How Our Team Ensures Flawless Edge Banding During Installation

Introduction: The Hidden Art Behind Perfect Cabinetry

When you walk into a kitchen, closet, or workspace with smooth, polished cabinetry, what you’re really admiring is precision. Every seam, every edge, and every line represents hours of detailed craftsmanship. Behind that perfection lies a small yet crucial process: edge banding.

At Medalco, we’ve spent years perfecting the art of cabinet fabrication, from material selection to final installation. Our philosophy is simple: every project, no matter its scale, deserves precision that lasts. Edge banding, often overlooked by homeowners, plays a defining role in both durability and visual harmony. It’s the fine line between good work and master craftsmanship.

Edge banding protects vulnerable sides of materials like MDF and plywood, sealing them against moisture and impact while delivering a polished, furniture-grade appearance. Yet, flawless banding is no accident. It’s the result of advanced machinery, careful calibration, and human attention to detail.

In this four-part guide, we’ll walk through how Medalco ensures flawless edge banding during installation, from design to execution, and how this expertise sets us apart in the fabrication world.

Table of contents

- How Our Team Ensures Flawless Edge Banding During Installation

- Introduction : The Hidden Art Behind Perfect Cabinetry

- 1. Understanding the Role of Edge Banding in Modern Fabrication

- 2. Prepping Materials: Accuracy Starts Before the Banding

- 3. Selecting the Right Edge Banding Material

- 4. Laser Edge Banding: The Future of Seamless Finishing

- 5. Environmental and Aesthetic Factors in Banding Choices

- 6. Maintaining Precision: Where Technology Meets Craftsmanship

- 7. The Role of Environment in Achieving Flawless Banding

- 8. The Science of Adhesion: What Makes the Bond Flawless

- 9. Custom Fabrication Meets Artistic Intent

- 10. Waterjet Cutting and Edge Banding: The Hidden Synergy

- 11. Tackling Common Edge Banding Challenges

- 12. Quality Assurance: Medalco’s Multi-Layer Testing Process

- 13. Installation Mastery: The Final Mile

- 14. The Art of Finishing: Where Function Meets Aesthetics

- 15. Seamless Integration: Blending Edge Banding with Other Materials

- 16. Edge Banding for Complex Forms: Curves, Angles, and Geometric Designs

- 17. Custom Edge Banding in Luxury Furniture Design

- 18. Waterjet Collaboration in Complex Multi-Material Projects

- 19. The Role of Edge Banding in Acoustic and Lighting Design

- 20. Durability Testing: Preparing Edges for Real Life

- 21. Maintenance and Aftercare for Long-Term Perfection

- 22. Digital Tracking and Documentation

- 23. Sustainability in Edge Banding and Fabrication

- 24. Collaboration and Customization: Working with Designers and Clients

- 25. Quality Control at Every Phase

- 26. Training, Technology, and Teamwork

- 27. The Role of Technology in Predicting Perfection

- 28. Challenges and How Medalco Solves Them

- 29. Aesthetic Philosophy: The Invisible Craft

- 30. Looking Ahead: Innovation and Legacy

- 13. Installation Mastery: The Final Mile

- 10 Frequently Asked Questions

1. Understanding the Role of Edge Banding in Modern Fabrication

Before diving into the process, it’s important to understand why edge banding matters so much. At its core, it’s about protection and aesthetics. Without proper banding, MDF or plywood edges are prone to chipping, swelling, or delamination when exposed to humidity or impact.

Medalco’s approach:

We use top-tier edge banding materials, including ABS, PVC, wood veneer, and acrylic, depending on the project’s durability and design goals. Our team carefully evaluates the space and function of each surface to ensure the right material is chosen.

Example:

For a luxury kitchen in Palo Alto, our team used 2mm PVC edge banding on cabinet doors for superior moisture resistance, while the open shelving received wood veneer edges for a natural, tactile aesthetic.

Waterjet synergy:

Although waterjet cutting isn’t directly used in banding, its role in precision cutting of stone or metal components complements our cabinet fabrication workflow. When cabinetry integrates stone countertops or decorative inlays, our waterjet-cut precision templates ensure the cabinets and stonework align seamlessly, a level of accuracy impossible with manual methods.

