10 Powerful Ways Waterjet Cutting Transforms Cabinet Detailing

Introduction: Why Cabinet Detailing Matters More Than Ever

In today’s competitive design landscape, precision is non-negotiable. Clients expect perfection down to the millimeter, clean lines, tight joints, artistic flourishes, and integrated technology. This is where traditional woodworking tools often fall short. The old-school router or saw, while still useful, just can’t match the finesse and versatility that today’s designers demand.

So what’s the secret weapon?

Waterjet cutting.

From perfect circles in stone inlays to intricate filigree on wood panels, waterjet technology brings a new level of craftsmanship to cabinet making. Let’s dive into how this advanced cutting method is revolutionizing cabinet detailing—one jet of water at a time.

Understanding Waterjet Cutting Technology

What is Waterjet Cutting?

Waterjet cutting is a process that uses a high-pressure stream of water, often mixed with an abrasive substance, to slice through a wide range of materials. Unlike saws or lasers, it doesn’t generate heat, meaning the material’s structure isn’t altered during cutting.

The stream can be as fine as a human hair but powerful enough to slice through stone, wood, metal, and even glass. This makes it an ideal tool for detailed, custom work where both aesthetics and structural integrity matter.

How Waterjet Cutting Works

Imagine a pressure washer, but supercharged. Waterjet machines pressurize water up to 90,000 PSI and force it through a tiny nozzle. For harder materials like granite or steel, fine garnet particles are added to the stream to enhance cutting power. This allows the machine to execute razor-sharp designs based on a digital blueprint.

Waterjet vs. Traditional Methods

| Feature | Waterjet Cutting | Traditional Cutting |

|---|---|---|

| Heat generation | None | High heat (burn risk, warping) |

| Precision | Up to ±0.003 inches | Generally ±0.125 inches or higher |

| Material compatibility | Wood, metal, stone, composites, glass | Mostly wood and soft materials |

| Environmental impact | Low (no toxic fumes, minimal waste) | Higher (dust, sawdust, and fumes) |

| Design complexity | Extremely high | Limited by tool size and flexibility |

1. Ultra-Precise Cuts for Intricate Designs

Complex Corners? No Problem

One of the main advantages of waterjet cutting is its unparalleled precision. With the ability to cut down to a fraction of a millimeter, waterjets can handle detailed work that’s almost impossible with manual tools. This includes tight corners, rounded edges, thin inlays, and even filigree patterns.

Designers no longer need to compromise between ambition and practicality, if you can dream it, a waterjet can cut it.

Minimal Material Waste

The accuracy of waterjet cutting also reduces material waste. When you’re working with premium materials like exotic hardwoods or natural stone, every inch matters. Less waste means more sustainable practices and lower material costs over time.

2. Seamless Integration with Custom Cabinet Designs

From Blueprint to Beauty

Have a CAD design you want to bring to life? Waterjet cutting allows direct translation of digital designs into physical components. Whether it’s a unique drawer front, a laser-like vent design, or a curved cabinet panel, waterjet ensures the final piece looks exactly like the render.

This means architects, interior designers, and homeowners can expect total accuracy between concept and delivery, an essential in high-end or commercial cabinetry

3. Compatibility with Diverse Materials

Not Just Wood

Waterjet isn’t limited to just plywood and MDF. It cuts through a wide variety of materials used in cabinetry:

- Composites like MDF and HDF

- Solid wood

- Veneers

- Plywood

Stone, Metal, and Composite Integration

Want a marble inlay on a cabinet door? No problem. Fancy a brushed steel strip running along the drawer face? Waterjet can cut it. This opens up design possibilities by allowing cabinetmakers to incorporate hard-to-machine materials into their builds without needing separate tools or machines.

4. No Heat = No Warping

Cold-Cut Advantage

Traditional cutting methods, especially lasers, generate heat, which can scorch wood, melt laminates, or warp thin panels. Waterjet cutting is a cold-cutting process, so the integrity of the material remains intact. There’s no charring, discoloration, or distortion.

This is especially useful when working with laminated materials or combining elements like metal and wood in a single panel. You get clean, sharp edges every time, no sanding required.

5. Perfect Fit for Fixtures and Inserts

Precision for Handles, Hinges, and Tech Add-ons

Think about all the things you insert into cabinetry: LED lights, power outlets, hidden charging docks, smart locks, hinges, knobs, pulls, and even built-in speakers. Each of these requires ultra-precise cutouts.

Waterjet makes it easy to create openings that fit perfectly, right out of the machine. There’s no guesswork, no drilling, and no touch-ups. That means better results in less time.

6. Complex Inlays Made Easy

Artistry Without the Hassle

Inlay work, whether with metal, stone, or even contrasting wood, has traditionally been a painstaking process involving chisels, routers, or CNC routing. But with waterjet technology, the tedious becomes effortless. It allows you to cut both the base and inlay pieces with such high precision that they fit together like puzzle pieces, no gaps, no filler, no sanding.

