How Long Does a Full Cabinet Installation Take?

Intruduction: Timelines Are More Than Dates on a Calendar

When people ask, “How long does a full cabinet installation take?” what they really want to know is: When will my space be usable and beautiful, without surprises? At Medalco, we’ve learned that time is the quiet ingredient behind every remarkable interior. Yes, the calendar matters. But so do workflow, sequencing, material behavior, and quality control.

A complete cabinet installation timeline typically ranges from 2 to 6 weeks for most residential projects once fabrication is complete, and 8 to 14 weeks when you include design, engineering, approvals, custom fabrication (including waterjet cutting for stone or metal inlays), finishing, logistics, and post-install curing. The wide range is not a hedge; it’s an honest reflection of scope, site conditions, and the materials you choose. In this guide, we’ll unpack the full journey from consultation to final hand-off, with real Medalco case notes and honest time windows for each phase.

You’ll see where waterjet technology tightens tolerances and saves days, where careful custom fabrication prevents do-overs, and where patient curing preserves finishes for the long run. Most of all, you’ll see how an installation timeline becomes predictable when it’s choreographed by a team that treats craft like engineering and schedule like a promise.

A High-Level Timeline (At a Glance)

If you’re scanning for a quick answer, here’s the typical cadence for a full, custom cabinet project:

- Discovery & Design (1–3 weeks): visioning, style, layout, preliminary budget, site measurements.

- Engineering & Shop Drawings (1–2 weeks): CAD/DWG, joinery details, hardware specs, integration points.

- Material Selection & Procurement (1–3 weeks): wood species, veneers, finishes; stone/metal/glass for inserts; hardware.

- Fabrication & Finishing (3–6 weeks): CNC milling, waterjet cutting for inlays and stone, assembly, sanding, finish systems, quality checks.

- Site Readiness & Pre-Install (1 week): substrate checks, electrical/plumbing coordination, protection of adjacent areas.

- Installation (3–10 days): base and wall cabinet set, paneling, scribing, crown/light valance, appliance panels, adjustments.

- Countertops, Stone & Specialty Panels (1–7 days depending on scope): templating or pre-cut fit, waterjet sink and fixture cutouts, final setting.

- Final Adjustments & Quality Control (1–2 days): reveals, alignment, soft-close tuning, finish touch-ups, sealers.

- Curing & Client Onboarding (2–7 days): finish cure, stone sealer set, care instructions, warranty kickoff.

Medalco reality check: Projects with multi-material design—for example, walnut doors with brass inlays and a book-matched stone backsplash—sit at the top end of these windows, not because they’re problematic, but because they deserve methodical planning and time to cure.

Phase 1: Discovery & Design (1–3 Weeks)

This is where you define style, function, and constraints. Medalco’s designers and project leads walk your space, laser-measure, and help align layout decisions with life. Do you need deep drawers for pots? A charging drawer? An appliance garage? Glass uppers? If you’re integrating stone, metal, or glass inserts, we’ll discuss how those materials behave and where waterjet cutting lifts the result from good to spectacular (for example, creating crisp, radius-free logos in metal or ultra-clean stone cutouts around outlets).

What accelerates this phase

- Having a mood board or inspiration folder (photos, saved projects, finish samples).

- Deciding early on appliance models and sink locations (they drive cabinet sizing).

- Openness to Medalco’s standard hardware lines (lead-times are shorter).

What can slow it down

- Scope changes mid-stream (e.g., switching to a different door profile that needs new tooling).

- Structural constraints discovered in older homes (a soffit hiding ductwork, a non-plumb wall that needs remediation).

Case note—Los Gatos Modern Farmhouse:

A client wanted walnut cabinetry with Calacatta marble inserts and a flush metal monogram on the range hood valance. By capturing the monogram in the design phase, we scheduled waterjet time up front and avoided mid-fabrication requests. Result: no delays, perfect symmetry.

Phase 2: Engineering & Shop Drawings (1–2 Weeks)

Once the design direction and budget are aligned, Medalco produces detailed shop drawings: cabinet elevations, sections, reveals, hardware call-outs, appliance panels, and tolerances for stone/metal/glass features. If a waterfall island or fluted panel requires waterjet-cut stone skirts or precision metal strapping, we set those tolerances here.

