From architectural masterpieces to intricate stone inlays, waterjet technology has quietly become one of the most powerful creative allies for designers, architects, fabricators, and artists alike. At Medalco, we’ve been at the forefront of this innovation—bridging traditional craftsmanship with precision technology to turn ambitious ideas into enduring, tangible art.

This article explores the ways in which waterjet cutting empowers artistic freedom in interior design, sculpture, decor, and beyond. We’ll take a deep dive into the technical capabilities of waterjet, the artistic advantages it brings, and real-world examples of how it transforms visions into form.

The Technology Behind the Art

Waterjet cutting involves using a high-pressure stream of water often mixed with an abrasive substance like garnet—to slice through a wide range of materials. While the process may seem purely industrial at first glance, it is actually one of the most delicate and versatile techniques available.

- Cold Cutting = No Heat Damage: Unlike laser or plasma cutting, waterjet cutting doesn’t generate heat. This “cold” process preserves the integrity of sensitive materials like stone, glass, wood, and composite surfaces.

- Incredible Precision: Waterjets can cut with tolerances as tight as ±0.003 inches. For artists and designers, this translates into razor-sharp details and flawless execution.

- Material Diversity: From marble and granite to metal, plastic, wood, ceramic, and even rubber if you can imagine it, a waterjet can likely cut it.

At Medalco, we operate state-of-the-art CNC waterjet machines in our San Jose facility, pairing them with expert design and fabrication teams. This gives our clients complete creative control with high-end results.

Artistic Freedom in Form and Function

Artistic freedom isn’t just about expression it’s about execution. It’s one thing to sketch a brilliant concept on paper, and another entirely to bring it to life without compromise. Waterjet cutting eliminates many of the traditional constraints of fabrication:

1. Complex Geometries Made Simple

One of the defining features of waterjet technology is its ability to cut intricate shapes that would be either impossible or extremely expensive with traditional methods. Imagine latticework patterns in stone, elaborate floral motifs in brass, or mosaic medallions formed from dozens of interlocking materials.

Medalco Application: Our team frequently uses waterjet cutting for custom medallions, backlit wall panels, and artistic stone layouts that require precision and repeatability. Whether you want Arabic calligraphy carved into marble or a custom Art Deco design in metal, we deliver with finesse.

2. Freedom from Fragility

With heat-based cutting methods, fragile materials like marble or engineered wood risk cracking, chipping, or discoloration. Waterjet cutting eliminates this risk entirely.

This means artists and designers can work with:

- Mixed media, like stone paired with wood or glass, that must be processed carefully.

- Thin veneers that require delicacy.

- Rare stones that can’t be heat-exposed.

3. Large-Scale Precision Artworks

Waterjet machines are also capable of processing large-scale panels with uninterrupted precision. This allows for:

- Massive wall mosaics

- Custom flooring layouts

- Commercial signage and sculptures

For public spaces, hospitality venues, and luxury homes, the ability to scale artistry without losing fidelity is crucial.

Real-World Creative Applications

Let’s look at how artists and designers are pushing boundaries with waterjet technology:

Architectural Features

- Stone wall reliefs with intricate carving-like detail.

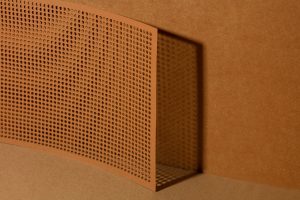

- Latticed privacy screens from metal or composite materials.

- Waterjet-cut metal stair risers with custom artwork.

Interior Design Details

- Flooring inlays that mix stone and wood into cohesive patterns.

- Custom cabinet fronts featuring waterjet-carved motifs.

- Backsplashes and countertops with artistic insets.

Art Installations

- Standalone sculptures in mixed media.

- Wall-mounted installations that combine polished and rough finishes.

- Lighting features where waterjet-cut patterns allow glow-through effects.

At Medalco, our waterjet services have been used in high-end residences, commercial spaces, and religious buildings alike. Each project brings a unique artistic goal and our machines provide the freedom to meet it without compromise.

Going Deeper: Material Considerations

Each material presents different opportunities and challenges when cut artistically. At Medalco, our in-house specialists work closely with clients to select the ideal material, balancing aesthetic goals with performance needs.

Stone (Marble, Granite, Limestone)

- Offers timeless luxury.

- Waterjet allows crisp transitions in patterns and lettering.

- Requires careful handling due to brittleness perfect match for cold cutting.

Metal (Brass, Stainless Steel, Aluminum)

- Ideal for modern and industrial aesthetics.

- Can be backlit for signage or decorative accents.

- Works well in large or thin formats.

Wood and Composite Panels

- Great for warm, tactile applications.

- Waterjet preserves edge fidelity and grain.

- Excellent for decorative screens, cabinetry faces, and wall panels.

Glass and Tile

- Enables intricate mosaic designs.

- Excellent for bathrooms and hospitality installations.

- Waterjet avoids the cracking or thermal stress of other methods

Collaboration Between Designers and Technicians

One of the less discussed but most critical aspects of artistic fabrication is the collaboration between the visionary (the designer or artist) and the technician (the one who operates and interprets the machinery).