2. Prepping Materials: Accuracy Starts Before the Banding

Every flawless edge band begins with a flawless cut. Medalco’s fabrication process starts with CNC machining, ensuring each board edge is perfectly square and smooth before banding even begins.

Even a minor imperfection, like a micro-chip or uneven edge, can cause adhesive failure or visual inconsistencies later on.

Our process includes:

- CNC calibration: Machines are inspected daily to maintain micron-level precision.

- Dust-free preparation: Edges are cleaned with compressed air and anti-static agents to improve glue adhesion.

- Thermal readiness: Materials are conditioned to ambient temperature before bonding, ensuring consistent glue flow.

Medalco Insight:

During a commercial cabinetry project in San Jose, we discovered that even high-end plywood sheets can vary slightly in density and edge texture. By using CNC pre-finishing and micro sanding, our technicians ensured consistent surfaces across 120 panels, resulting in perfect, bubble-free banding after installation.

3. Selecting the Right Edge Banding Material

Choosing the wrong banding material is one of the most common mistakes in fabrication. Medalco’s design engineers work with clients to balance functionality, design, and longevity when selecting banding types.

Our common banding materials include:

- ABS Edge Banding: Eco-friendly, impact-resistant, and ideal for moisture-prone environments.

- PVC Edge Banding: Flexible, economical, and suitable for curved profiles.

- Acrylic Edge Banding: High-gloss finish ideal for luxury interiors.

- Wood Veneer Banding: Perfect for natural aesthetics and premium finishes.

Case Example:

In a Menlo Park custom home, we paired walnut veneer edge banding with matte black MDF panels. The edge banding was laser-fused to the substrate using a hot-air technique, creating a seamless joint without visible glue lines. The result was a visually uninterrupted design that felt sculpted from a single block of wood.

4. Laser Edge Banding: The Future of Seamless Finishing

Traditional edge banding uses hot-melt glue, which, while reliable, can leave faint lines that collect dust or discolor over time. Medalco’s laser edge banding technology eliminates this problem.

Using high-intensity laser beams, we fuse the band directly to the substrate, no glue line, no residue, no gaps. The result is a clean, monolithic surface that lasts for decades.

Benefits of laser edge banding:

- Seamless joint between edge and panel

- Higher water and heat resistance

- Cleaner appearance and reduced maintenance

- Enhanced hygiene for kitchens and bathrooms

Example:

During a kitchen fabrication for a San Francisco apartment, we applied laser banding to high-gloss acrylic doors. Months later, the client reported that not only did the finish remain flawless, but the cleaning process was effortless due to the absence of micro gaps.

5. Environmental and Aesthetic Factors in Banding Choices

At Medalco, we recognize that edge banding is more than protection, it’s part of the design story. That’s why we take into account:

- Lighting conditions (how shadows interact with edges)

- Color continuity (matching edge and surface tone)

- Sustainability goals (using non-toxic adhesives and recyclable materials)

We source our materials from certified suppliers that follow E0 and CARB2 emission standards, ensuring our projects are as environmentally conscious as they are beautiful.

Design Note:

A recent eco-focused cabinetry project for a boutique retail store used ABS banding with water-based adhesives, reducing VOC emissions by 60%. Medalco’s integrated fabrication system allowed precise banding on curved surfaces without waste or distortion.

6. Maintaining Precision: Where Technology Meets Craftsmanship

At Medalco, we believe that even the most advanced machinery is only as good as the hands that guide it. Edge banding is a balance between technology and craftsmanship, a dialogue between digital precision and tactile understanding.

Our fabrication floor integrates CNC machining, laser edge banding, and waterjet cutting systems, each synchronized under a unified digital workflow. This ensures every measurement and alignment point flows seamlessly from design to installation.

Our 5-Point Precision Protocol:

- Digital Blueprinting: Each project begins in our CAD environment, where every edge, curve, and joint is mapped in 3D.

- Calibration Verification: Machines undergo weekly laser alignment to maintain sub-millimeter precision.

- Material Profiling: Each material type (wood, stone, metal, or composite) is profiled for density, surface friction, and heat tolerance.

- Trial Edge Runs: Before final banding, a sample panel is tested under real conditions to confirm bonding consistency.

