In today’s world of advanced manufacturing and design, precision is everything. Whether you’re crafting a high-end kitchen cabinet, a custom stone countertop, or a metal art piece, the method you choose to cut your materials will directly impact the quality, durability, and beauty of the final product.

Two of the most talked-about technologies in modern fabrication are waterjet cutting and laser cutting. At Medalco, we specialize in custom cabinetry and stonework and frequently use waterjet cutting as part of our production process. But many of our clients ask us: How does waterjet cutting compare to laser cutting? And which is better for my project?

Let’s dive into the core differences, benefits, and best-use scenarios for each method, so you can make an informed decision.

What Is Waterjet Cutting?

Waterjet cutting is a cold cutting process that uses a high-pressure stream of water, sometimes mixed with abrasive particles like garnet, to cut through a wide range of materials. This stream can reach pressures up to 90,000 psi, allowing it to slice through metal, stone, glass, ceramics, and more with incredible precision.

At Medalco, we use waterjet cutting for:

- Custom stone inlays for luxury kitchens and fireplaces

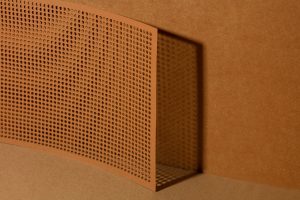

- Decorative panels and wall features

- Precision-cut wood or engineered boards without burning or warping

Why We Love It: It leaves no heat-affected zones (HAZ), which means your material stays true to its original form perfect for delicate designs and natural textures.

What Is Laser Cutting?

Laser cutting uses a focused beam of light to melt, burn, or vaporize material. It’s incredibly fast and accurate, especially for metals and thinner materials. The most common laser types are CO2 and fiber lasers.

Laser cutting is ideal for:

- Metal signage and branding plates

- Thin wood and acrylics

- Complex patterns on metal sheets

While Medalco focuses more on waterjet technology due to our work with stone and mixed materials, we often collaborate with partners who use laser for metal-specific elements.

Waterjet vs. Laser: Head-to-Head Comparison

| Feature | Waterjet Cutting | Laser Cutting |

| Material Flexibility | Cuts virtually any material | Best for metals, plastics, some woods |

| Heat Impact | None (cold process) | Yes (creates heat-affected zones) |

| Thickness Capability | Can cut very thick materials (up to 12″) | Typically best for thin to medium materials |

| Edge Finish | Smooth, no burrs | May need post-processing on thicker cuts |

| Precision | Extremely precise | Very precise, especially in metals |

| Speed | Slower than laser | Generally faster for thin materials |

| Cost Efficiency | Costly for small runs | More efficient for high-volume metal cutting |

When Should You Choose Waterjet Cutting?

At Medalco, waterjet is our go-to solution for custom, high-detail work where the integrity of the material is crucial.

Ideal for:

- Natural Stone and Porcelain: Because waterjet doesn’t generate heat, it avoids cracking or discoloration—perfect for high-end countertops and fireplace surrounds.

- Wood Composites and Veneers: Laser can burn or char wood, but waterjet leaves clean, cool edges.

- Glass and Ceramic: Waterjet can cut through these brittle materials without risk of shattering.

- Artistic Inlays: Waterjet allows us to cut intricate patterns that fit together like puzzle pieces, great for custom flooring, wall art, and cabinetry accents.

Client Story: In a luxury kitchen remodel in Walnut Creek, our client wanted a medallion inlay in the center of a travertine floor. With waterjet, we cut delicate floral shapes in multiple stones and assembled them seamlessly—no fractures, no burned edges, just perfect elegance.

When Is Laser Cutting Better?

Laser cutting has its own strengths, especially for jobs that require speed and tight tolerances on thin materials.

Ideal for:

- High-volume metal components

- Detailed etching or engraving on metal surfaces

- Projects with tight deadlines and lower material complexity

If you need a custom stainless steel nameplate or signage with intricate typography, laser is often the better choice.

The Environmental Side of Things

Waterjet cutting uses water and natural abrasive materials, making it relatively eco-friendly—especially when the water is recycled in a closed-loop system.

Laser cutting may produce fumes or require ventilation depending on the material. It consumes more electricity per cut, but with less waste overall in high-volume operations.

Why Medalco Prioritizes Waterjet Technology

For a company like Medalco, which thrives on combining wood, stone, and aesthetic design, waterjet cutting offers unmatched versatility.

- Multi-Material Use: We can cut wood, stone, and composites with the same machine, reducing production complexity.

- Clean Lines: Our designers love the crisp, cool edges that preserve a material’s natural beauty.

- Customization: From one-off artistic patterns to functional pieces, waterjet adapts to your vision.

With CNC integration and high-pressure waterjet systems, our fabrication shop in San Jose creates architectural elements and cabinetry features that are both technically precise and visually stunning.

Final Thoughts: It’s Not a Contest, It’s a Choice

If your design involves complex curves, high-end materials, or tight tolerances, waterjet is almost certainly the answer. It’s also ideal when:

- You want to combine materials (wood, stone, metal) seamlessly

- You need precision openings (like in countertops or cabinetry)

- You value finish quality and want to avoid burn marks or chips

- You want to push creative boundaries

At Medalco, we’re happy to guide you through whether waterjet is the right solution—or pair it with other tools like CNC milling or edge banding for even better results.

Let’s Create Something Extraordinary Together

Choosing between waterjet and laser cutting isn’t about which is better overall it’s about what your project demands.If you’re working with metal and want speed and detail, laser is your friend. If you’re dealing with mixed materials, need thickness variety, or want to preserve natural textures, waterjet is unbeatable.

At Medalco, we offer more than just tools—we offer design insight, technical mastery, and collaboration. Whether you know exactly what you want or are exploring possibilities, we’ll guide you toward the right fabrication method to bring your project to life.

Let’s Build Beautiful Things Together

Contact us for a custom consultation, and see how Medalco’s precision cutting, expert cabinetry, and artistic design come together to elevate your space.