Waterjet cutting is a fabrication process that uses a high-pressure stream of water, often mixed with abrasive particles, to cut through a wide range of materials. The stream moves with computer-guided precision to deliver complex shapes and tight tolerances.

Think of it like a laser cutter but with water instead of heat. And instead of charring or burning the material, it leaves behind smooth, cold edges with no heat distortion.

How Does It Work?

Here’s a simplified breakdown:

- Material Cutting: The pressurized stream slices through material cleanly, with minimal kerf (cut width), no burn marks, and no need for secondary finishing.

- High-Pressure Water Generation: The machine uses a pump to pressurize water up to 60,000–90,000 psi. That’s enough pressure to cut through inches of steel.

- Abrasive Mixing (Optional): For hard materials like stone, metal, and glass, garnet or other abrasives are added to the water stream.

- Precision Cutting Head: A narrow nozzle focuses the stream, and CNC programming guides its path with precisionoften to within fractions of a millimeter.

Materials You Can Cut with Waterjet

Waterjet is one of the most versatile cutting methods available. At Medalco, we use it on:

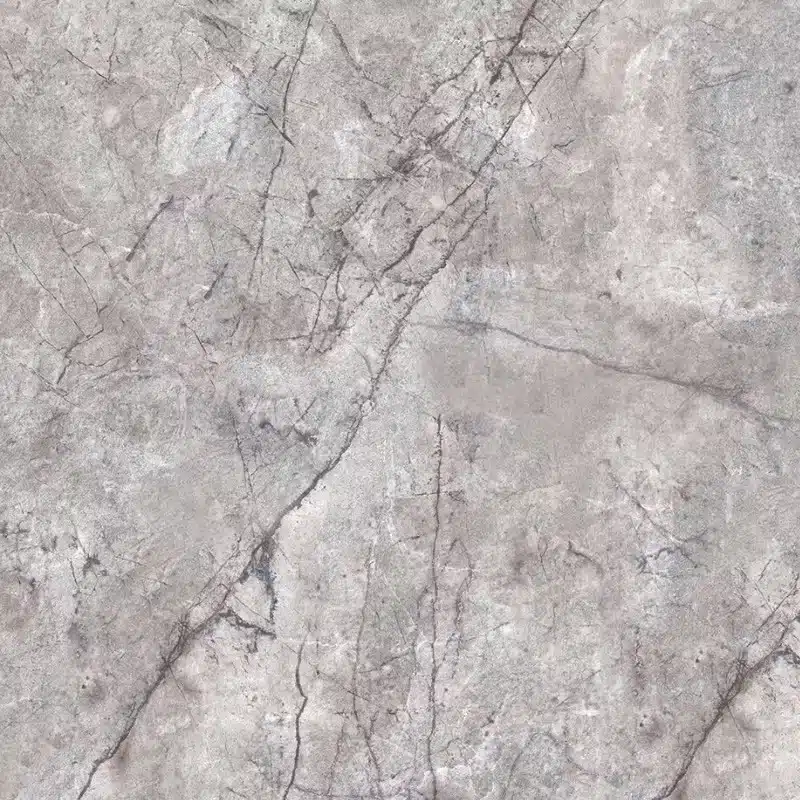

- Natural Stone – granite, marble, quartzite

- Wood – MDF, plywood, hardwood panels

- Metals – aluminum, brass, copper, steel

- Composites – carbon fiber, laminates

- Glass and Ceramics – for decorative applications

- Plastic and Rubber – used in custom gaskets or inserts

Because there’s no heat involved, waterjet cutting won’t warp or alter the properties of the material. That makes it ideal for detailed and structural components alike.

Why It Matters in Modern Design and Fabrication

Now, let’s talk about why this matters—not just to manufacturers but to homeowners, designers, and business owners like you.

1. Precision Like No Other

Waterjet can achieve incredibly detailed cuts, even with materials that are notoriously difficult to shape. Whether it’s a curved stone backsplash or an intricate wood inlay, this technology ensures flawless results.

- Medalco Edge: Our waterjet machines work hand-in-hand with CNC routing to deliver tight tolerances, even in mixed-material projects like wood-and-stone cabinetry.