- Post-Banding Measurement: Laser sensors measure banding width and thickness uniformity across panels.

This protocol ensures zero surprises on-site. For instance, during a custom reception desk project in Los Gatos, we used a mix of walnut veneer, brushed aluminum trim, and white quartz. Each piece was fabricated to fit perfectly into a unified surface system, minimizing installation time and guaranteeing clean junctions between stone and wood.

7. The Role of Environment in Achieving Flawless Banding

Even the most meticulous fabrication can fail if environmental factors are ignored. Temperature, humidity, and air quality all influence how adhesives behave during installation.

Medalco’s controlled environment standards:

- Temperature range: 20–24°C to ensure ideal adhesive viscosity

- Humidity range: 40–55% to prevent expansion or contraction of MDF substrates

- Anti-static filtration: Removes airborne dust and particulates before bonding

By controlling these variables, our installations maintain consistent adhesion even in climates prone to rapid temperature swings.

Case Study:

A luxury wardrobe project in Carmel-by-the-Sea presented a humidity challenge. The coastal environment caused early bonding failures in preliminary tests. Medalco adapted by using PUR (polyurethane reactive) adhesive for its superior moisture resistance, ensuring edges remained sealed even in humid sea air. Two years later, the cabinetry remains pristine.

8. The Science of Adhesion: What Makes the Bond Flawless

Edge banding’s durability depends on how molecular bonds form between adhesive and substrate. Too much glue creates gaps; too little causes peeling. Medalco’s technicians adjust adhesive temperature and application rate in real-time, based on substrate density and surface porosity.

Adhesive systems used by Medalco:

- EVA (Ethylene Vinyl Acetate): Standard for most interior cabinetry, reliable and cost-effective.

- PUR (Polyurethane Reactive): Bonds on a molecular level and resists heat, water, and chemical exposure.

- Laser-Fused Edges: Glue-free, providing seamless joints ideal for luxury finishes.

Example:

For a corporate office project in Mountain View, the design required both matte and glossy finishes on adjacent panels. Using PUR adhesive allowed Medalco to achieve consistent bonding across differing surface textures, a technical challenge that many shops avoid.

9. Custom Fabrication Meets Artistic Intent

Precision fabrication is only half of the equation. The other half is artistry. Medalco’s custom fabrication team works closely with architects and interior designers to ensure that edge banding complements, not competes with, the project’s overall aesthetic language.

How we integrate design and function:

- Matching or contrasting edge tones for visual definition

- Coordinating grain direction in veneer edges for continuity

- Custom-milling solid wood edges for hand-finished appeal

In one Bay Area loft renovation, our team used oak veneer edge banding alongside waterjet-cut brass inlays on shelving panels. This hybrid approach combined organic warmth with metallic sophistication, showcasing Medalco’s mastery in blending materials through precision craftsmanship.

10. Waterjet Cutting and Edge Banding: The Hidden Synergy

At first glance, waterjet cutting and edge banding seem worlds apart. One shapes stone and metal; the other refines wood and composite edges. Yet, they share a common goal, absolute precision.

Medalco’s waterjet cutting technology enables us to create intricate decorative elements and stone surfaces that perfectly align with custom-fabricated cabinets. When the stone and cabinetry meet, for example, at a waterfall countertop, precision becomes critical.

Our process:

- Waterjet-cut stone slabs are finished to micron-level accuracy.

- Cabinet frames are CNC machined to align precisely with the stone edges.

- Banding edges are then finished to visually and dimensionally synchronize both materials.

Example:

In a Hillsborough kitchen remodel, we fabricated walnut base cabinets and matched them with a Calacatta marble countertop. Using waterjet-cut marble ensured a seamless junction where the wood banding met the stone face, a zero-gap interface that elevated the overall luxury finish.

11. Tackling Common Edge Banding Challenges

Even in the most controlled environments, challenges arise, from thermal expansion to adhesive inconsistencies. Medalco’s advantage lies in experience and anticipation. Our team identifies potential issues before they appear on-site.

