Waterjet Cutting Service

Where Function Meets Visual Harmony

Waterjet cutting is truly a versatile and powerful technology that’s reshaping manufacturing, design, and even food processing. Its ability to deliver precise, clean cuts across a huge range of materials, without heat damage or environmental harm, makes it a standout choice for businesses and creatives alike. If you want to bring your ideas to life with precision and care, waterjet cutting is a tool you definitely want on your side. And when you’re ready, Medalco is here to provide expert, reliable waterjet cutting services tailored to your needs.

- Is Waterjet Safe for all Materials?

Waterjet cutting is safe for most materials, especially heat-sensitive ones, but extremely thin or fragile materials require special handling to avoid damage.

- How dose waterjet cutting affect the environment?

It’s one of the greenest cutting technologies, using recyclable water and non-toxic abrasives, producing minimal waste and no harmful gases.

- How does Waterjet cutting work?

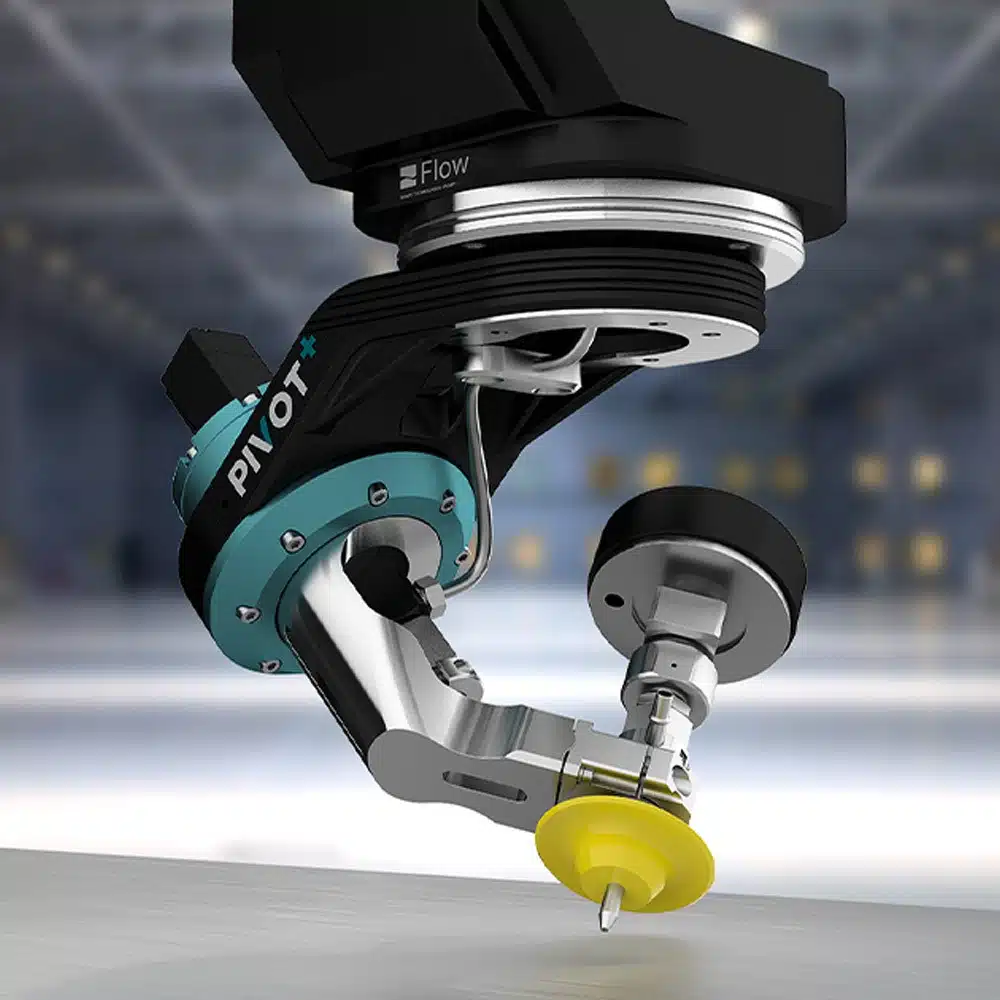

The magic lies in turning water into a sharp cutting tool by forcing it through a tiny orifice at ultra-high pressures. Adding abrasive garnet particles turns it into a supercharged sandblaster that cuts through the toughest materials. The mixture zooms out at velocities up to 900 meters per second—fast enough to slice cleanly without creating heat or mechanical stress.

- What Materials Can Be Cut Using Waterjet Cutting?

The versatility of waterjet cutting is impressive. It works on metals like steel, aluminum, and titanium, stones like granite and marble, glass, ceramics, plastics, composites, and even delicate items like foam or food products. This flexibility means it’s used everywhere from industrial manufacturing to artisanal crafts and even gourmet kitchens.

- What Are the Main Advantages of Waterjet Cutting?

