Contact Us

1752 Junction Ave

San Jose, CA 95112

United States

+1 (650) 520 9326

info@medalsco.com

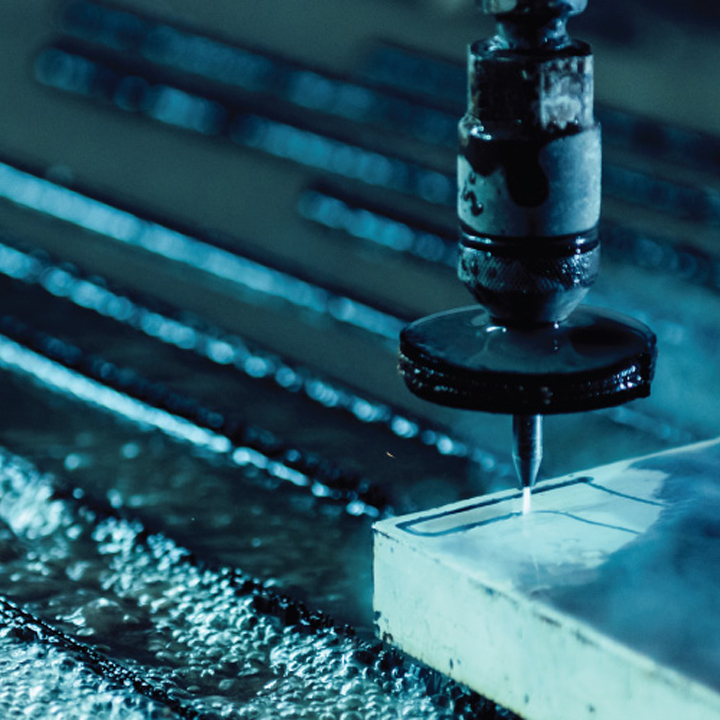

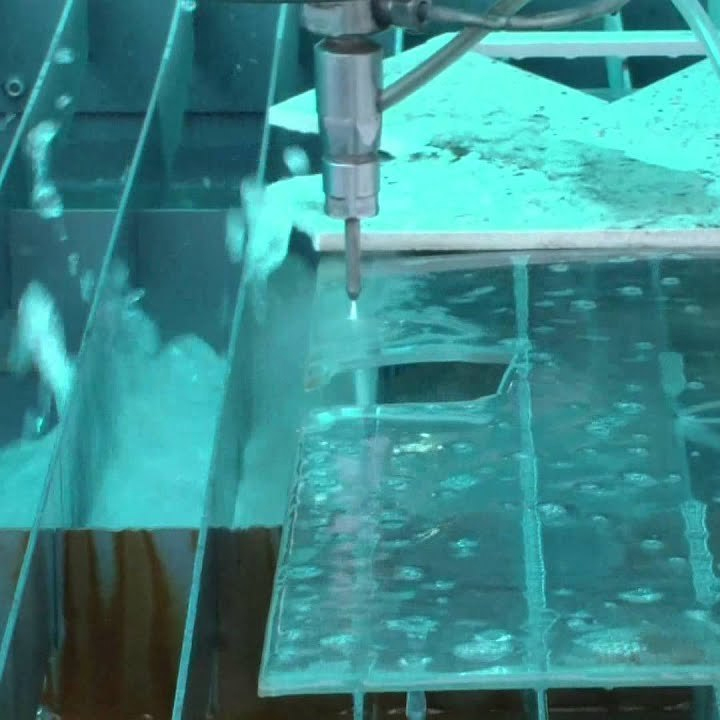

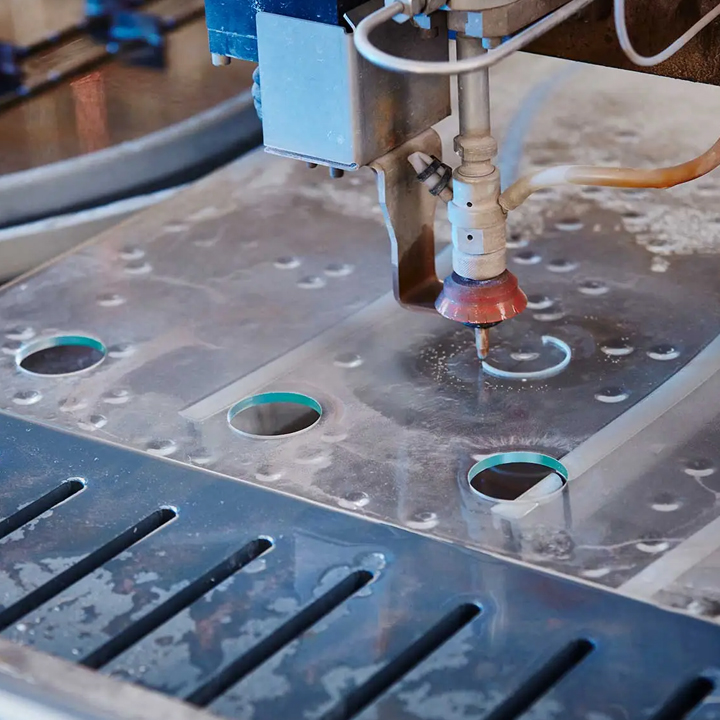

Water jet machining is a cold cutting process that makes it suitable for automotive, medical and aerospace applications where the product can not be affected by heat.Almost every type of cutting is possible, from the use of water jet tables for quick hole drilling to detailed cuts for most industrial applications.

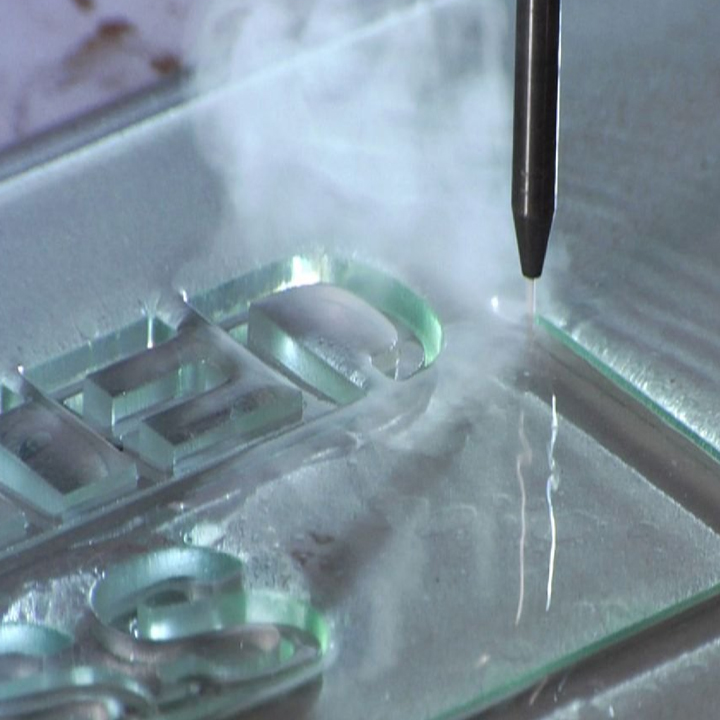

Compared with other fabrication techniques, waterjets can handle just about any material or product that a traditional cutters can. In addition, materials like plastics, rubber, laminated materials, stone, glass, or materials with uneven surfaces can all be handled through waterjet cutting.

Since Waterjet cutting does not generate extreme heat it does not change the properties of metal nor causing any thermal distortion. On the other hand this can occur with laser cutting.

Abrasive Waterjets will typically use garnet as the abrasive material.Garnet is non-reactive that is biologically inert. Waterjets also use much less water than may imagine thanks to its closed-looped system.

Abrasive Waterjets will typically use garnet as the abrasive material.Garnet is non-reactive that is biologically inert. Waterjets also use much less water than may imagine thanks to its closed-looped system.

Waterjets cut with fine sanded-blasted surface finish, which makes it easier to make a high-quality weld for that part. Laser cut material appears to have a rougher, scaly edge which may require additional work and machining to clean up.

Just add your email and hit subscribe to stay informed.

We send our newsletter once a month, and we respect your privacy.