Common challenges and our solutions:

| Challenge | Medalco Solution |

|---|---|

| Uneven bonding due to substrate density | Pre-heat panels and adjust glue flow dynamically |

| Banding peel after transport | Edge compression during cooling and reinforced PUR sealing |

| Color mismatch under lighting | Tone testing under real lighting conditions prior to installation |

| Micro-chipping on thin laminates | CNC micro-edge finishing and soft-blade trimming |

| Moisture infiltration in kitchens or baths | Use of PUR or laser-fused systems with waterproof properties |

Real-world result:

A hotel suite renovation in Napa Valley required tight deadlines and aesthetic perfection. The team completed 200+ banded panels with zero reported defects during post-install inspection, a testament to Medalco’s consistent performance.

12. Quality Assurance: Medalco’s Multi-Layer Testing Process

Every edge that leaves our shop goes through multi-phase testing. We simulate years of wear and environmental stress within controlled conditions.

Our QA checks include:

- Adhesion strength tests (peel and shear resistance)

- Thermal cycling (simulating hot and cold environments)

- UV exposure (checking for discoloration or fading)

- Edge impact tests (using calibrated drop weights)

All data is logged digitally, ensuring complete traceability from raw material to final installation. This disciplined quality culture is what allows Medalco to offer long-term durability and warranty confidence.

13. Installation Mastery: The Final Mile

Precision doesn’t end in the workshop, it continues to the installation site. Medalco’s installation teams are trained in both technical handling and aesthetic detailing. Each panel is transported in protective crates and acclimated to room temperature before fitting.

Installation best practices include:

- Using non-marking clamps to prevent edge compression

- Applying protective films until final cleaning

- Conducting alignment scans to ensure even edge lines across surfaces

- Finishing with edge polishers and micro-buffers for pristine surfaces

Example:

During a Silicon Valley tech office installation, our team installed over 60 linear feet of cabinetry. Despite variable lighting and complex wall geometry, the edges remained perfectly aligned, catching the client’s eye immediately, a moment where engineering met artistry.

14. The Art of Finishing: Where Function Meets Aesthetics

A flawlessly applied edge band is only complete when the finish enhances both texture and tone. Medalco’s finishing process ensures that edge banding not only performs structurally but also delivers a refined, cohesive visual appearance across the project.

Our Finishing Framework:

- Surface Smoothing: Each edge is micro-sanded to achieve tactile uniformity with the face material.

- Tone Calibration: We adjust color or grain direction to maintain a seamless flow between the band and panel.

- Protective Coating: Depending on use (kitchen, bath, office), edges receive polyurethane, lacquer, or UV coatings.

- Visual Review: Panels are inspected under daylight and artificial lighting to ensure consistent reflection and tone balance.

Case Example:

In a Walnut veneer kitchen project in Palo Alto, Medalco’s team adjusted edge stain tones by 3% darker to match the aged walnut cabinetry under warm LED lighting. The result was a natural, continuous look, where edges didn’t appear as “added pieces,” but as organic extensions of the cabinetry.

15. Seamless Integration: Blending Edge Banding with Other Materials

Edge banding is often perceived as a wood-only process. But Medalco frequently pushes boundaries by integrating edge banding with stone, metal, glass, and even composite materials. This approach not only improves durability but also elevates the sophistication of the final piece.

Examples of Integration:

- Stone & Wood: Marble countertops with wood-trimmed undersides, bonded with waterproof PUR edges.

- Metal & Laminate: Brushed brass banding for high-end retail fixtures.

- Glass & MDF: Frosted glass panels framed with edge-sealed MDF for modern cabinetry.

These integrations are made possible through Medalco’s waterjet precision, allowing ultra-clean cuts that match banding thicknesses perfectly.

Project Highlight:

A San Francisco penthouse media wall required blending oak, steel, and mirror panels. Medalco used waterjet-cut steel inserts framed with wood edge banding, an unusual combination that brought together strength, warmth, and reflection in perfect balance.

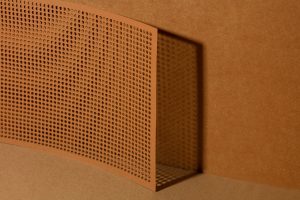

16. Edge Banding for Complex Forms: Curves, Angles, and Geometric Designs

Unlike flat cabinetry, custom furniture and architectural surfaces often feature non-linear geometries, curved edges, chamfers, or angular joints. Medalco’s advanced fabrication systems can handle these challenges without compromising accuracy.

