get in touch

Have Questions?

Just add your email and hit subscribe to stay informed.

We send our newsletter once a month, and we respect your privacy.

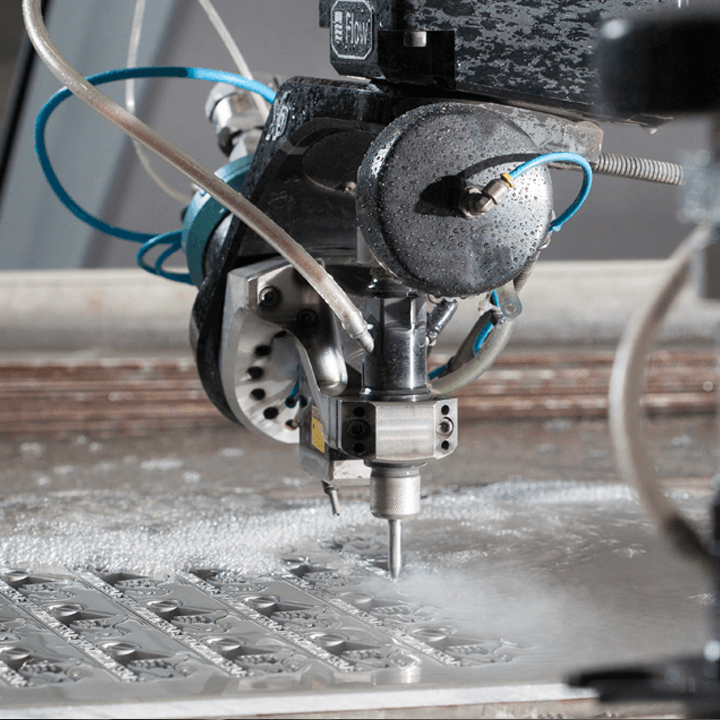

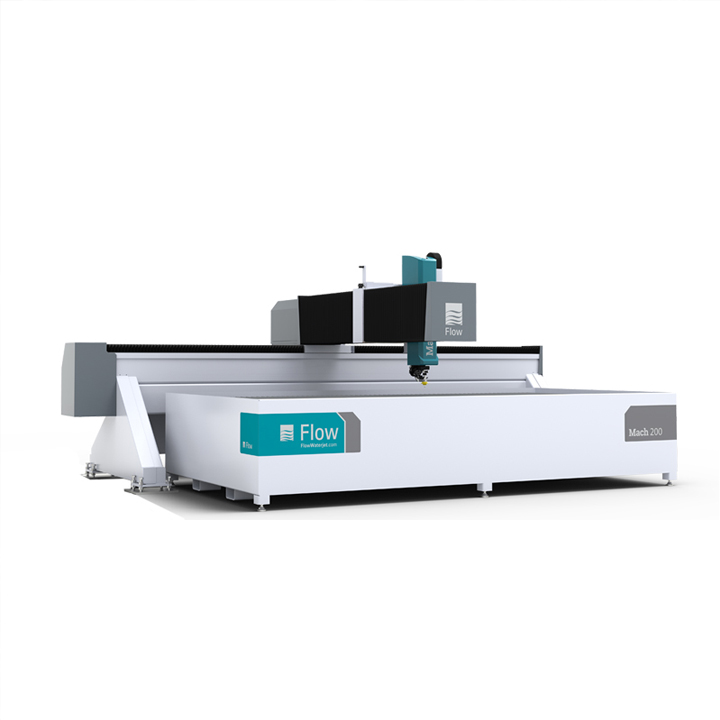

Precision waterjet cutting services from Medalco provide close tolerance, distortion-free parts with superior edge quality, no burrs, and little need for secondary finishing. We are skilled in both architectural and industrial cutting of high-quality parts from any type of metal or industrial plastic and can also handle other materials such as rubber, glass, tile and stone. A critical part of our service is to ensure customer satisfaction. You will be welcomed by a member of our professional staff when you call Medalco, not an automated answering system.

Complex metal parts, especially if the design includes sharp angles and unusual shapes, can be very difficult to cut with extreme precision. Thanks to Pivot+ head, here at Medalco, we can deliver various cuts and finishes plus bevel cutting. With 5-axis head the accuracy of cuts and bevel cuts are so high. We specialize in high quality architectural and industrial cutting of any form of metal or industrial plastic, and can also handle other materials, such as concrete, steel, tile and stone.

Compared with other fabrication techniques, waterjets can handle just about any material or product that a traditional cutters can. In addition, materials like plastics, rubber, laminated materials, stone, glass, or materials with uneven surfaces can all be handled through waterjet cutting.

Since Waterjet cutting does not generate extreme heat it does not change the properties of metal nor causing any thermal distortion. On the other hand this can occur with laser cutting.

Abrasive Waterjets will typically use garnet as the abrasive material.Garnet is non-reactive that is biologically inert. Waterjets also use much less water than may imagine thanks to its closed-looped system.

Abrasive Waterjets will typically use garnet as the abrasive material.Garnet is non-reactive that is biologically inert. Waterjets also use much less water than may imagine thanks to its closed-looped system.

Waterjets cut with fine sanded-blasted surface finish, which makes it easier to make a high-quality weld for that part. Laser cut material appears to have a rougher, scaly edge which may require additional work and machining to clean up.

Just add your email and hit subscribe to stay informed.

We send our newsletter once a month, and we respect your privacy.