Enter waterjet cutting a technology that has transformed how designers and manufacturers approach stonework. At Medalco, we’ve embraced this innovative method not only to push the boundaries of what’s possible in design but also to deliver unmatched precision and efficiency to our clients.

In this article, we’ll explore how waterjet cutting enhances accuracy and efficiency in stone design, and why this matters for builders, interior designers, and homeowners who want stunning results without compromise.

What Is Waterjet Cutting?

Waterjet cutting is a process that uses a high-pressure stream of wate sometimes mixed with abrasive particles—to slice through various materials, including natural stone. Unlike mechanical cutting tools, a waterjet doesn’t involve heat or direct contact, which makes it uniquely suited for delicate and high-precision work.

At Medalco, we use industrial-grade CNC-controlled waterjet machines to create custom stone pieces for cabinetry accents, fireplace surrounds, floor inlays, backsplashes, wall art, and even custom signage. Our facility in San Jose is equipped with advanced waterjet systems that give us full control over shape, thickness, and design complexity.

Why Accuracy Matters in Stone Design

1. Clean Cuts Mean Clean Installation

Stone is expensive and heavy and mistakes can be costly. With waterjet cutting, we can achieve ultra-precise edges, reducing the need for additional grinding or finishing. This results in a cleaner installation, shorter project timelines, and fewer headaches for everyone involved.

2. Detailed Patterns and Complex Designs

Whether it’s a floral medallion, a geometric motif, or custom Arabic or Latin typography etched into a slab, waterjet machines can replicate even the most intricate digital designs with perfect accuracy. This is a game-changer for luxury interiors and commercial projects seeking a unique visual identity.

3. Matching Seams and Joints

In large-format installations, alignment is critical. Our team at Medalco ensures seamless matching of edges and grains through waterjet’s repeatable precision, which is particularly valuable when working with veined marbles or patterned stones.

4. Minimal Waste

Accuracy reduces waste. When each cut is executed with millimeter-level precision, there’s less chance of ruining expensive stone materials. This also supports sustainability goals, which more and more clients are prioritizing.

Efficiency: Saving Time Without Cutting Corners

1. Faster Production Times

Compared to manual methods or even traditional saws, waterjet cutting significantly speeds up the fabrication process. Our CNC system allows us to batch multiple designs in one run, reducing production bottlenecks and expediting delivery.

2. Fewer Post-Processing Steps

Traditional stone cutting often requires polishing, sanding, and edge corrections. With waterjet, the cuts are so clean that many projects require little to no post-processing. This means fewer man-hours and lower costs overall.

3. Adaptable to Custom Projects

Each project is unique, and waterjet allows us to adapt designs quickly without having to change tooling. Need a revised curve or different thickness? We simply adjust the digital file. This flexibility makes it ideal for both one-off luxury projects and larger production runs.

Real-World Applications by Medalco

At Medalco, we’ve completed hundreds of custom stone design projects using waterjet technology. Here are a few highlights:

- Luxury Bathroom Vanity Tops: Featuring integrated sinks and decorative inlays without seams or awkward joints.

- Intricate Fireplace Surrounds: Cut from premium limestone, featuring carved accents that mirror antique European styles.

- Logo Inlays for Commercial Spaces: Precision-cut stone inlays embedded into lobby floors for brands that want to make a statement.

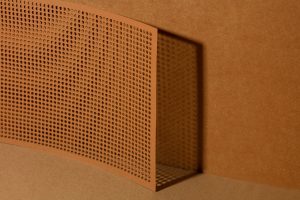

- Wall Art and Decorative Panels: Modern and abstract patterns designed by local artists and translated into stone with surgical accuracy.

Each of these projects was made possible by Medalco’s integrated design-to-fabrication workflow, where waterjet cutting plays a central role in turning creative visions into reality.

The Medalco Advantage

Why trust Medalco for your stone design needs?

- Custom Collaboration: We work with architects, interior designers, contractors, and homeowners alike to create one-of-a-kind results.

- In-House Capabilities: From 3D design to CNC programming to fabrication, we handle every step in our own facility. This means consistent quality and full accountability.

- Expert Team: Our designers and machine operators collaborate closely to ensure that technical feasibility meets artistic vision.

- State-of-the-Art Equipment: We invest in top-tier waterjet and CNC machines that can cut through stone, metal, glass, and composite materials.

Final Thoughts: Precision Is the New Luxury

In today’s world of high-end design, precision is no longer optional—it’s expected. And when it comes to stone, there’s simply no better method than waterjet cutting for delivering flawless accuracy, design flexibility, and time-saving efficiency.

At Medalco, we believe that true craftsmanship lies at the intersection of art and engineering. Our waterjet technology allows us to deliver both—whether we’re cutting stone for a kitchen backsplash or a museum-grade mosaic.

Let’s bring your next stone project to life with the precision it deserves.