MDF vs. Plywood: Which Is Better for Your Cabinets

At Medalco, where we specialize in cabinet fabrication, stone design, and precision waterjet cutting, this question comes up every single week from homeowners, designers, and contractors. In this deep-dive, we’ll share real insights, case studies from our projects, and design lessons we’ve learned along the way to help you decide which material is right for you.

Table of contents

- MDF vs. Plywood: Which Is Better for Your Cabinets

- Introduction: Why Cabinet Material Matters

- What Is MDF?

- What Is Plywood?

- Head-to-Head Comparison: MDF vs. Plywood

- How Medalco Uses Waterjet Cutting in Cabinet Design

- Aesthetic Value: Finishes, Textures, and Customization

- Durability in Real-World Use

- Moisture and Heat Resistance

- Cost Analysis: Which One Truly Saves Money?

- Environmental & Eco-Friendly Considerations

- Case Study: A Medalco Kitchen Transformation

- Case Study: Commercial Cabinets & Plywood Longevity

- Artistic and Architectural Value

- Common Myths About MDF vs. Plywood

- When to Choose MDF

- When to Choose Plywood

- Hybrid Cabinet Solutions

- What Designers & Builders Should Know

- Maintenance & Longevity Tips

- Conclusion: Which Is Better?

- Frequently Asked Questions (FAQs)

Introduction: Why Cabinet Material Matters

Cabinets are more than storage. They’re design anchors that carry daily wear and tear, spills, and seasonal temperature swings. Whether you’re installing sleek modern cabinetry in San Jose or a rustic design for a Napa Valley winery, the choice of material directly affects longevity, beauty, and value.

At Medalco, we’ve seen homeowners fall in love with a design, only to regret their choice of cabinet material a few years later. That’s why understanding MDF vs. Plywood is essential before you invest.

What Is MDF?

Medium-Density Fiberboard (MDF) is engineered wood made from wood fibers, wax, and resin, compressed under heat and pressure. The result? A dense, smooth material that’s excellent for painted finishes.

Pros of MDF:

- Smooth surface perfect for painting.

- Consistent texture with no knots or grain irregularities.

- Easy to cut intricate shapes, ideal for Medalco’s waterjet-cut cabinet doors.

- Affordable compared to plywood

Cons of MDF:

- Heavy and less rigid than plywood.

- Susceptible to water damage if unsealed.

- Doesn’t hold screws as strongly as plywood.

Think of MDF like modeling clay, it’s versatile and forgiving, but not indestructible.

What Is Plywood?

Plywood is created by stacking thin layers of wood veneer, glued together with alternating grain directions. This gives it strength and flexibility.

Pros of Plywood:

- Superior screw-holding capacity.

- Lightweight compared to MDF.

- Handles moisture better.

- Visible wood grain, great for natural finishes.

Cons of Plywood:

- More expensive than MDF.

- Can warp if not properly sealed.

- Surface may show voids or imperfections.

Plywood is like the athlete of cabinet materials, lean, strong, and resilient.

Head-to-Head Comparison: MDF vs. Plywood

| Feature | MDF | Plywood |

| Strength | Dense but brittle | Strong and flexible |

| Moisture Resistance | Poor if unsealed | Moderate with sealing |

| Finish Options | Best for painting | Best for staining & wood look |

| Weight | Heavier | Lighter |

| Cost | Lower | Higher |

| Screw Holding | Weak | Strong |

| Cutting Detail | Excellent (CNC/Waterjet) | Good, less precise than MDF |

At Medalco, we often recommend MDF for painted modern cabinets and plywood for structural strength in kitchens or bathrooms.

How Medalco Uses Waterjet Cutting in Cabinet Design

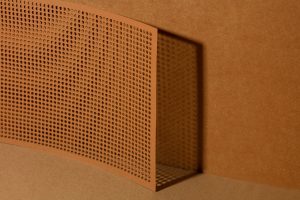

This is where we separate theory from artistry. With our state-of-the-art waterjet cutting technology, Medalco can take both MDF and plywood to the next level.

- For MDF: Waterjet allows us to carve detailed patterns, custom grooves, and intricate panel designs that traditional saws can’t achieve.

- For Plywood: Precision cutting ensures tight joints and seamless integration with stone countertops, backsplashes, and hardware.

Imagine a kitchen cabinet door with an inlaid stone medallion cut by waterjet. That’s not just carpentry, it’s functional art.

Aesthetic Value: Finishes, Textures, and Customization

Designers love MDF for its blank-canvas quality. It can be painted any shade, from matte black to vibrant teal, without visible grain lines. Plywood, on the other hand, shines when you want natural warmth.

At Medalco, we’ve created Scandinavian-style plywood kitchens and sleek contemporary MDF cabinets with high-gloss finishes. The right material sets the tone for the whole space.

Durability in Real-World Use

In day-to-day use, plywood outperforms MDF in strength. We’ve seen MDF cabinet doors sag under heavy hardware, while plywood stayed solid. However, in non-structural elements like floating shelves or painted doors, MDF holds its own.