Why this matters for time:

Every hour of planning here saves days later. Clear drawings reduce installer “field thinking,” minimize change orders, and ensure upstream vendors (stone yards, metal fabricators, lighting suppliers) are synchronized.

Waterjet advantage:

We translate shop drawings directly into DXF or DWG for our waterjet. That means sink cutouts, backsplash outlets, radius-free corners, and inlay recesses are milled or cut with micrometer-level consistency. When the truck rolls up, parts fit.

Phase 3: Material Selection & Procurement (1–3 Weeks)

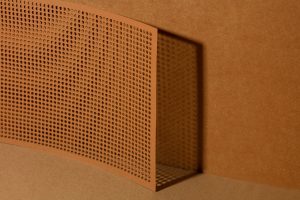

Time here depends on availability and finish choices. A stained white oak that’s common in stock may be quick; a custom-dyed walnut veneer or special-order brass mesh for glass doors takes longer. If you’re integrating stone, reserve slabs early and tag them with your job name; we’ll coordinate with the stone yard and schedule waterjet operations for any inserts or specialty panels.

Material behavior snapshot

- Wood: dimensionally “alive.” Great for warmth and acoustics; needs planning for seasonal movement.

- Veneered plywood: top-tier stability for doors and panels; excellent for consistent color/figure.

- Stone (marble, granite, quartzite): cold-cut with waterjet to avoid thermal micro-fractures; edge finishing matters.

- Metal (brass, stainless): expands more than stone; pairing them calls for invisible micro-gaps.

- Glass: waterjet can make clean apertures, but backing and feed rates must be controlled to prevent stress fractures.

Phase 4: Fabrication & Finishing (3–6 Weeks)

This is the longest single phase, and the heartbeat of quality. Medalco’s cabinet shop handles CNC joinery, case construction, and door/drawer builds while our finishing studio handles staining, painting, or catalyzed lacquer systems. In parallel, our waterjet team fabricates stone sill pieces, stone or metal inlays, and precision cutouts (sinks, faucets, pop-up power ports, and outlet reliefs for slab backsplashes).

Why waterjet matters here

- No heat-affected zone: critical for stone edge integrity and back-painted glass.

- Tight tolerances: inlay pockets and logos nest cleanly, reducing install adjustments.

- Complex geometries: floral patterns, micro-text lettering, and curved edge details are cut with repeatable precision.

Quality checkpoints that protect the schedule

- Dry-fit at the shop: We assemble banks of cabinets and specialty panels on a mock wall.

- Finish samples signed off: We run test panels (e.g., walnut with two stain options under your lighting temperature).

- Hardware test: Soft-close slides, hinges, pulls—tested and pre-drilled.

Case note, Cupertino Show Kitchen:

A chef-grade kitchen required an extra-thick quartzite island with a flush-set butcher block and a brushed brass accent line. We cut the brass strip on the waterjet and milled the island top to accept it. Because pocket and inlay were digital twins, on-site fit was instant, saving a full day of field work.

Phase 5: Site Readiness & Pre-Install (About 1 Week)

Before the first cabinet comes off the truck, our field team verifies subfloor levelness, wall plumb, and electrical/plumbing rough-ins. If floors are being refinished or tile is still curing, we sequence around it. Protection goes down: Ram Board, foam edges, plastic barriers, HEPA filters. We also stage stone slab handling paths to avoid tight turns that can chip edges.

Hidden time savers

- Confirm the appliance delivery date—panels, fillers, and reveals depend on real dimensions.

- Confirm lighting: puck lights, undercabinet strips, and drivers must be roughed and tested before panels go on.

- If using slab stone backsplashes, ensure the wall is laser-flattened; a day here avoids a week redoing seams.

Phase 6: Installation (3–10 Days, Typical)

This is the visible, satisfying part—where a blueprint becomes a room. Medalco’s installers proceed in a predictable sequence:

- Layout & Level (Day 1): Laser grid, locate high points in the floor, snap lines, set ledger boards if needed.

- Base Cabinets (Days 1–3): Start from the “true” corner, shim and fasten, maintain reveals, check plumb and level continuously.

- Wall Cabinets (Days 2–4): Hang with ledger support, align to laser, confirm appliance centerlines.

- Tall Cabinets & Panels (Days 3–5): Pantry, oven stacks, refrigerator housing, and gables go in.