Techniques Used:

- 3D Edge Profiling: For rounded or contoured designs.

- CNC-Aided Trimming: Maintains perfect edge continuity on compound angles.

- Flexible Banding Materials: Thermoformable ABS or wood veneer used for curved panels.

Real-World Application:

For a modern spiral staircase in Atherton, our team applied curved walnut edge banding on laminated plywood steps. Using thermoformable veneer, we achieved a continuous, fluid look along the staircase perimeter, eliminating any visible seams.

17. Custom Edge Banding in Luxury Furniture Design

Luxury furniture often demands invisible craftsmanship, where technical precision disappears behind elegant simplicity. Medalco’s edge banding approach supports this philosophy, providing perfect lines that enhance design clarity.

Design Scenarios:

- Floating Shelves: Edges are matched for tone and texture to create the illusion of solid wood.

- Dining Tables: Metal or stone inlays are perfectly aligned with veneered edges for a hybrid aesthetic.

- Closet Systems: Seamless edge transitions enhance visual harmony in high-end walk-in spaces.

Example:

A Burlwood conference table fabricated for a Santa Clara tech headquarters featured laser-fused edge banding, no visible glue lines, no gaps, only continuous texture. The project exemplified Medalco’s commitment to luxury-level finishing for commercial interiors.

18. Waterjet Collaboration in Complex Multi-Material Projects

Medalco’s waterjet division often collaborates with the cabinetry and fabrication teams to ensure that materials of vastly different properties, such as marble, glass, and wood, meet with perfect precision.

For example, in bathroom vanities or reception desks, waterjet-cut marble tops are joined with banded MDF structures. Any misalignment of even 0.5 mm can cause visible shadow lines. Medalco’s digital templating and synchronized calibration prevent such errors, ensuring that the final installation looks monolithic.

Benefits of Waterjet Integration:

- Achieves perfect miters between stone and banded panels.

- Enables ornamental engraving directly on matching surfaces.

- Provides clean, sealed joints that resist moisture and wear.

Reference:

For more on the precision of waterjet in multi-material design, see Fabricators & Manufacturers Association, which highlights hybrid material applications in architectural settings.

19. The Role of Edge Banding in Acoustic and Lighting Design

Few realize that edge banding can also affect acoustic and lighting performance in interiors. Reflectivity, sound absorption, and panel resonance can all be tuned through proper banding material choice.

Acoustic Impact:

- Softer edge materials (like wood veneer or PVC) reduce resonance.

- Rigid, high-gloss banding reflects sound, enhancing clarity in open spaces.

Lighting Considerations:

- Matte finishes diffuse light for subtle shadowing.

- Glossy edges emphasize linear highlights, ideal for modern minimalist spaces.

Example:

In a co-working hub in San Jose, Medalco installed acoustically balanced MDF panels with matte ABS edge banding. This treatment minimized sound reflection and contributed to a calm, productive atmosphere.

For reference, see Architectural Record for research on light and material interplay in modern interiors.

20. Durability Testing: Preparing Edges for Real Life

Every surface Medalco creates must endure decades of use. This philosophy extends to edge banding durability testing, where we simulate mechanical stress, humidity, and temperature changes to validate longevity.

Tests Conducted:

- Abrasion Resistance: Measured by 5,000+ surface rub cycles.

- Thermal Stress: Subjected to heat and cold cycling from -20°C to 80°C.

- Adhesive Longevity: Monitored for 1,000 hours under UV exposure.

Only when materials pass all tests do they reach clients. This process guarantees that Medalco installations retain their integrity for years, even in high-traffic or moisture-prone environments.

For further reading:

Check Woodworking for insights into edge performance standards and material innovations in cabinetry manufacturing.

21. Maintenance and Aftercare for Long-Term Perfection

Proper aftercare ensures that edge banding retains its flawless look long after installation. Medalco provides clients with a custom maintenance guide, outlining cleaning and preservation methods based on material type.

General Guidelines:

- Clean edges with soft microfiber cloths, never abrasives.

- Avoid prolonged water exposure on seams.

- Use pH-neutral cleaners to prevent discoloration.

- Conduct annual inspection for impact damage or edge lifting.