Moisture and Heat Resistance

Kitchens and bathrooms bring unique challenges: steam, spills, and heat. MDF swells when exposed to water, while plywood resists it better. Medalco recommends plywood bases for sink cabinets but allows MDF doors for painted elegance.

Cost Analysis: Which One Truly Saves Money?

While MDF is cheaper upfront, consider long-term replacement costs. A warped MDF cabinet near a dishwasher may require replacing sooner. Plywood’s higher upfront cost often pays off in durability.

Environmental & Eco-Friendly Considerations

Both MDF and plywood use adhesives that may contain formaldehyde, but eco-certified options exist. Medalco sources CARB-compliant, low-emission panels whenever possible.

Case Study: A Medalco Kitchen Transformation

In a recent San Jose remodel, the client wanted sleek matte-black cabinetry with stone accents. We used MDF doors with waterjet-carved details paired with plywood structural boxes. The result? Stunning aesthetics with long-term reliability.

Case Study: Commercial Cabinets & Plywood Longevity

For a tech office in Mountain View, Medalco built plywood cabinetry for high-traffic breakrooms. After five years, they still look brand new, proof that plywood thrives in commercial environments.

Artistic and Architectural Value

Cabinets are no longer just boxes. With waterjet technology, Medalco blends wood and stone, creating cabinets that double as architectural statements. Imagine walnut plywood paired with a marble inlay, precision-cut with waterjet.

Common Myths About MDF vs. Plywood

- Myth 1: MDF is always cheap and low-quality.

- Myth 2: Plywood never warps.

- Myth 3: You can’t get luxury design with MDF.

At Medalco, we’ve proven these myths wrong by combining precision cutting, advanced finishes, and hybrid designs.

When to Choose MDF

- Budget-friendly projects.

- Painted cabinetry designs.

- Intricate detailing via CNC or waterjet.

When to Choose Plywood

- Structural components in kitchens and bathrooms.

- Natural wood-look designs.

- High-traffic or commercial spaces.

Hybrid Cabinet Solutions

Why choose one? Many Medalco projects use MDF for doors (paint-ready) and plywood for cabinet boxes (durability). This hybrid method delivers best of both worlds.

What Designers & Builders Should Know

Before committing to MDF or plywood, factor in:

- Budget vs. longevity.

- Finish preferences.

- Moisture exposure.

- Custom detailing needs.

Maintenance & Longevity Tips

- Seal all edges of MDF to protect from moisture.

- Use quality hardware to prevent sagging.

- Keep plywood cabinets conditioned in humid climates.

- Regularly clean with non-abrasive cleaners.

Conclusion: Which Is Better?

The answer depends on your project. MDF shines for sleek, painted designs with detail. Plywood dominates for structural strength and moisture resistance.

At Medalco, we don’t just choose one, we customize every cabinet solution to match the client’s design goals, budget, and lifestyle.

Frequently Asked Questions (FAQs)

| 1. What is the main difference between MDF and plywood? MDF (Medium-Density Fiberboard) is made from wood fibers bonded with resin, while plywood is constructed from thin layers of wood veneer glued together in alternating directions. |

| 2. Is MDF strong enough for kitchen cabinets? Yes, MDF can be used for kitchen cabinets, but it is generally less durable than plywood, especially in high-humidity environments. Medalco often recommends plywood for long-term durability. |

| 3. Why do some people prefer MDF over plywood? MDF offers a smoother surface, making it ideal for painted finishes and detailed designs. It is also more affordable than high-grade plywood. |

| 4. Which is more resistant to moisture, MDF or plywood? Plywood is more resistant to moisture and warping compared to MDF. For bathrooms or kitchens, Medalco suggests plywood for its stability. |

| 5. Can MDF hold screws as well as plywood? Plywood holds screws and fasteners much better than MDF. MDF can split or crumble under heavy fastening. |

| 6. Which material is more eco-friendly? Plywood tends to be more eco-friendly, especially when sourced from sustainable forests. MDF often contains resins with formaldehyde, although some newer types are low-VOC. |

| 7. Is MDF cheaper than plywood for cabinet making? Yes, MDF is usually less expensive. However, plywood may provide better long-term value because it lasts longer and requires fewer replacements. |

| 8. Can waterjet cutting be used on MDF and plywood? Yes. Medalco uses advanced waterjet cutting technology for both MDF and plywood to achieve precise, intricate designs without burning the edges, unlike laser cutting. |

| 9. Which material is better for custom fabrication and detailing? MDF is excellent for detailed carving, engraving, or painted surfaces, while plywood excels in structural strength and natural wood aesthetics. |

| 10. How do I choose between MDF and plywood for my cabinets? Your choice depends on budget, location, and design goals. For painted cabinets with detailed finishes, MDF works well. For long-lasting, strong cabinets, especially in kitchens, plywood is the better option. Medalco experts help clients make the right decision based on project needs. |

Trusted External Resources

- Natural Stone Institute – Stone Selection Guide

- Architectural Digest – The Art of Book-Matching Stone

- Stone World Magazine – Fabrication Best Practices

- American Society of Interior Designers (ASID)

- International Surface Fabricators Association (ISFA)