At Medalco, we pride ourselves on being more than a production facility we’re creative partners. Our process includes:

- Design Review: We examine CAD or sketch files to ensure technical feasibility while preserving artistic intent.

- Material Consultation: Our material specialists help select the right substrate based on the cut pattern, finish, and installation environment.

- Prototyping: For complex or first-time designs, we offer prototyping runs to test cuts before full fabrication.

- Finishing Services: Post-cut polishing, edging, engraving, and mounting are handled in-house for full control.

This collaborative process ensures that no creative detail is lost in translation.

Designer Spotlight: Waterjet in Boutique Retail Design

One of our favorite collaborations involved a boutique fashion brand in Los Angeles. The interior designer came to Medalco with a vision for luxury wall cladding using reclaimed wood and antique brass. Our waterjet process allowed us to inlay the client’s logo, botanical shapes, and geometric patterns into each wood panel. The results? A retail interior that felt artisanal, bespoke, and brand-rich precisely what the client wanted.

Beyond Cutting: Integrated Fabrication at Medalco

Waterjet cutting is just the beginning. At Medalco, we integrate waterjet work into full-service fabrication:

- Cabinetry and Furniture: Incorporating waterjet-cut inlays, panels, or accents into custom furniture or cabinetry.

- Custom Fireplaces: Stone mantels and surrounds with waterjet detailing.

- Closet and Storage Systems: Decorative paneling and functional elements fused with precision artistry.

- Architectural Millwork: Entryways, door systems, and trims that reflect your artistic vision.

This integration is what sets us apart our waterjet services don’t just end at cutting. We carry the artistic concept through to final form.

Why Waterjet vs. Laser or CNC Routing?

To understand why waterjet offers unique value in artistic applications, it helps to compare it to other cutting technologies:

Laser Cutting

- Excellent for thin metals and plastic.

- Struggles with stone or thick materials.

- Generates heat, which can burn edges or discolor wood.

CNC Routing

- Great for wood and soft materials.

- Less precise for ultra-intricate designs.

- Can cause chipping on harder materials like stone.

Waterjet Cutting

- No heat = no distortion.

- Perfect for hard and fragile materials.

- Ultra-fine detail on a wide range of materials.

- More versatile and material-agnostic.

That’s why for designers working in stone, metal, or composite layers waterjet is the preferred tool.

The Future of Artistic Fabrication

As technology continues to evolve, the applications for waterjet cutting are only expanding:

1. AI-Assisted Design

At Medalco, we are already exploring integrations between AI-based design tools and our waterjet systems. This allows artists to rapidly generate complex geometric patterns that can be instantly prototyped.

2. Eco-Conscious Fabrication

Waterjet cutting generates very little waste compared to subtractive methods. It also allows for recycling of leftover materials, particularly in stone and metal.

3. Hybrid Design Projects

Combining waterjet with CNC and 3D printing opens the door for hybrid designs such as waterjet-cut stone inlays set into 3D-printed resin furniture.

4. Personalized Luxury

More homeowners are seeking unique interiors that reflect their personality. Medalco’s ability to fabricate one-of-a-kind decorative elements makes us ideal for luxury homes that demand exclusivity. Imagine custom stair treads, fireplace mantels, or wall murals personalized to your story.

Why Medalco?

At Medalco, we bring together a rare combination of:

- Artisan Insight: Our roots are in handcrafted cabinetry and architectural features.

- Precision Machinery: We operate high-end CNC waterjet systems with full digital control.

- Full Fabrication: From wood to stone to metal, we handle complex multi-material projects.

- Collaborative Spirit: We see ourselves as partners in your creative journey, not just vendors.

- Innovation-Driven: Our teams embrace the latest in design and production technology.

Whether you’re an interior designer planning a luxury residence, an artist preparing a gallery installation, or a contractor looking for elite finishing touches Medalco provides the tools and talent to get it done.

Final Thoughts: Unleash Creativity with Confidence

Waterjet cutting isn’t just about efficiency or accuracy. It’s about empowerment. It’s a tool that frees designers from the limits of hand tools, traditional methods, and one-size-fits-all solutions. It enables the creation of work that is complex yet clean, bold yet balanced, modern yet timeless.

And when that tool is in the right hands like the expert team at Medalco the results can be nothing short of extraordinary.

- Let your next project break free from fabrication limits. Embrace the art of precision with Medalco’s waterjet expertise.

- Schedule a design consultation today

- Let us help you bring your boldest artistic visions to life

Medalco – Where artistry meets precision.

Want to see our past artistic waterjet projects?

- Browse our gallery on the website

- Follow us on Instagram for real-time project updates

- Drop by our San Jose facility to experience our materials and samples in person

Together, we’ll cut beyond limits and carve out space for your creative freedom.

More About Waterjet Technology and Artistic Applications:

- Waterjet Cutting Basics – Flow Waterjet

- Benefits of Waterjet Cutting – Hypertherm

- Waterjet vs. Laser Cutting – Engineering.com

- Artistic Applications of Waterjet Cutting – WardJet

- Interior Design Trends Involving Waterjet Art – ArchDaily