2. Limitless Creativity

If you can design it, waterjet can likely cut it.

- Custom floor medallions with intricate detail? Check.

- Backsplashes that wrap around columns with curved edges? Absolutely.

- Business logos carved into stone reception desks? Easily done.

With waterjet, complexity doesn’t increase the risk of mistakes—it opens the door for bold design choices.

3. Cleaner, Safer Cuts

Because waterjet doesn’t generate heat, there’s no risk of burning, melting, or releasing toxic fumes from the materials. This makes the process safer for both the environment and the people handling the pieces afterward.

- No charring on wood

- No discoloration on metal

- No micro-fractures in stone

4. Eco-Friendly Process

Waterjet is surprisingly sustainable.

- The process uses minimal material (narrow kerf = less waste)

- There’s no chemical runoff

- Water can often be recycled within the system

5. No Need for Post-Processing

Unlike saws or routers that leave rough or burnt edges, waterjet leaves a smooth, clean finish. That saves time and labor in sanding or polishing—and means you get your finished product faster.

How Medalco Uses Waterjet Cutting

At Medalco, we integrate waterjet cutting into our custom workflows, especially for our work in cabinetry, stone surfaces, and architectural detail. Here’s how it plays into real-world projects:

1. Custom Stone Countertops

We use waterjet to cut sink openings, cooktop recesses, and edge profiles with precision. No chips. No irregular cuts. Just flawless stone.

2. Wood + Stone Cabinets

Creating mixed-material cabinetry is incredibly demanding. Waterjet allows us to align wood and stone components perfectly—whether that’s a curved drawer face or a marble detail set into a wooden frame.

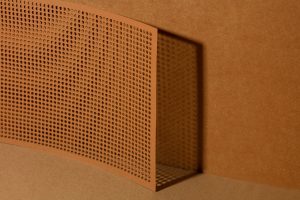

3. Decorative Wall Panels

Want a feature wall with stone that mimics lace or waves? We’ve done it—with waterjet. Even the most intricate design can be made reality.

4. Signage and Branding

For commercial spaces, we create custom-cut logos in wood, metal, or stone that match the interior aesthetic exactly.

4. Keep Handles and Hinges Tight

Loose handles and sagging doors don’t just look sloppy—they lead to long-term wear on the cabinet’s face and interior.

Maintenance Plan:

- Check handles every few months

- Tighten loose screws with a screwdriver

- Lubricate soft-close hinges once a year with silicone spray

Medalco Hardware: We only use premium hinges and pulls with soft-close features, so your cabinets operate smoothly and last longer.

Medalco’s Unique Advantage

Here’s where we stand out:

- Design Support – We work with homeowners, architects, and designers to make sure your vision is achievable—and elevated.

- Full-Service Capability – From digital design to fabrication to installation, we manage the entire process.

- In-House Expertise – Our technicians are trained in both CNC and waterjet technology, which means seamless integration of complex ideas.

- Material Mastery – Whether it’s soft pine or dense granite, we know how to choose the right toolpath and settings to protect your material.

Real Story: A Wine Cellar Like No Other

In a recent project for a luxury home in Northern California, the homeowner wanted a wine cellar door unlike any other—made from walnut with embedded stone vines.

With waterjet, we cut the stone into swirling vine patterns, then inlaid it into the walnut using CNC-routed grooves. The result? A one-of-a-kind entry that turned functional cabinetry into gallery-worthy design.

Is Waterjet Right for Your Project?

If your design involves complex curves, high-end materials, or tight tolerances, waterjet is almost certainly the answer. It’s also ideal when:

- You want to combine materials (wood, stone, metal) seamlessly

- You need precision openings (like in countertops or cabinetry)

- You value finish quality and want to avoid burn marks or chips

- You want to push creative boundaries

At Medalco, we’re happy to guide you through whether waterjet is the right solution—or pair it with other tools like CNC milling or edge banding for even better results.

Let’s Create Something Extraordinary Together

Waterjet isn’t just a tool—it’s a creative enabler. It allows us to say yes when others say “too complex.” It’s part of what makes Medalco more than just a cabinetry company—we’re a precision design and fabrication partner.

Ready to bring your idea to life?