing.

- Installation Prep: Streamlined delivery with pre-drilled and labeled parts.

Example of Workflow Efficiency: In one recent project, Medalco fabricated all closet parts with pre-installed metal inserts. This meant installation required no additional drilling on-site, reducing disruption in the client’s home.

Why Precision Matters in Closets

Unlike freestanding furniture, closets must fit into exact spaces. Even a half-inch misalignment can lead to uneven doors or unusable shelving. This is where Medalco’s fabrication expertise shines.

- CNC routing ensures panels align perfectly.

- Waterjet cutting prevents material waste.

- Mock assemblies in our shop confirm fit.

The result is closets that not only look custom but feel seamless to use.

Conclusion: Why Medalco is the Choice for Custom Closet Fabrication

The fabrication phase of building closets that fit is where vision turns into reality. It is the stage where designs, drawings, and digital plans become physical spaces that enhance everyday living. Precision in fabrication ensures functionality, beauty, and durability, while artistry transforms closets from storage solutions into personal sanctuaries.

At Medalco, we take this process seriously. Our use of waterjet cutting, CNC machining, and custom fabrication techniques allows us to handle wood, stone, glass, and metal with equal mastery. The result is closets that are both practical and luxurious, engineered to last and designed to inspire.

Whether it is a floor-to-ceiling modern wardrobe, a boutique-style walk-in with glass shelving, or a timeless wooden system enriched with stone details, Medalco delivers fabrication that fits your home and lifestyle perfectly.

If you are planning a project and want closets that are more than just storage, reach out to Medalco today. Our team will guide you from concept to installation, making sure every detail aligns with your vision.

Frequently Asked Questions (FAQs)

| 1. What makes Medalco’s closet fabrication different from others? Medalco combines advanced technology like CNC routing and waterjet cutting with traditional craftsmanship. This hybrid approach ensures precision and artistry that most companies cannot match. |

| 2. Can waterjet cutting really improve closet design? Yes. Waterjet cutting allows us to work with stone, glass, metal, and wood, creating custom inlays, ventilation patterns, and decorative cutouts that elevate closets beyond standard cabinetry. |

| 3. What materials are best for custom closets? It depends on your goals. Wood offers warmth and versatility, glass adds elegance and openness, metal ensures strength and modernity, and stone provides luxury accents. Medalco helps clients choose the right combination. |

| 4. How does Medalco ensure closets fit perfectly? We use CNC precision tools to cut components to exact dimensions. Our team also does mock assemblies in-house to verify alignment before installation, reducing on-site adjustments. |

| 5. Is waterjet cutting safe for fragile materials like glass? Absolutely. Unlike saws or lasers, waterjet cutting does not generate heat that could crack or stress glass. It cuts cleanly, even with delicate designs. |

| 6. How long does closet fabrication take? Timelines vary based on size and complexity. A typical custom closet takes 4–8 weeks from design approval to installation. Medalco’s efficient workflow helps shorten turnaround times. |

| 7. Do clients get to see the design before fabrication starts? Yes. Medalco provides detailed 3D renderings and shop drawings. Clients can review layouts, finishes, and materials before production begins. |

| 8. Can Medalco work with architects and interior designers? Yes. We frequently collaborate with architects and designers to integrate closets seamlessly into broader home designs, ensuring harmony in proportion and style. |

| 9. What kind of finishes are available for custom closets? From matte and glossy laminates to natural wood veneers, painted surfaces, and even stone or metal accents, Medalco offers a wide spectrum of finishes. We also provide custom staining and protective coatings. |

| 10. How do I get started with Medalco for my closet project? Simply contact us through our website or visit our San Jose office. We begin with a consultation, followed by design, material selection, fabrication, and professional installation. |

Trusted External Resources

- Insights on trends and best practices in custom cabinetry and wood fabrication.

- Leading source for stone cutting and finishing technologies.

- Covers innovations in metal cutting and forming.

- Authority on glass processing and architectural integration.

- Technical resource on CNC, waterjet, and other precision fabrication tools.