Stone has been a foundational material in architecture and design for centuries. From intricate carvings in historical landmarks to sleek, modern countertops, stone fabrication has transformed raw materials into functional and artistic masterpieces. As technology advances, traditional methods are evolving, allowing for unprecedented precision and creative possibilities. One of the most revolutionary developments in this field is waterjet cutting, a technology that has reshaped the way fabricators work with natural and engineered stone.

This blog explores the science, advantages, applications, and future of stone fabrication, with a deep dive into the impact of waterjet cutting in modern craftsmanship.

Understanding Stone Fabrication: The Journey from Raw Material to Masterpiece

Step 1: Selecting the Right Material

Fabrication begins with selecting the right stone for the project. Depending on the purpose and design aesthetic, options include:

- Natural Stones: Marble, granite, travertine, onyx, and quartzite—renowned for their durability and timeless beauty.

- Engineered Stones: Quartz, sintered stone, and porcelain—offering consistency in pattern and enhanced strength.

Step 2: Cutting and Shaping

Stone must be precisely cut and shaped according to project specifications. Traditionally, mechanical saws were used, but newer technologies allow cleaner cuts and intricate detailing.

Step 3: Finishing and Polishing

After the stone is shaped, finishing techniques refine its edges and surface, ensuring smooth textures, enhanced durability, and an elegant appearance.

While conventional methods have served artisans well, waterjet cutting has transformed stone fabrication, offering a level of precision that was once impossible.

Waterjet Cutting: The Technology Behind Precision Fabrication

How Does Waterjet Cutting Work?

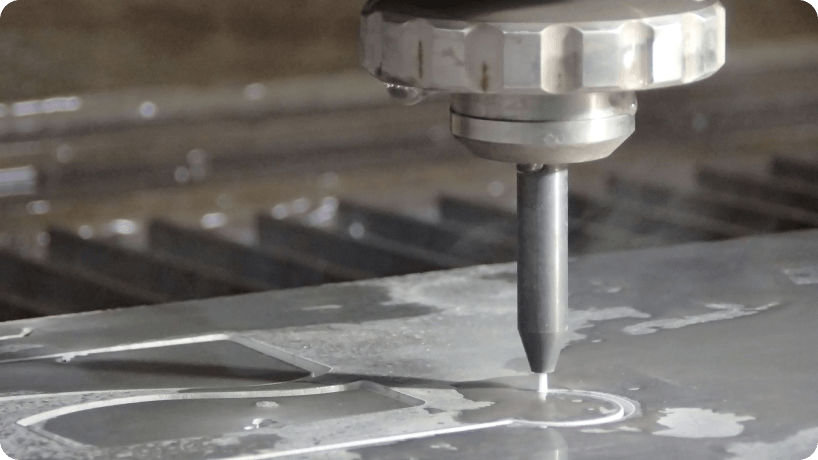

Waterjet cutting utilizes a high-pressure stream of water, often mixed with abrasive particles, to slice through stone without heat or mechanical force. This process ensures clean edges, intricate patterns, and minimal material waste.

The Advantages of Waterjet Technology in Stone Fabrication

🔹 Unrivaled Precision – Allows fabricators to create complex designs, sharp angles, and delicate curves with ease.

🔹 No Heat Damage – Unlike laser cutting or grinding methods, waterjet cutting prevents thermal stress, eliminating cracks or discoloration.

🔹 Versatility Across Materials – Capable of cutting marble, granite, quartz, porcelain, metal, glass, and more.

🔹 Eco-Friendly & Sustainable – Reduces stone waste and optimizes material usage, making it a greener alternative.

Applications of Waterjet Cutting in Luxury Stone Craftsmanship

Engineered & Composite StonesWaterjet technology unlocks new creative possibilities for architects, designers, and fabricators, allowing them to push boundaries and create stunning installations.

✅ Intricate Inlays & Patterns – Ideal for custom flooring designs, decorative backsplashes, and artistic wall features.

✅ Seamless Waterfall Edges – Precision-cut stone for kitchens and vanities, creating dramatic yet functional designs.

✅ Embedded Lighting in Stone – Waterjet-cut grooves for integrated lighting systems, adding an elegant touch to interiors.

✅ Custom Sculptural Work – Perfect for artistic stone installations, allowing for complex geometrical cuts and creative expression.

The Future of Fabricated Stone: Pushing Boundaries with Technology

The evolution of digital fabrication and AI-assisted design continues to advance stone craftsmanship. With innovations such as 3D modeling, robotic automation, and CNC-enhanced precision, the possibilities are limitless.

Waterjet cutting represents a shift toward high-tech, sustainable craftsmanship, ensuring that fabrication remains an art form while embracing the latest advancements in engineering. As luxury design evolves, fabricators equipped with cutting-edge tools will lead the way, crafting breathtaking stonework with unparalleled precision.

Conclusion: Innovation Meets Craftsmanship

Stone fabrication has long been a fusion of tradition and technology, evolving from ancient chiseling techniques to waterjet precision that defines modern luxury craftsmanship. As the industry continues to push boundaries, fabricators who master advanced cutting technologies will not only refine their skill but also redefine luxury design itself.

Whether crafting an exquisite marble countertop, a sculpted stone masterpiece, or an intricately embedded lighting feature, the future of stone fabrication lies in the power of precision, creativity, and technology.