Want a custom company logo embedded into a conference room cabinet door? Done. Looking to impress a client with a floral stone-and-wood inlay on a luxury wardrobe? Waterjet makes it doable, and profitable.

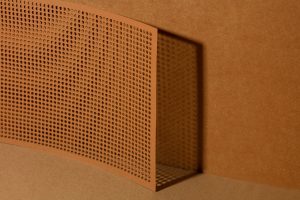

7. Decorative Accents and Artistic Flourishes

From Geometric to Organic Designs

Waterjet opens the door to detail-rich accentsو think fretwork, lattice designs, curved motifs, or even Arabic calligraphy patterns on cabinet panels. Traditional carving would take hours and introduce human error, but a waterjet completes the job in minutes with surgical accuracy.

Modern Meets Traditional

What’s powerful is that you can recreate historic styles (like Rococo or Persian motifs) with modern materials like engineered wood or aluminum, adding old-world charm to contemporary interiors. It’s a designer’s playground.

8. Superior Edge Quality Means Less Finishing

No Burn Marks or Burrs

Have you ever seen laser-cut MDF with those charred edges that need hours of sanding or painting? That’s never the case with waterjet. The cuts are clean and ready for finishing right out of the machine. Edges remain smooth, sharp, and true to form.

This saves a ton of time in post-processing, reducing production costs and man-hours.

9. Efficient Prototyping and Rapid Design Testing

Fast Iterations Without Setup Hassles

For cabinet makers who design on the fly or produce custom builds, waterjet’s digital nature is a dream. Need to test three handle placements on a drawer face? Want to experiment with different radius curves for an arched cabinet top? Just tweak the CAD file and rerun the job.

You’re not reconfiguring machines or burning through material. This flexibility is invaluable when clients demand changes during the design phase.

10. Scalable Customization for Batch Orders

Mass Customization, Not Just Mass Production

One of the biggest challenges in cabinetry is combining scale with individuality. But waterjet systems shine in exactly this scenario. You can run 100 cabinet doors with unique personalization, different names, logos, or layouts, all in one batch.

It’s perfect for hospitality, real estate developers, or luxury builders who need to offer bespoke elements at volume.

Waterjet Technology at Medalco: Where Craft Meets Innovation

At Medalco, we’ve invested heavily in high-end waterjet machinery because we believe details matter. Whether we’re crafting custom kitchen cabinetry, luxury wardrobes, or artistic wood-stone furniture panels, our waterjet cutters give us an edge, literally and figuratively.

Why Choose Medalco’s Waterjet Cabinet Detailing?

- Full design-to-production capabilities: From CAD to installation.

- Unmatched precision: Ideal for unique requests and intricate projects.

- Multi-material mastery: Wood, stone, aluminum, glass, we cut them all.

- Located in San Jose, CA: Proudly serving Northern California with quick turnaround times

When your project demands more than just “good enough,” we deliver from precision to perfection.

Conclusion: Cabinets That Tell a Story

Cabinetry isn’t just storage, it’s storytelling. And with waterjet cutting, that story can be as intricate, elegant, or bold as you like. Whether you’re adding stone inlays, curving wooden panels, or embedding technology, this method brings dreams to life with pixel-perfect accuracy.

No more compromises. No more limitations. Just pure design freedom.

So the next time you envision a cabinet that speaks volumes in its silence, remember, waterjet is the whisper of precision behind its perfection.

10 FAQs About Waterjet and Cabinet Detailing

| 1. What is waterjet cutting used for in cabinetry? It’s used to make precise cuts for decorative details, inlays, fixture openings, and more. |

| 2. Does waterjet cutting damage wood? No. Since it’s a cold process, there’s no burning, warping, or cracking. |

| 3. Can waterjet cut through stone for cabinet detailing? Yes. Waterjet can slice through marble, granite, quartz, and more—perfect for inlays. |

| 4. How does waterjet compare to laser cutting? Waterjet doesn’t use heat, so it doesn’t cause edge burn or discoloration, unlike lasers. |

| 5. Is waterjet cutting suitable for mass production? Yes, especially for semi-custom or personalized designs at scale. |

| 6. What’s the maximum thickness a waterjet can cut? Depending on the material, up to several inches thick—perfect for multi-layer cabinetry. |

| 7. Is waterjet accurate enough for joinery? Absolutely. Tolerances are within ±0.003 inches. |

| 8. Can I use waterjet to make my brand logo on cabinets? Definitely. Logos, text, and patterns can be cleanly embedded with perfect alignment. |

| 9. How fast is waterjet compared to manual methods? It drastically reduces cutting and finishing time—often hours faster per unit. |

| 10. Why should I choose Medalco for custom cabinetry? We blend cutting-edge waterjet tech with years of design and fabrication expertise to deliver unmatched quality and beauty. |

More About Waterjet Technology and Artistic Applications:

- advantages of waterjet cutting

- waterjet’s material versatility

- waterjet boosting sustainable construction

- waterjet in architectural and decorative stone cutting

- waterjet versus laser, plasma, and mechanical cutting