- Trim, Crown, and Light Valance (Days 4–7): Scribe strips, fillers, and moldings are custom-fit; micro-adjustments matter for shadow lines.

- Hardware & Adjustments (Days 5–9): Pulls/handles, soft-close tuning, final door/drawer reveals.

- Jobsite Cleanup & Prep for Stone (Day 6–10): Clear, protect, and hand off for countertop set.

Note on small kitchens: A galley kitchen with standard cabinet runs can install in 3–4 days if walls are square and surfaces are true.

Note on complex projects: Multi-level islands, curved panels, appliance garages, and extensive paneling can extend to 7–10 days to get everything perfect.

Phase 7: Countertops & Specialty Panels (1–7 Days)

Depending on your workflow and preference, countertops may be templated after cabinet set or pre-cut if we’ve verified perfect site conditions. Medalco frequently uses waterjet to cut:

- Sink and faucet cutouts (undermount, farmhouse, integral).

- Outlet apertures for full-height stone backsplashes.

- Curved edges and intricate returns that would be risky with thermal cutting.

- Inset metal or stone medallions in waterfall ends or island centers.

Timing variables

- Templating and fabrication off-site: 3–5 business days for stone shops to cut, polish, and deliver (often faster for quartz, longer for exotic stones).

- On-site set & seam: Same day for straightforward runs; 1–2 days for multi-slab kitchens or large porcelain panels.

- Backsplash slabs: Add 1–2 days, especially when outlets or windows require precision cutouts.

Case note, San Jose Stone & Walnut Kitchen:

We pre-cut a Calacatta slab backsplash with waterjet outlet cutouts and a laser-true window return. Because the wall was prepared to within 1/16″, the entire slab set in hours, not days—and no grinder dust in the home.

Phase 8: Final Adjustments & Quality Control (1–2 Days)

Medalco’s 30-point QC checklist covers:

- Door/drawer alignment, soft-close action, and reveal uniformity.

- Crown/valance joints, scribe fill, and shadow line continuity.

- Panel/edge integrity, finish touch-ups, caulk lines where specified.

- Stone seams, lippage, and color match; stone sealer application and cure.

- Electrical test for integrated lighting and appliance panel alignment.

This is also when we do a client walkthrough. We love questions. We’ll show you how to adjust a hinge, care for the finish, and who to call if something feels off after move-in.

Phase 9: Curing, Commissioning & Onboarding (2–7 Days)

Fresh finishes, especially catalyzed lacquers or polyurethanes, benefit from stable temperature and low dust while they cure. Stone sealers typically need 24–72 hours to reach full protection (varies by chemistry). We provide a care kit and a simple maintenance schedule: how long before placing countertop appliances, when to wipe vs. deep clean, and what to avoid (e.g., citrus cleaners on marble).

What Really Drives the Timeline? (The “Why” Behind the Dates)

- Scope complexity: Pantries with roll-outs, appliance garages, glass uppers, and integrated lighting add steps.

- Material choices:

- Wood needs acclimation; veneered cores speed stability.

- Natural stone requires careful handling; porcelain slabs may need specialized setting.

- Metal inlays demand extra engineering for expansion.

- Site conditions: Out-of-square walls, uneven floors, or hidden utilities behind soffits add prep time.

- Trade coordination: Electricians, plumbers, and tile installers need to sequence precisely.

- Change orders: Switching a door profile or appliance model midstream is a timeline reset.

- Quality standards: Tight reveals and clean lines take time—and repay you every day you live with the result.

Where Waterjet Cutting Shaves Days (and Avoids Problems)

Because waterjet is cold-cut, it eliminates heat-related warping, micro-cracking, or burnt edges in stone, metal, and glass. Here’s how that translates to time:

- Fewer on-site adjustments: Pre-cut outlets and sink holes fit; no dusty rework in your home.

- Complex profiles in one pass: Curves, inner corners, and micro-text lettering happen at the machine—not with hours of hand-fettling.

- Repeatability: Matching multiple panels or mirrored island ends is straightforward.

- Material integrity: No thermal stress means fewer breaks and remakes.

Case note, Commercial Lobby Feature Wall (Sunnyvale):

Full-height porcelain panels with waterjet outlet and thermostat cutouts arrived ready to set. Installers placed 14 panels in a single day with perfect alignment because every cutout was exactly where the shop drawings said it would be. That’s a calendar win and a dust-free experience for the client’s tenants.