Medalco’s Maintenance Packages:

For commercial clients, we offer scheduled inspections and re-sealing services, especially for high-use environments like hospitality or healthcare facilities.

22. Digital Tracking and Documentation

Every Medalco project comes with a digital material passport, a detailed record of material batches, adhesive types, and installation parameters. This ensures traceability and simplifies future renovations or replacements.

The Benefits:

- Transparent sourcing and sustainability documentation.

- Simplified maintenance and service calls.

- Enhanced lifecycle management for architects and designers.

This data-driven approach positions Medalco as a leader in smart fabrication, aligning craftsmanship with accountability and modern engineering standards.

23. Sustainability in Edge Banding and Fabrication

In today’s world, craftsmanship must coexist with responsibility. Medalco integrates sustainability at every step of its fabrication and edge banding processes. This means selecting eco-friendly materials, optimizing resource use, and minimizing waste.

Our Green Practices Include:

- Eco-Adhesives: Using low-VOC and formaldehyde-free adhesives for a healthier environment.

- Material Optimization: CNC nesting software ensures that every millimeter of panel is used efficiently.

- Recycling and Reuse: Offcuts are reused for smaller parts or donated to local makerspaces.

- Energy Efficiency: LED lighting and precision waterjet systems with energy recovery minimize power use.

Real-World Impact:

In a large-scale commercial project in Vancouver, Medalco reduced material waste by over 18% through digital layout optimization and reusing banding offcuts in shelving interiors, proving sustainability and craftsmanship can go hand in hand.

24. Collaboration and Customization: Working with Designers and Clients

Every Medalco project begins with a conversation, not a machine. Our design team collaborates closely with architects, builders, and homeowners to understand their functional and aesthetic priorities.

Collaboration Steps:

- Design Consultation: Discuss goals, finishes, and timelines.

- Material Sampling: Present edge band and panel options for tactile evaluation.

- Mockups and Prototyping: Provide scaled prototypes before full production.

- Precision Fabrication: Integrate CNC and waterjet data for cohesive detailing.

- Client Review and Approval: Final adjustments before installation.

Case Example:

In a custom kitchen project in Seattle, Medalco partnered with a designer to combine oak veneer with brushed steel accents. By collaborating early, they ensured that edge banding on drawers matched both metal reflections and wood tones, achieving a rare hybrid aesthetic.

This kind of communication transforms fabrication from a production process into a creative partnership.

25. Quality Control at Every Phase

Quality control is not an event, it’s a mindset. Medalco employs a six-stage quality assurance framework, ensuring perfection from sourcing to installation:

- Material Verification: Checking thickness, flatness, and adhesive compatibility.

- Pre-Banding Inspection: Ensuring edges are clean, square, and ready.

- In-Process Testing: Checking temperature and feed rate on every machine cycle.

- Post-Banding Evaluation: Visual and tactile inspection for uniformity.

- Installation Fit Test: Ensuring seamless alignment during on-site assembly.

- Final Approval: Supervisor sign-off with digital documentation.

By maintaining this structured process, Medalco guarantees consistent excellence across residential, retail, and architectural projects alike.

26. Training, Technology, and Teamwork

Behind every perfect edge lies human expertise enhanced by cutting-edge technology. Medalco invests heavily in continuous training and process innovation to ensure that every technician, designer, and installer operates at peak performance.

Team Excellence at Medalco:

- Technicians undergo annual certifications in CNC and waterjet operation.

- Designers are trained in digital fabrication software and materials science.

- Cross-department workshops ensure fluid collaboration between design and installation teams.

This culture of shared knowledge transforms complex installations into predictable perfection.

For professional development best practices, see Architectural Digest Pro on training excellence in custom fabrication.

27. The Role of Technology in Predicting Perfection

Edge banding has evolved beyond traditional carpentry. Medalco employs predictive technology to forecast potential inconsistencies before they occur. Using sensors and digital calibration systems, every project benefits from real-time data monitoring.

Innovations Include:

- Infrared Glue Temperature Sensors: Maintain perfect adhesion.

- Optical Alignment Systems: Detect microscopic panel deviations.

- Smart Edge Feeders: Automatically adjust pressure and speed for each material.