Waterjet cutting offers numerous benefits: no heat damage, extremely high precision, ability to cut complex shapes, minimal waste due to a very thin kerf (cut width), and an environmentally friendly footprint. It’s like having a Swiss Army knife in your workshop versatile, precise, and clean.

Learn

Waterjet cutting is truly a versatile and powerful technology that’s reshaping manufacturing, design, and even food processing. Its ability to deliver precise, clean cuts across a huge range of materials, without heat damage or environmental harm, makes it a standout choice for businesses and creatives alike. If you want to bring your ideas to life with precision and care, waterjet cutting is a tool you definitely want on your side. And when you’re ready, Medalco is here to provide expert, reliable waterjet cutting services tailored to your needs.

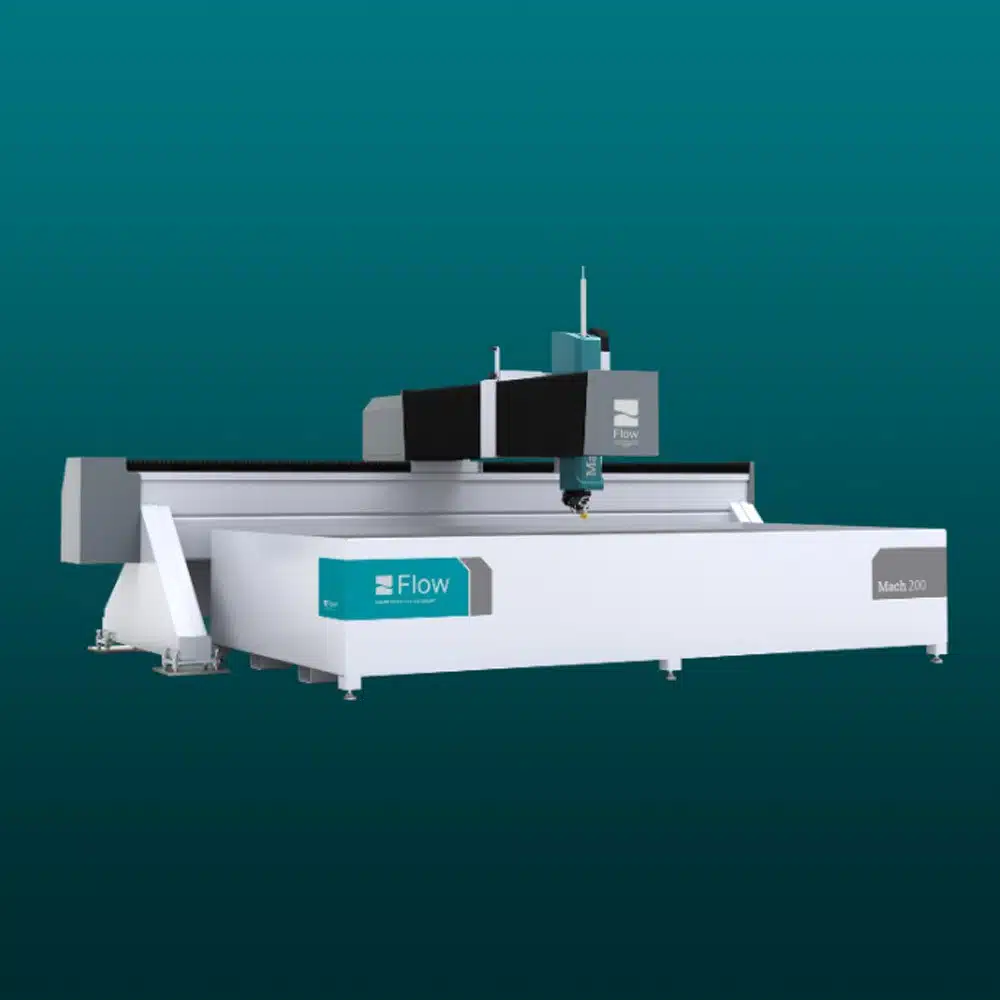

Technology, Experience, and Customer Focus

Our advanced equipment allows us to cut complex designs with razor-sharp precision while minimizing waste. Coupled with years of experience, we guide customers through design preparation and material selection, making the entire process smooth and satisfying. We pride ourselves on quality, affordability, and timely delivery.

- Is waterjet cutting safe for all materials? Waterjet cutting is safe for most materials, especially heat-sensitive ones, but extremely thin or fragile materials require special handling to avoid damage.

- How does waterjet cutting affect the environment? It’s one of the greenest cutting technologies, using recyclable water and non-toxic abrasives, producing minimal waste and no harmful gases.

- Can I submit my own design files for waterjet cutting? Yes, providing clean vector CAD files like DXF or DWG is best. Working with your cutting service to optimize the design helps ensure a perfect cut.

- What’s the typical turnaround time for waterjet cutting jobs? It varies by complexity and material but often ranges from a few hours for simple jobs to a few days for complex or large projects.

- Why choose Medalco for waterjet cutting? Medalco offers advanced technology, experienced operators,