29 Frequently Asked Questions About Waterjet Cutting:

1- What Is Waterjet Cutting?

Waterjet cutting is a fascinating process where a super high-pressure stream of water, sometimes mixed with abrasive particles, slices through materials with incredible precision. Imagine a fire hose on steroids but laser-focused into a tiny, powerful jet that can cut metals, stones, glass, and more without melting or distorting the material. This cold cutting technique is revolutionizing how we shape everything from aerospace components to decorative stone.

2- The Basics Explained

At its core, waterjet cutting uses ultra-high-pressure water (typically between 30,000 and 60,000 psi) pushed through a small nozzle to create a cutting jet. When abrasives like garnet are added, the jet gains extra power to cut harder materials. Because no heat is involved, the material keeps its original structural integrity, unlike heat-based cutting methods such as lasers or plasma.

3- History and Evolution of Waterjet Cutting

Waterjet cutting began in the 1950s for cutting softer materials but evolved drastically in the 1980s when abrasive particles were introduced. Since then, advancements in pump technology and control systems have made it an industry favorite for precision cutting, expanding its use across many materials and industries. It’s like the quiet, hardworking hero of modern manufacturing.

4- How Does Waterjet Cutting Work?

The magic lies in turning water into a sharp cutting tool by forcing it through a tiny orifice at ultra-high pressures. Adding abrasive garnet particles turns it into a supercharged sandblaster that cuts through the toughest materials. The mixture zooms out at velocities up to 900 meters per second—fast enough to slice cleanly without creating heat or mechanical stress.

5- Pure Waterjet Cutting vs Abrasive Waterjet Cutting

Pure waterjet cutting uses just water and is great for soft materials like rubber or foam. Abrasive waterjet cutting adds hard particles to tackle metals, stone, ceramics, and composites. Think of pure waterjet as a gentle but precise scalpel, and abrasive waterjet as a powered chainsaw—but way more refined. Choosing between them depends on your material and finish needs

6- What Materials Can Be Cut Using Waterjet Cutting?

The versatility of waterjet cutting is impressive. It works on metals like steel, aluminum, and titanium, stones like granite and marble, glass, ceramics, plastics, composites, and even delicate items like foam or food products. This flexibility means it’s used everywhere—from industrial manufacturing to artisanal crafts and even gourmet kitchens.

7- Cutting Food and Specialty Materials

Did you know waterjet cutting is used to portion food items like frozen meats and vegetables? Since the process doesn’t generate heat or chemical residues, it keeps food safe and fresh. It’s also used in medical device manufacturing and intricate artistic projects where precision and material integrity are key.

8- What Are the Main Advantages of Waterjet Cutting?

Waterjet cutting offers numerous benefits: no heat damage, extremely high precision, ability to cut complex shapes, minimal waste due to a very thin kerf (cut width), and an environmentally friendly footprint. It’s like having a Swiss Army knife in your workshop—versatile, precise, and clean.

9- Precision and No Heat-Affected Zones

Because it’s a cold cutting method, waterjet cutting prevents warping, cracking, or weakening materials. This means the parts come out ready for use without costly post-processing, saving time and money. It’s a precision artist, crafting parts with clean edges and exact dimensions.

10- Eco-Friendly and Waste Reduction

Waterjet cutting uses water and natural abrasives, which can be recycled and filtered. It produces less dust, smoke, or toxic fumes compared to laser or plasma cutting, making it a greener choice. Plus, its narrow kerf means less raw material is wasted—good news for both budgets and the planet.

11- Versatility Across Industries

From aerospace parts to stone decor, from automotive gaskets to food portions, waterjet cutting adapts to countless applications. Its ability to handle a broad range of materials without switching tools saves time and boosts productivity, making it a favorite in diverse fields.

12- What Are the Limitations of Waterjet Cutting?

Despite its many perks, waterjet cutting has limits. It’s slower than laser for thin materials, can struggle with very thick or ultra-hard metals, and nozzle wear requires routine maintenance. Plus, very delicate thin materials might deform without special handling. Knowing these constraints helps you choose the best cutting method for your project.

13- Thickness, Speed, and Material Constraints

Typically, waterjet cutting handles materials up to about 6 inches thick efficiently. Beyond that, cutting becomes slow and expensive. Speed also depends on material hardness and complexity of design. Planning and consulting with experts ensure you get the best results within reasonable timelines.

14- Machine Maintenance and Operational Costs

The abrasive nature of the process wears down nozzles and pumps, so regular maintenance is necessary. While initial costs can be higher than some alternatives, the savings in quality, reduced finishing, and versatility often balance it out.

15- How to Prepare Your Designs for Waterjet Cutting?

Good preparation is key. Vector CAD files like DXF or DWG work best. Designs should avoid overlapping lines or open paths and must consider kerf width (usually 0.04 to 0.1 mm) to ensure parts come out the right size. Collaborating with your waterjet cutting service early can prevent costly mistakes.

16- File Types and Design Best Practices

Use closed vector paths and keep design elements simple but precise. Avoid tiny internal details that could break or be lost. Ensure your design fits the material sheet size to optimize cutting layouts and reduce waste.

17- Accounting for Kerf and Tolerances

The kerf is the width the jet removes. You need to account for this when designing so parts fit perfectly post-cut. Typical tolerances for waterjet cutting range from ±0.001 to ±0.005 inches depending on material and machine quality. Communicating your tolerance needs helps optimize outcomes.

18- What Are the Safety Considerations in Waterjet Cutting?