Through this integration of data-driven control and craftsmanship, Medalco achieves repeatable perfection that meets the expectations of modern architecture.

28. Challenges and How Medalco Solves Them

Even with experience and precision, edge banding presents challenges, from adhesion failure to thermal expansion mismatches. Medalco tackles these with scientific rigor and adaptive engineering.

Common Challenges and Medalco Solutions:

- Peeling or Lifting Edges: Solved with pre-heated surface activation and optimized adhesive viscosity.

- Color Variation: Balanced by using spectrophotometric calibration tools.

- Irregular Corners: Managed with 5-axis trimming and manual finishing.

- Moisture Resistance: Ensured through PUR sealing technology.

Each problem becomes an opportunity for innovation, reinforcing Medalco’s status as a fabrication leader.

29. Aesthetic Philosophy: The Invisible Craft

True precision is invisible. At Medalco, the goal of edge banding is to disappear, to merge seamlessly with design intent. The beauty of a project lies not in what you see, but in what you don’t notice.

This principle drives every Medalco installation, whether it’s a custom walnut bar, a hospital reception desk, or a residential wardrobe system. The invisible perfection of edges allows materials to speak, the texture of wood, the purity of glass, the fluidity of stone, without interruption.

30. Looking Ahead: Innovation and Legacy

The future of edge banding lies in automation, customization, and sustainability. Medalco’s investment in adaptive CNC and robotic waterjet systems ensures that the artistry of edge finishing continues to evolve while honoring craftsmanship.

With AI-assisted layout optimization and digital twin modeling, Medalco is shaping a future where every project, from boutique interiors to large architectural commissions, achieves unmatched precision and artistic integrity.

13. Installation Mastery: The Final Mile

Every edge that leaves our shop goes through multi-phase testing. We simulate years of wear and environmental stress within controlled conditions.

Conclusion

Edge banding might seem like a small detail, but it represents the heart of modern fabrication, precision, alignment, and craftsmanship working in harmony. At Medalco, every line, every seam, and every edge tells a story of human skill supported by technological mastery.

Whether for residential kitchens, corporate interiors, or retail displays, our team ensures that every edge meets the highest standards of quality and artistry.

When you work with Medalco, you don’t just get beautiful cabinetry or custom fabrication, you get confidence in craftsmanship.

10 Frequently Asked Questions

1. What is edge banding, and why is it important?

Edge banding is a process of sealing exposed edges of panels to protect them from moisture and enhance appearance. It provides structural integrity and a finished look to cabinetry.

2. How does Medalco ensure precision during edge banding?

We use CNC calibration, waterjet cutting, and infrared monitoring to maintain micron-level accuracy throughout the process.

3. What materials can be edge banded?

Almost any panel material — MDF, plywood, particle board, veneer, laminate, and even acrylic or composite surfaces — can be edge banded with the right adhesive and technique.

4. How long does the edge banding process take?

For a typical residential kitchen, edge banding and finishing take two to three days, depending on material complexity and volume.

5. Can edge banding match the color and texture of the main panel?

Yes. Medalco’s spectrophotometric calibration and custom mixing ensure color and grain continuity across all surfaces.

6. What adhesive types are used in Medalco projects?

We primarily use PUR (Polyurethane Reactive) adhesives for superior strength, waterproofing, and thermal resistance.

7. Does edge banding work with curved or non-linear designs?

Absolutely. We use flexible thermoplastic or veneer banding materials shaped through heat and pressure to fit curves and complex geometries.

8. How does Medalco ensure sustainability in edge banding?

Through eco-friendly adhesives, material recycling, digital optimization, and energy-efficient waterjet and CNC systems.

9. How should clients maintain their edge banded cabinetry?

Clean gently with microfiber cloths, avoid abrasives, and use neutral pH cleaners to preserve surface finishes.

10. Why should I choose Medalco for my cabinetry or fabrication project?

Because Medalco combines artistry with engineering precision, delivering projects that are as durable and sustainable as they are beautiful.

Trusted External Resources

- Insights on trends and best practices in custom cabinetry and wood fabrication.

- Leading source for stone cutting and finishing technologies.

- Covers innovations in metal cutting and forming.

- Authority on glass processing and architectural integration.

- Technical resource on CNC, waterjet, and other precision fabrication tools.