A Day-By-Day Example Timeline (Standard Kitchen)

Assumptions: 24 linear feet of cabinets, one island, quartz countertops, a few glass uppers, undercabinet lighting, and a stone slab backsplash.

- Week 1–2: Design, selections, appliance specs finalized.

- Week 3: Shop drawings; client approves.

- Week 4–8: Medalco fabrication, finishing, and waterjet operations for stone/glass/metal elements.

- Week 9 (Day 1–2): Site prep, protection, laser layout.

- Week 9 (Day 2–4): Base cabinets set; wall cabinets hung.

- Week 9 (Day 4–5): Tall cabinets, panels, crown/valance.

- Week 9 (Day 5–6): Hardware, adjustments, lighting prep.

- Week 10 (Day 1–2): Countertop templating and/or set.

- Week 10 (Day 3–4): Slab backsplash set; sealer applied.

- Week 10 (Day 5): Final QC, client walkthrough.

- Week 10 (Weekend): Curing; move-in friendly early next week.

How to Shorten the Timeline, Without Cutting Corners

- Decide appliances early. Panels and reveals depend on real specs.

- Choose stock or quick-ship hardware finishes. Lead-times matter.

- Lock scope before we cut. Change orders create ripple delays.

- Accept Medalco’s recommended sequences. For example: cabinets first, then floors can be risky; often flooring precedes base cabinets for the cleanest elevation.

- Bundle specialty work with us. When Medalco handles waterjet, cabinetry, and stone, fewer hand-offs mean fewer slowdowns.

Real-World Medalco Snapshots: Timelines with Texture

Walnut + Brass Chef’s Kitchen (Cupertino)

- Scope: Frameless walnut cabinetry, integrated hood, brushed brass inlay on the island, quartzite counters, slab backsplash with waterjet outlet cutouts.

- Timeline: 11 weeks total (design to walkthrough).

- Why it worked: Early monogram/inlay decisions, tight shop drawings, waterjet pre-cuts for outlets and faucet. No field grinding in client’s home.

- Client win: Cooked a family meal 48 hours after QC, no dust, no mess, no drama.

Minimalist Porcelain Wall System (Sunnyvale Office)

- Scope: Full-height ultra-thin porcelain panels, hidden hardware, thermostat and outlet apertures via waterjet.

- Timeline: 7 weeks (fast-tracked).

- Keys: Staggered fabrication and site prep in parallel, precise digital layout, adhesive system tuned for porcelain’s rigidity.

- Lesson: When the design is precise, schedule becomes precise.

San Jose Modern Farmhouse

- Scope: Painted shaker with Calacatta marble inserts on select doors, appliance garage, open-shelf niche with hidden lighting, walnut drawer interiors.

- Timeline: 12 weeks (custom finishes + stone inlays).

- Waterjet role: Cut marble inserts and created flush recesses; reduced on-site fitting to minutes per door.

- Outcome: A timeless, high-touch kitchen where every reveal is intentional.

Frequently Asked Questions (FAQs)

| 1. How long do just the cabinets (no counters) take to install? A straightforward run installs in 3–5 days. Add time for tall units, paneling, and intricate trim. |

| 2. Can you install cabinets and countertops in the same week? Often yes. If countertops are pre-cut or templated early, we can set them within 1–3 days of cabinet completion. |

| 3. What if my walls aren’t square or floors aren’t level? We plan for it. Laser leveling, shims, and scribe fillers make your cabinets look perfectly square even when the room isn’t. Expect an extra ½–1 day for challenging rooms. |

| 4. Will waterjet speed up my project? It speeds the right parts: precision cutouts, inlays, and complex profiles. It also prevents the slowdowns caused by on-site rework and dust. |

| 5. Is there a “rush” option? We can compress phases by overlapping tasks and prioritizing shop time, but we never compromise curing or QC. Fast is good; flawless is better. |

Trusted External Resources

- Flow Waterjet — Benefits of Waterjet Cutting

- OMAX Waterjet — Educational Resources

- NKBA — Planning Guidelines for Kitchens

- Fine Homebuilding — Cabinetry Techniques & Best Practices

- The Spruce — Cabinet Installation Basics