Waterjet cutting uses extremely high pressures, so safety is a top priority. Operators must wear protective gear, including eye and ear protection, and machines should have emergency shut-offs and safety guards. Training and adherence to protocols minimize risks of injury or equipment damage.

19- Proper Handling and Operator Safety

Never bypass safety features or come in contact with the jet stream. Keep the workspace clean and dry to prevent slips. Proper handling of abrasives and disposal of waste water is also important for environmental and workplace safety.

20- How Does Waterjet Cutting Compare to Other Cutting Methods?

Comparing cutting methods depends on your goals. Waterjets offer unmatched versatility and cold cutting, lasers offer speed and precision on thin metals, plasma cutting is great for thicker metals but less precise, and mechanical cutting can be cost-effective but less flexible. Knowing the trade-offs helps you choose the perfect fit.

21- Waterjet vs Laser Cutting

Laser cutting is faster on thin metals but introduces heat, which can warp or weaken materials. Waterjet cutting works on thicker, heat-sensitive materials but generally cuts slower. Waterjet edges often require less finishing. Both excel in different niches.

22- Waterjet vs Plasma and Mechanical Cutting

Plasma cutting is faster on thick steel but rougher and less precise. Mechanical cutting methods like sawing or milling can’t match the versatility or clean edge of waterjets. Waterjets stand out when you need accuracy and material integrity without heat damage.

23- What Industries Benefit Most from Waterjet Cutting?

Aerospace, automotive, architecture, stone fabrication, food processing, and medical device manufacturing are just a few sectors that rely heavily on waterjet cutting. Its ability to cut diverse materials precisely and cleanly is invaluable across these industries.

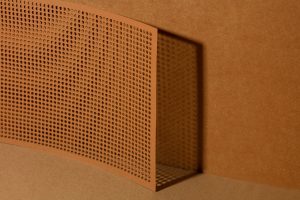

24- Aerospace, Automotive, Architecture, and Art

In aerospace, waterjet cutting produces complex components without damaging metals. Automotive uses it for prototype parts and custom detailing. Architects and artists love it for precision cutting of stone, glass, and metal to create stunning designs.

25- What Does Waterjet Cutting Cost?

Costs depend on material, thickness, design complexity, and machine time. Though waterjet cutting isn’t always the cheapest, its precision reduces waste and finishing costs, often making it more economical overall. Getting quotes from experienced providers like Medalco helps you budget accurately.

26- Pricing Factors and Cost Efficiency

Factors influencing cost include abrasive use, setup time, labor, and machine wear. Complex or tight-tolerance designs increase costs. However, the ability to cut multiple materials with one machine adds value and efficiency.

27- How Long Does Waterjet Cutting Take?

Time depends on design complexity, material type, and thickness. Simple parts can be cut quickly, while intricate or thick materials take longer. Waterjet cutting may be slower than lasers for thin parts but saves time by reducing finishing work.

28- Factors Affecting Cutting Time

The harder and thicker the material, the slower the cut. Complex contours or multiple parts also extend time. Skilled operators optimize paths to reduce cutting duration.

29- Can Waterjet Cutting Be Used for Prototyping and Custom Jobs?

Absolutely! Waterjet cutting is ideal for prototyping because it requires no tooling changes and can handle custom designs in various materials quickly and accurately. This makes it a favorite for startups and industries testing new products.

How Medalco Provides Expert Waterjet Cutting Services

Medalco stands out by combining cutting-edge waterjet machines with skilled operators who understand material nuances. We specialize in everything from custom cabinetry and stone décor to industrial metal parts. Our attention to detail and customer-focused approach ensure you get top-notch results, every time.

Technology, Experience, and Customer Focus

Our advanced equipment allows us to cut complex designs with razor-sharp precision while minimizing waste. Coupled with years of experience, we guide customers through design preparation and material selection, making the entire process smooth and satisfying. We pride ourselves on quality, affordability, and timely delivery.

Conclusion

Waterjet cutting is truly a versatile and powerful technology that’s reshaping manufacturing, design, and even food processing. Its ability to deliver precise, clean cuts across a huge range of materials, without heat damage or environmental harm, makes it a standout choice for businesses and creatives alike. If you want to bring your ideas to life with precision and care, waterjet cutting is a tool you definitely want on your side. And when you’re ready, Medalco is here to provide expert, reliable waterjet cutting services tailored to your needs.

FAQs

| 1. Is waterjet cutting safe for all materials? Waterjet cutting is safe for most materials, especially heat-sensitive ones, but extremely thin or fragile materials require special handling to avoid damage. |

| 2. How does waterjet cutting affect the environment? It’s one of the greenest cutting technologies, using recyclable water and non-toxic abrasives, producing minimal waste and no harmful gases. |

| 3. Can I submit my own design files for waterjet cutting? Yes, providing clean vector CAD files like DXF or DWG is best. Working with your cutting service to optimize the design helps ensure a perfect cut. |

| 4. What’s the typical turnaround time for waterjet cutting jobs? It varies by complexity and material but often ranges from a few hours for simple jobs to a few days for complex or large projects. |

| 5. Why choose Medalco for waterjet cutting? Medalco has advanced technology and experienced operators. |

More About Waterjet Technology and Artistic Applications:

- Waterjet Cutting Safety: TechniWaterjet

- Waterjet Cutting Applications: TechniWaterjet

- Waterjet Cutter Costs and Prices: TechniWaterjet

- Waterjet Cutting Explained: Fractory

- Waterjet FAQs: omax.com